FORD VAN POINTERS.

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

By R. T. Nicholson (Author of "The Book of the Ford ").

IAM glad to say that I am receiving a good many • queries as to the behaviour of the ammeter, because there was a time when drivers seemed to regard the ammeter as a purely ornamental fitment —put on the instrument board to make it look pretty. When they. so regarded it, they did not bother to ask questions about it: they took it for granted. Now that I am getting a regular fioy of queries about the ammeter I know that drivers are beginning to realize that ammeter readings are important : and they are!

355.—That Ammeter Again.

The leading question is:

What ought I to do if the ammeter will not register ? • I have answered that question before, but I make no apology for answering it again, because the question is cropping up again and again.

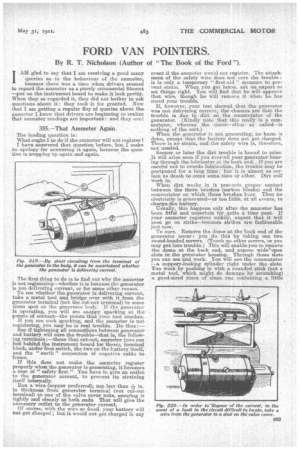

The first thing to do is to find out why the ammeter is not registering—whether it is because the generator is not delivering current; or for some other reason. To see whether the generator is delivering current, take a, metal tool and bridge over with it from the generator terminal (not the cut-out terminal) to some clean spot on the generator body. Ii the gerierator is operating, you will see snappy sparking at the points of oontaot—the points that your tool touches. If you sea such sparking, and theammeter is not registering, you may be. in real trouble. Do thus :— See if tightening all connections between generator and battery will cure the treublee—that is, the following terminals :—those that cut-out, ammeter (you can feel behind the instrument board for these), terminal block, under foot switch, the two on the battery itself, and the " earth " connection of negative cable to frame.

If this does not make the ammeter register pro.perIy when the generator is generating, it becomes a case of " safety first." You have to give an outlet to the generator current, to prevent its straining itself internally.

Run a wire (copper preferred), not less than eLe in. in thickness. from generator terminal (not cut-out terminal) to one of the valve cover nuts, securing it tightly and cleanly at both ends. That will give the necessary outlet to the generator current.

Of course, with the wire so fixed, your battery will not get charged ; but it would not get -charged in any event if the ammeter would not register. The attachment of the safety wire does not mire the trouble : it is only a temporary " first-aid " measure to prevent strain. When you get home, ask an expert to set things right You will find that he will approve that wire, though he will remove it when he has cured your trouble.

If, however, your test Showed that the generator was not delivering current, the chances are that the trouble is due to • dirt an the commutator of the generator. (Kindly note that this really is a commutator, whereas the timer—often so called—is nothing of the sort.) When the generator is not generating, no harm is done, except that the battery does not get charged. There is no strain, arid the safety wire is, therefore, not needed. • Sooner or later the dirt trouble is bound to arise: It will arise soon if you over-oil your generator bear, ,

ing through the lubricator at it back end. If you are careful not to overdo lubrication, the trouble may be postponed for a long time ; but it is almost as certain as death to come some time or other. Dirt will week in.

When dirt works in it prevents proper •contact between the three brushes (carbon blocks) and the commutator on which those brushes hear. Then no electricity is generated---or too little, at -all events, to ehergesthe battery. Usually, this happens only after the ammeter has been fitful and uneertain for quite a time past. If your ammeter registers sulkily, expect that. it will soon go on strike—because strikes are fashionable just how.

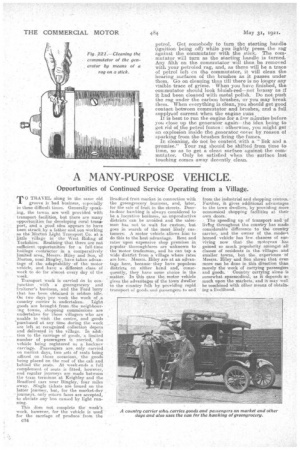

To cure. Remove the dome at the back end of the generator cover : you do this by taking out two round-headed screws. (Touch no other se-rews, or you may get into trouble.) This will enable you to remove the dome at the back end, and expose wide2opeu slots irr the generator housing. Through these slots you can see and work. You will see the commutator coppery-Iooking cylinder right under the slots. You work by pushing in with a rounded stick (not a metal tool, er'hieh might do damage by scratching) a. good-sized niece of clean rag containing a little

petrol. Get somebody to turn the starting handle (ignition being oft). while yob: lightly press the rag against the commutator with the. stick. The commutator Will turn as the starting handle is turned. Any filth on the commutator will thus he removed with your petroled rag, and, as there will be a trace of petrol left en the commutator, it will clean the bearing surfaces of the brushes as it passes under them. Go on cleaning thus till there is no longer any visible trace of grime. When you have. finished, the commutator should look bluish-red.--not brassy as if it had been cleaned • with metal polish. Do notimsh the rag under the carbon brushes, or you may break them. When everything is clean, You should get good contact hertiween commutator and brushes, and a full supplyi,of current when the engine suns

It is best to run the engine for a f.;=..w minutes before you dose up the generator again—the idea being. to get rid of the petrol fumes : otherwise, you might get an explosion inside the generator cover by reason of sparking from the brushes firing the fumes.

In cleaning, do not be content., with a "lick and a promise." Your rag should be shifted from time to time, so as to get a clean surface:sigainst the cam-, mutates,. Only be satisfied When_ the surface last touching comes away decently clean.