ROADSIDE AND GARAGE.

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

A Page for Drivers, Mechanics and Foremen.

A Steam Wagon Forecarriage Repair.

The sender of the following communication has been awarded the extra payment of 5s. this week.

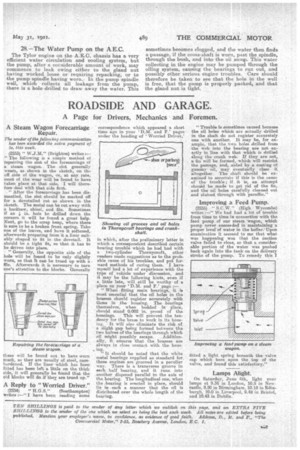

(2253) " (Brighton) writes " The following is a simple method of repairing the slot of the forecarriage of a steam wagon. The slot generally wears, as shown in the sketch, on the off side of the wagon, or, at any rate, most of the wear will be found to have taken place at thatside. I will therefore deal with that side first.

" After the forecarriage has been dismantled, the slot should be marked off for a dovetailed cut as shown in the sketch. The metal can be cut away with a hacksaw, chisel, and file. Sometimes if an in. hole be drilled down the corners it will he found a great help. Next, go to the scrap heap, where there is sure to be a broken front spring. Take one of the leaves, and have it softened, afterwards preparing from it a liner suitably shaped 'to fit in the dovetail. It should be a tight fit, so that it has to be driven into place. " Generally, the opposite side of the hole will be found to be only slightly worn, so that It can be trued up with a file. Afterwards it is necessary to turn one's attention to the blocks. "Generally

these will be found not to have worn much, as they are usually of steel, casehardened. If the liner which has been fitted has been left a little on the thick side, it will generally be found that the old blocks will do if they are trued up."

A Reply to "Worried Driver."

(2234) " H.G.S." (Southampton) writes :—" I have been reading some correspondence which appeared a short time ago in your 'DM. and F.' pages under the heading of 'Worried Driver,' in which, after the preliminary letter in which a correspondent described certain bearing trouble which he had had with a two-cylinder Thornycroft, other readers made suggestions as to the probable cause of his troubles, and put forward methods of curing them. I have myself had a lot of experience with the type of vehicle under discussion, and it may be the following hints, even if a little late, will still be worthy of a place on your `DIU. and F.' page :— "When fitting main bearings, it is most easential that the oil holes in the brasses should register accurately with those in the housing. The bearings themselves, when bedded in Place, should stand 0.002 in. proud of the

housings. This will prevent the tendency for the brass to work in its housing. It will also eliminate the risk of a slight gap being formed between the two halves of the bearings through which oil might possibly escape. Additionally, it ensures that the brasses are always in close contact with the housing,

"It should be noted that the white metal bearings supplied as standard for_ these engines are grooved in a peculiar way. There is a transverse groove in each half bearing, and it runs into another disposed parallel to the axis of the bearing. The longitudinal one, when the .bearing is erected in place, should lie in such a manner that the oil is distributed over the whole length of the bearing.

"Trouble is sometimes caused because the oil holes which are actually drilled in the shaft do not register accurately one with another. It may be, for example, that the two boles drilled from the web into the bearing are not exactly in 'line with that which is drilled lortg the crank web. If they arenot, a fin will be formed, -which will restrict the passage, and, aided by a coating of gummy oil, may eventually close it altogether. The shaft should he examined to ascertain if this is the cause of the trouble; if it is, an attempt should be made to get rid of the fin, and the oil holes carefully cleaned out and sluiced through with paraffin."

Improving a Feed Pump.

(2235) " S.O.W." (High Wycombe) writes :—" We had had a lot of trouble from time to time in connection with the feed pump of our steam wagon, which pump never succeeded in maintaining a proper level of water in the boiler.-Dpon examination it seemed to me that what was happening was that the meson valve failed to close, so that a considerable portion of the water was pushed back again into the tank on the delivery stroke of the pump. To remedy this I fitted a light spring beneath the valve cap which bore upon the top of the valve, and found this satisfactory."

Lamps Alight.

On Saturday, June 4th, light your lamps at 9.38 in London, 10.5 in Newcastle, 9.50 in Birmingham, 10.18 in Edinburgh, 10.0 in .Liverpool, 9.48 in Bristol, and 10,45 in Dublin.