POINTS IN VAN BODY CONSTRUCTION.

Page 9

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

Advice to Prospective Purchasers. Body Styles, Capacities, and Constructional Features. Notes on Materials.

THERE ARE many pitfalls for the unwary purchaser of a commercial vehicle body. In many .cases,a a really good chassis is entirely spoilt by the addition of a cheap and nasty body, which is fittedchiefly because, after laying out a sonsiderable amount of money in the purchase of the chassis, the buyer endeavours to cut the cost

of the body without thinking that this part of the vehicle is of very great importance. The result is that there ie a growing discontent amongst users, because the bodies fitted to their vehicles will not stand the test of time.

It is impossible to expect a good quality article at a low quality price, and the low-grade body will seldom last the life of even the. cheapest chassis. Many of the vehicles running at the present time are equipped with bodies which are obviously 'thrown together" from inferior materials. The metal panels crinkle, bulge, and break loose; the roofs leak ; and the doors, when these are fitted, jam or swing loose. Paint may cover a multitude of sins, and it is, therefore, unwise to be deluded into purchasing a body because of its external appearance. A good-class van body for a capacity of one ton is priced from 290 to 2150, according to the finish and fittings required. Such prices may appear somewhat high, but British-built bodies are made to last and not merely to sell; that they do so is shoWn by the fact that many of them are in comparatively good condition after 10 or 15 years' running, whereas ma-ny foreign manufacturers will only guarantee their" bodies fer three months. In addition to this, cheap bodies are often turned out on what is termed "mass-production" methods, which usually imply the lowest-priced materials, and the bodies cannot be modified to suit individual tastes or the requirements of particular trades.

it is impossible to specify the styles of bodies to be used. This is a, matter for the purchaser, in which he must use hie own discretion, preferably advisedtby the coachbuilder. It is a good plan to examine the -bodies of vehicles used in tradeessimilar to that of the -purchaser. It must be remembered that the use of a neat, well-proportioned, and wellfinished body is one of the biggest incentives to Successful trading, and forms a striking advertising medium.

Caterers, grocers, and other tradearnen dealing with small packages will, usually, require their vehicles to befitted up with racks, shelves, etc., but such additions should not be made unless really necessary, as it is surprising how they add to the cost of the body.

The actual capacity of a, body depends almost entirely upon the class, or classes, of goods to be carried. If the goods are bulky, but light, a lightly built, boarded, tilt body of large cubical content can be usefully employed, but, if the goods are heavy and comparatively small, such a body only tends to

overloading, and. it is far better to employ a stronger and -smaller type. Light goods can often be carried on the roofs and, it is convenient to have a rail fitted round the latter for this purpose.

With a large body it is preferable to have a separate cab for the driver, as the headroom is not then so groat and the vehicle is much more sightly. A separate cab also saves weight and a certain amount of material.

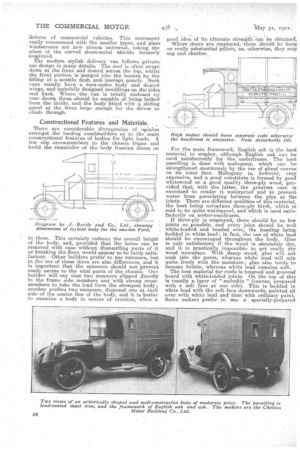

A very convenient body for general purposes is formed by a light lorry type with removable hoops and loose sheet, and this is considerably less expen sive than the close-boarded tilt type. Whilst on the subject of body capacities, we would warn prospective users against the practice .0fAttine commercial bodies on to private car chassis. This is very rarely, if ever, a successful combination. One great trouble experienced with such chassis is the usual .rise in the frame; others are that the steering position is usually far too low, the gearing too high, and the track often somewhat narrow, as also is the frame. There is a tendency 'to give more protection to D17 drivers of commercial vehicles. This movement really commenced with the smaller types, and glass windscreens are now almost universal, taking the place of the curved sheet-metal shields formerly employed. The modern. stylish delivery van follows private car design in many details. The roof is often swept down at the front and domed across the top, whilst the front portion is merged into the bonnet by the fitting of a 'scuttle dash and inswept panels. Suoh vans usually have a turn-under body and domed wings, and tastefully designed mouldings on the sides and back. Where the van is totally enclosed by rear doors, these should be capable of being locked from the inside, and the body fitted with a sliding panel at the front large enough for the driver to climb through.

Constructional Features and Materials.

There are considerable divergencies of opinion amongst the leading coachbuilders as to the mein constructional features of bodies for light loads. A few clip cross-members to the chassis frame and build the remainder of the body framing direct on

to these. This certainly reduces the overall height of the body, and, provided that the latter can be removed with cm& without dismantling parts of it or breaking the floor, would appear to be fairly satisfactory. Other builders prefer to use summers, but in the use of these there are also differences, and it is important that the summers should not prevent ready access to the vital parts of the chassis. One builder will say that two summers clipped directly to the frame side members and with strong crossmembers to take the load form the strongest body; another prefers two summers, disposed one at each side of the centre line of the body, and it is better to examine a body in course of erection, when a good idea of its ultimate strengih—Cati be obtained. Where doers are employed, these should be hung on really substantial pillars, as, otherwise, they may sag and chatter...

For the main framework, English ash is the best material to employ, although English oak can be used satisfactorily for the underframe. The best panelling is done with mahogany, which can be strengthened enormously by the use of glued canvas on its inner face. Mahogany is, however' very expensive, and a good substitute is formed by good whitewood or a good quality three-ply wood, provided that, with the latter, the greatest care is exercised to render it waterproof and to prevent water from percolating between the plys at the joints. There are different qualities of this material, the best being aeroplane three-ply birch, which is said to he quite waterproof, and which is used satis

factorily on motor-omnibuses. ._

If three-ply is employed, there should be as few joints as possible, and every joint should be well white-leaded and beaded over, the beading being bedded in white lead in fact, the use of white lead should be encouraged throughout the body. Glue is only satisfactory if the woad is absolutely dry, and it is practically impossible to get really dry wood nowadays. With damp wood, glue will not soak into the pores, whereas white lead will mix quite freely with themoisture.' glue also tends to become brittle whereas white lead remains soft.

' The best material for roofs is tongued and grooved board with white-leaded joints. On the top of this is usually a layer of "moleskin" (canvas, prepared with a soft face at one side). This is bedded in white lead with the soft face downwards painted all over with white lead and then with ordinary paint. Some makers prefer to use a specially-prepared

canvas,. with the outer-side covered with a smooth composition. This is particularly useful where articles have to be carried on the roof.

. To prevent wrinkling, the moleskin is som.etimes soaked in boiled linseed oil before stretching over the roof ; this also assists in rendering it waterproof. The doors should have almniniturn door plate right round them-, and, if they are curved in at the top and bulge out towards the bottom, the water will tend to run off and not into the vehicle.

Metal panels—usually lead-coated iron—have to be employed where there is a curve in two directions. They are also extensively employed in the cheaper types of bodies. When so used, they should be entirely free from rust and perfectly dry, and it is necessary to use a proper priming co-at, as chemical action may occur betwee.n ordinary paint and the metal. The priming material can be obtained from almost any of the leading paint manufacturers. A considerablb amount of trouble is sometimes caused through the rusting of metal panels. This roughens the surface of the paint and eventually causes it to flake off. Apart from their cheapness, however, metal panels have the advantage that they will not break when hit, but will dent, and such dents can be hammered out fairly easily, whereas with wood panels the whole panel may have to be replaced. They are very apt, however, to chatter and buckle, and the locks to get out of adjustment, with the result that the best coachbuilders seldom recommend them.

In the construction of the frames, only English ash should be employed. American ash is kilndried, is much lighter, and is often so spongy that the scfiews will pull out of it. American white lead is also often of a very inferior quality and adulterated with chalk.

The weight of a body is of considerable importance, and it should never exceed the maximum allowed by the makers. Where this maximum is not specified, it is usual to take the weight of the body as between one-quarter and one-third of the load capacity. '

On no account should holes be drilled in the chassis frame unless .with the permission of the manufacturers, as frames are sometimes none too strong.