Limited opportunities for garage workshops

Page 118

Page 119

If you've noticed an error in this article please click here to report it so we can fix it.

• Speed limiters become a mandatory fitting next year on new coaches going into service from the beginning of April. Legislation compelling their use on trucks has yet to be promulgated in the UK, although in a growing number of fleets, speed limiters (also sometimes called cruise control devices or road speed governors) are being specified.

While employed drivers are instinctively against such equipment, their arguments are usually without substance, against the background of a 96km/h (60mph) motorway speed limit for goods vehicles of over 7.5 tonnes gross vehicle weight.

Many transport managers have realised that, apart from obvious safety considerations, most modern high-horsepower heavy trucks are deliberately endowed with "long-legged" gearing, so that at the motorway maximum, the engine is turning over at, or close to, its most economical rpm. This means that on a level road, in top gear, at least with a low or streamlined semi-trailer, speeds of 115 or even 120km/h are attainable.

Where speed limiters are fitted to trucks or coaches, under protest from drivers, it follows that the installation needs to be tamper-proof. More specifi cally, if a driver has interferred with the speed-limiter, evidence of the fact needs to be readily visible.

To the chagrin of the speed limiter suppliers and to the surprise of public service vehicle operators, the new legislation does not call for fitting by approved installers or for periodic checking, equivalent to the strict installation and calibration requirements relating to tachographs.

Suppliers like Lucas Kienzle, with a tachograph background, are nevertheless naturally keen to see that their equipment is installed to laid-down standards; LK has therefore appointed about 100 fitting agents, most of them Dip-listed tachograph fitting/calibration centres.

There is nothing to prevent speed limiter agents selling, over the parts counter, limiters and installation kits, though they are naturally discouraged from doing so. Having spent an hour and a half watching an LK-approved installer, Chassis Developments, of Leighton Buzzard, fitting a unit, I can understand the inordinate difficulties which would be encountered by a fitter in an average, moderately equipped fleet workshop.

Most current-model trucks have electronic tachographs generating eight pulses per propshaft revolution, from which an input signal to the speed limiter control module can be fed directly. When an older mechanically driven tacho is fitted, a socalled sender unit most be interposed at the gearbox drive point, to generate the electronic pulse signal needed by the control module,

It adds around 270 to the 2400-2450 installed price of the LK speed limiter. Like other components in the installation, the sender, once in place, should be sealed against tampering. Bright red seals are supplied by LK; it is visibly obvious if they are subsequently broken/removed.

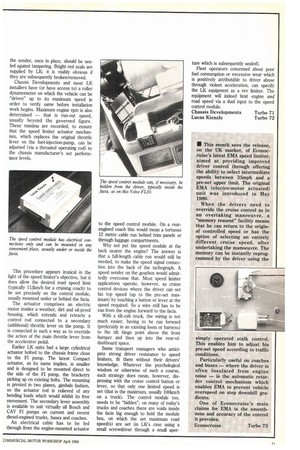

Chassis Developments and most LK installers have (or have access to) a roller dynamometer on which the vehicle can be "driven" up to its maximum speed in order to verify same before installation work begins. Maximum engine rpm is also determined — that is run-out speed, usually beyond the governed figure. These maxima are recorded, to ensure that the speed limiter actuator mechanism, which replaces the original throttle lever on the fuel-injection-pump, can be adjusted (via a threaded operating rod) to the chassis manufacturer's set performance levels.

This procedure appears ironical in the light of the speed limiter's objective, but it does allow the desired road speed limit (typically 113km/h for a cruising coach) to be set precisely on the control module, usually mounted under or behind the facia.

The actuator comprises an electric motor insider a weather, dirt and oil-proof housing, which extends and retracts a control rod connected to a secondary (additional) throttle lever on the pump. It is connected in such a way as to override the action of the main throttle lever from the accelerator pedal.

Earlier LK units had a large cylindrical actuator bolted to the chassis frame close to the Fl pump. The latest Compact actuator, as its name implies, is smaller and is designed to be mounted direct to the side of the Fl pump, the bracketry picking up on existing bolts. The mounting is pivoted in two planes, gimbals fashion, so the actuator rod is relieved of any bending loads which would inhibit its free movement. The secondary lever assembly is available to suit virtually all Bosch and CAV Fl pumps on current and recent diesel-engined trucks, buses and coaches.

An electrical cable has to be fed through from the engine-mounted actuator to the speed control module. On a rearengined coach this would mean a tortuous 12 metre cable run behind trim panels or through luggage compartments.

Why not put the speed module at the back nearer the engine? The answer is that a full-length cable run would still be needed, to make the speed signal connection into the back of the tachograph. A speed sender on the gearbox would admittedly overcome that. Most speed limiter applications operate, however, as cruise control devices where the driver can set his top speed (up to the pre-set maximum) by touching a button or lever at the speed required. So a wire still has to be run from the engine forward to the facia.

With a tilt-cab truck, the wiring is not much easier, having to be run forward (preferably in an existing loom or harness) to the tilt hinge point above the front bumper and then up into the rear-ofdashboard space.

Some transport managers who anticipate strong driver resistance to speed limiters, fit them without their drivers' knowledge. Whatever the psychological wisdom or otherwise of such a course, such strategy does mean, however, dispensing with the cruise control button or lever, so that only one limited speed is set (that is the maximum, usually 1001(m/h on a truck). The control module too, needs to be "hidden"; on many of today's trucks and coaches there are voids inside the facia big enough to hold the module box, on which the set maximum road speed(s) are set (in LK's case using a small screwdriver through a small aper ture which is subsequently sealed).

Fleet operators concerned about poor fuel consumption or excessive wear which is positively attributable to driver abuse through violent acceleration, can specify the LK equipment as a rev limiter. The equipment will indeed limit engine and road speed via a dual input to the speed control module.

Chassis Developments Turbo 71 Lucas Kienzle Turbo 72