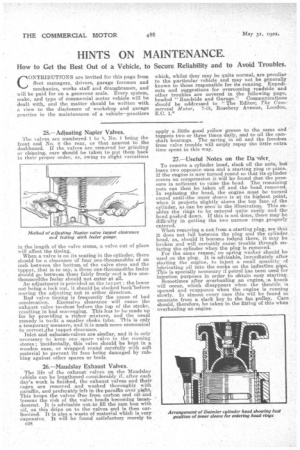

25.—Adjusting Napier Valves.

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

The valves are numbered 1 to e, No. 1 being the front arid No. 8 the rear, or that nearest to the dashboard. If the valves are removed tor grinding O1 cleaning, care should be taken to put them back in their proper order, as, owing to slight variations

in the length of the valve stems, a valve cut of place will affect the timing.

When a valve is on Its seating in the cylinder, there should be a clearance of four one-thousandths of an inch between the bottom of the valve stem and the tappet, :that is to say, a three one-thousandths feeler should go between them fairly freely-and .a five onethousandths feeler should not enter at all

An adjustment-is provided on the tappet ; the lower nut beingei lock nut, it should be slacked back`before moving the adjustingnut in either direction.

Bad valve timing is frequently the cause of had acceleration. Excessive clearance will cause the exhaust valve teeclose -before the top of the stroke, resulting.in bad scavenging. This has to be made up for by providing a richer mixture, and the usual remedy is tol•fit a smaller choke tube. This is only a temporary measure, -and it is much more economical to correctethe tappet clearance.

Inlet and exhaustevalves are similar, and it is only necessary to keep one spate valve in the running stores; incidentally, this valve should be kept in a wooden case, or wrapped round carefully with soft material to prevent its face being damaged by rubbing against other spares or tools.

26.—Maudslay Exhaust Valves.

The life of the exhaust valves on the Mandslay vehicle can be lengthened considerably if, after each day's work. Is finished, the exhaust valves and their cages are removed and washed thoroughly with paraffin, and preferably left in the paraffin over night. This keeps the valves Dee from carbon and oil, and lessens the risk of the valve head's becoming incandescent It is advisable not-to fill the 'cam box with oil, as this drips on to the valves and is then carbonized. It is also a waste of 'material which is very expensive. It will be found satisfactory merely to c38

apply a little good yellow grease to the cams and tappets two or three times daily, and to oil the camshaft bearings. The saving in oil and the freedom from valve trouble will amply repay the little extra time spent in this way.

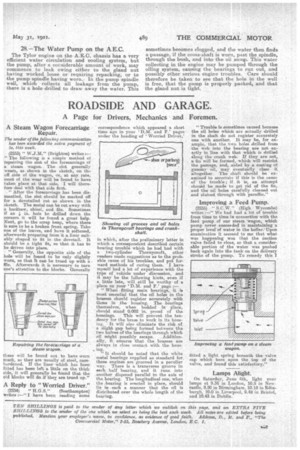

27.—Useful Notes on the Da',nler.

To remove a cylinder head, slack oft the nuts, but leave two opposite ones and a starting plug in-place. If the engine is now turned round so that its cylinder comes on compression it will be found that the pressure is sufficient to raise the head The remaining nuts can then be taken off and the heaff removed. In replacing the head, the engine must be turned round untilethe inner sleeve is at its highest point, when it projects slightly above the top face of the cylinder, as can be seen in the illustration. This enables therings to be entered quite easily and the head pushed down. If this is not done, there may be difficulty in getting the two narrow rings ,properly entered.

When removing a nut from a starting plug, see that it does not fall between the plug and the cylinder head,as, should it become lodged there, it may be broken and will certainly cense trouble through entering the cylinder when the plug is removed. For the same reason,' no spring washer should be used on the plug.. It is advisable, immediately after starting the engine, to inject a small quantity. of lubricating oil into the cocks on the induction pipe. This is specially necessary If petrol has been used for injection purposes in order to obtain easy starting. Sometimes after overhauling an engine, .1a knock will occur, which disappears when the throttle is opened and reappears when the engine is running slowly. In almost every case this will be found to emanate from a slack key in the fan pulley. Care should, therefore, be taken in the fitting of this when overhauling an engine.

28.—The Water Pump on the A.E.C.

The Tylor engine on the A.:E.C. chassis has a very efficient water circulation and cooling system, but the pump, after a considerable amount of work, may commence to leak owing either to the gland nut having worked loose or requiring repacking, or to the pump spindle having worn.. In the pump spindle well, which collects all leakage from the pump, there is a hole drilled to draw away the water. This sometimes becomes clogged, and the water then finds a passage, if the cross-shaft is worn, past the spindle, through the bush, and into. the oil sump. This water collecting in the engine may be pumped through the oiling system, causing the bearings to run out, and possibly other serious engine troubles. Care should therefore be taken to see that the hole in the well is free, that the pump is properly packed, and that the gland nut is tight.