Details Makc the Difference

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

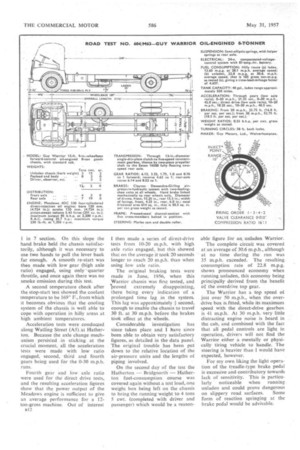

Guy Warrior 8-tonner has Meadows Oil Engine and Five-speed Gearbox : Heater and Windscreen Washers as Standard in Part-plastics Gab

By John F. Moon, A.M.I.R.T.E.

A13UNDANT attention to detail has accompanied the design of the Guy Warrior range of goods chassis. Examples of this are to be seen in the rubber mountings of the spare-wheel carrier, the provision of twin air-operated windscreen . wipers and washers, and the specification of twin driving mirrors as standard equipment.

Mechanically, the chassis layout offers a large safety margin for carrying a full payload over unfavourable road surfaces. This robustness has not been accompanied by any sacrifice in fuel economy, and the 15-ft. 9-in, wheelbase model lested showed up particularly favourably on a 47.6-mile fuel-consumption test over a hilly trunk route, 13.65 m.p.g. being returned at an average speed of 28.1 m.p.h.

Up-to-date Design Although introduced nearly two years ago, the Warrior goods chassis is still one of the most up-to-date designs in its class. It was first described in the November 11, 1955, issue of The Commercial Motor, and this chassis was evolved from the Big Otter, which was powered by a Gardner 4LW oil engine and exhibited at the 1954 Commercial Motor Show at Earls COurt.

Its specification includes twoleading-shoe brakes at both axles with air-hydraulic actuation; a hydraulically operated clutch; Marks heavyduty cam and double-roller steering gear, as fitted to chassis in the maximum-capacity Invincible range; helper springs at the rear axle; and the use of plastics for the cab panels.

A Meadows 4IDC 330 5.43-litre four-cylindered oil engine powers the chassis. This develops 85 b.h.p. at 2,200 r.p.m., and is mounted as a unit with the Meadows five-speed

constant-mesh gearbox. Two versions of this gearbox are offered: one with an overdrive-top unit, as fitted

to the test vehicle, and another with direct-drive top. The road-test. performance showed that the overdrivetop gearbox does little to impair the performance of the laden chassis and gives outstanding economy when running unladen.

An Eaton two-speid axle was incorporated in the test chassis, but it was unfortunate that the choice of gearbox and axle ratios coincided at certain points throughout the gear range; with the result that instead of there being 10 available forward gears there were only nine. This overlapping does not occur, however, to such a great extent when the directdrive-top gearbox is fitted.

The chassis frame is constructed from 1—in.-thick steel pressings, the side-members having 3-in. flanges and a maximum depth of 9 in. Fitted bolts and reamed holes are used throughout the assembly, ensuring a strong construction and easy replacement in the event of frame damage. The standard cab employs several steel pressings common to other models in the Guy range, but the wings, wheel arches, lower front pane, radiator grille louvres, threepiece engine cowl and instrument mounting panel are plastics mouldings, made in the Guy factory.

Fixed windscreens are the standard equipment, but singleor doubleopening. screens can be supplied to request, as also can rear corner lights, swivelling front quarter lights and a sliding rear window. Homemarket cabs have heaters as standard fittings, and for tropical conditions a doAple-skinned roof is offered.

The teSt chassis, ready for the road, was found to weigh 3 tons 151 cwt. prior to the test, and when laden with two boxes of test weights its gross weight was recorded as 11 tons 181 cwt. With driver and passenger aboard, the Warrior was running at 12 tons 2 cwt. The manufacturers' maximum rating is 12 tons, therefore even with extremely light bodywork it would' be difficult to carry a true 8-ton payload without slight overloading. This overload would be well within the capacity of the chassis, however.

The laden-consumption run formed the subject of the first test. This was conducted from Hatherton, on the A5 road, to Bridgnorth and back, via Shifnal. This is a hilly course, half of which is over main roads, and the total Circuit was 47.6 miles long.

Fairly heavy traffic was encoun

tered during the run and further complications were caused by extensive road works on the A5. The outward journey was completed at an average speed of 28.6 m.p.h. and the use of 13.25 pints of fuel indicatv..1 a consumption rate of 14.4 m.p.g.

Traffic conditions were slightly more unfavourable on the return journey, with the result that an average speed of 27.7 m.p.h. resulted and the fuel-consumption rate was 12.9 m.p.g. The average speed and fuel-consumption rates for the complete journey are 28.1 m.p.h. and 13.65 m.p.g., which are reasonable and give a time-load-mileage factor of 4,637. I have been given, to understand that since this test was made changes to the fuel-injection equipment have given a considerable improvement in consumption.

Throughout these runs the road speed was kept between 30 and 35 m.p.h. and overdrive gear, high-axle ratio, was used above 27 m.p.h. wherever conditions would permit. Because top gear with low-axle ratio engaged gives a lower overall ratio than fourth gear with high-axle ratio engaged, it was possible to complete much of the journey without changing the main gearbox ratios, driving solely on the Eaton axle. This technique reduces driving strain on long journeys.

At Bridgnorth an ascent of Hermitage Hill was made in an ambient temperature of 81° F. Hermitage Hill is approximately 1-mile long and has an average gradient of 1 in 12. Near the top of the hill there is a steep section of 1 in 7.

At the bottom of the hill the engine coolant temperature was found to be 160° F., and a brisk climb was then made from a standstill in 4 minutes 40 seconds. The climb produced a temperature rise of 15° F. only, and at no time was there any sign of smoking at the exhaust outlet.

The lowest gear used was second, with low-axle ratio engaged, and this ratio was used for 2f minutes at a road speed of 11 m.p.h. Because of the newness of the Eaton axle, the mechanism stuck during a snap change treat low to high ratio, and this almost brought us to a standstill. But for this, the climbing time would have been appreciably reduced.

Two descents of the hill were made in neutral, the foot brake being applied on each occasion to restrict the speed. On the first test the road speed was kept down to 15 m.p.h. then a crash stop from 20 m.p.h. at the bottom of the hill produced a Tapley meter reading of 49 per cent. During the second descent the speed was held at 20 m.p.h.. but an emergency stop at the bottom showed 47 per cent. braking efficiency, indicating slight fade, accompanied by the pronounced smell of hot facings.

The hill was climbed a second time and the Warrior was stopped on the

1 in 7 section. On this slope the hand brake held the chassis satisfactorily, although it was necessary to use two hands to pull the lever back far enough. A smooth re-start was then made with low gear (high axle ratio) engaged, using only -quarter throttle, and once again there was no smoke emission during this test.

.A second temperature check after the stop-start test showed the coolant temperature to he 169° F., from which it becomes obvious that the cooling system of the chassis is well able to cope with operation in hilly areas at high ambient temperatures.

Acceleration tests were conduced along Watling Street (AS). 'at Bather-. ton. Because the axle change mechanism persisted in sticking. at. the crucial Moment, all the acceleration tests were made with low ratio engaged, second, third and fourth gears being used for the 0-30 m.p.h. runs.

Fourth gear and low axle ratio were used fcir the direct drive tests, and the resulting acceleration figures show that the power output of the Meadows engine is sufficient to give an average performance for a 12ton-gross machine. Out of interest I then made a series of direct-drive tests from 10-20 m.p.h. with high axle ratio engaged, but this showed that on the average it look 20 seconds longer to reach 20 m.p.h. than when using low axle ratio.

The original braking tests were made in June, 1956, when this Warrior chassis was first tested, and proved extremely disappointing, there being every indication of a prolonged time lag in the system. This lag was approximately second, enough to enable the chassis to travel 30 ft. at 30 m.p.h. before the brakes took effect at the Wheels.

Considerable inVestigation has since taken place and I have since been able to obtain very satisfactory figures, as detailed in the data panel. The original trouble has been put down to the relative location of the air-pressure units and the lengths of piping involved.

On the second day of the test the Hatherton Bridgnorth Hatherfon fuel-consumption course was covered again without a test load, one weight box being left on the chassis to bring the running weight to 4 tons 5 cwt. (completed with driver and passenger) which would be a reason

able figure for an unladen Warrior.

The complete circuit was covered at an average of 30.6 m.p.h., although at no time during the run was 35 m.p.h. exceeded. The resulting. consumption rate of 22.8 m.p.g. shows pronounced economy when running unladen, this economy being principally derived from, the benefit of the overdrive top gear.

The Warrior has a top speed of just over 50 m.p.h., when the overdrive box is fitted, while its maximum speed with the direct-drive gearbox is 41 m.p.h. At 30 m.p.h. very little distracting engine noise is heard in the cab, and combined with the fact that all pedal controls are light in operation, drivers will not find the Warrior either a mentally or physically tiring vehicle to handle. The steering is heavier than I would have expected, however.

For my own liking the light operation of the treadle-type brake pedal is excessive and contributory towards lack of sensitivity. This is particularly noticeable when running unladen and could prove dangerous on slippery road surfaces. Some form of reaction springing at the brake pedal would be advisable. The suspension was good, a particularly smooth ride being given when running unladen. Dampers can be fitted to the front axle, if requested, but for normal running in this country would hardly be necessary. The adjustable driving seat is comfortable, and access to it over the rather high wing line is no worse than average for a forward-control layout.

Braking Troubles Cured Now that the braking troubles of the Warrior have been cured, the performance of the chassis is ge3erally satisfactory and it should prove attractive to operators of this class of chassis. In addition to the 15-ft. 9-in, wheelbase model tested, 'there are 10-ft. 6-in. and 13-ft. 9-in. wheelbase chassis, and a 9-ft. wheel

base prime mover. This latter is rated for a gross train weight of 17 tons.

At the Guy works I was able to carry out a series of maintenance tests to assess the accessibility of 'those running components which should receive periodic attentien.

The level of the water in the radiator was verified in 20 seconds, the filler cap being concealed beneath a hinged motif on the front panel. It took me 13 seconds to remove the plastics bonnet top, and with this removed the engine oil level was checked in 18 seconds. Replacement of the •cowl occupied a further 21 seconds, so it would be seen that an engine oil check takes nearly a minute. A hinged panel in the cowl would reduce this time by half, Filler and level plugs are provided in the gearbox and rear axle, and it took half a minute in each case to remove and replace these. The brake-fluid reservoir, which is located in the cab behind the driving seat, is easy of access and the fluid level in it was checked in 134 seconds. An even easier check concerned that of the windscreen-washer reservoir: This has a glass container and it took only a second to see whether it was full or not.

There are two 12v. batteries, and these arc attached to the right-hand frame longitudinal directly behind the cab, protection being provided by separate lids with spring clips. 1 was able to check the levels in the 12 cells in exactly one minute, but it occurred to me that although the high mounting position protects the batteries from road dirt, it might make accessibility a little more difficult when a body is fitted.

Adjustment of the brakes at the four wheels occupied 4 minutes 11 seconds. When doing this I jacked up the two wheels of each axle simultaneously, and was relieved to find that there was only one adjuster per wheel and the same spanner (4in. B.S.F.) fitted all four adjusters. The air pressure in the reservoir was then reduced to about 20 p.s.i. and

die braking system was bled in 2 minutes 50 seconds.

Several tasks were carried out on the power unit, the first of these being to change the fuel-filter element. The filter is reasonably easy to reach, being mounted centrally above the engine, and removal of the element occupied 28 seconds, replacement taking a further 48 seconds.

Injector Maintenance

The four fuel injectors were then removed in seven minutes, of which time minutes was accounted for by the removal of the air cleaner. Replacement of the injectors took eight minutes.The fuel system was then completely bled in 1 minute 14 seconds. I found it easier to prime the fuel-lift pump from below the engine, because it is difficult to reach from above.

Checking the level of the oil in the air cleaner took 37 seconds, and I was surprised to see that a hexagonal nut—as opposed to a wing nut—secured the air cleaner cover. This necessitated the use of a spanner and could be a possible deterrent to frequent attention.

As a final check, I changed a fuse in 40 seconds. The fusebox on the left side of the engine cowl is easy to reach and the fuses have replaceable wires, which means that it is necessary to carry only spare fuse wire and not a box of complete fuses.