Heat reflection could work wonders

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

THE VALIDITY of a statement by Mr G. Longfoot, of Wellworthy Ltd, regarding the potential merit of using a piston crown of heat-reflecting ceramic material in a diesel, quoted in Technitopics (CM January 30), has been challenged by a number of readers. And this is not surprising. It appears to conflict with the accepted principle that the aspirated air of a diesel engine and the combustible mixture of a petrol engine should be kept as cool as possible (compatible with good mixture distribution in the latter case) and with the acknowledged need to provide adequate heat paths from the combustion space to the cooling water in both cases.

Some years ago there were rumours that a compact and light form of refrigerating unit was being developed that could be applied to a diesel to give a greatly increased power output. Nothing came of the project because of the size, weight and cost of the unit, but the exercise highlighted the gains that could be obtained by super-cooling to condense the air. While refrigerating the intake air of a carburetted petrol engine would not be practical because it would make good distribution impossible, its application to a spark-ignition engine with petrol injection should be feasible.

Theoretically it would at least double the quantity of air or mixture that was drawn into the cylinder without pressure charging, and despite the fact that a diesel is a compression-ignition engine it would promote "smooth" combustion with a low rate of pressure rise. It would probably enable the compression ratio of a petrol engine to be increased by two or three ratios and provide for operation on a low-octane fuel.

Cooling

Cooling the air or mixture thus increases the volumetric or filling efficiency of an engine, but when the fuel injected in a diesel cylinder or the mixture of a petrol engine starts to burn, any cooling of the combustion chamber that is not required to prevent overheating of the working parts reduces thermal efficiency and engine output unnecessarily.

Over the years, increases in specific output have perpetuated the problem of cooling the working parts, notably the piston, sufficiently to prevent breakdown of the oil film, piston-ring sticking, scuffing and

so on. And designing a piston that will aid dissipation of heat to the cooling water through the cylinder walls has been a major preoccupation of engine and piston makers.

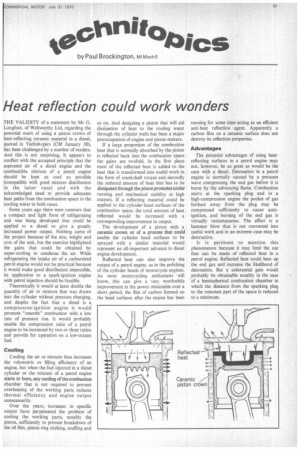

If a large proportion of the combustion heat that is normally absorbed by the piston is reflected back into the combustion space the gains are twofold. In the first place most of the reflected heat is added to the heat that is transformed into useful work in the form of crankshaft torque and secondly the reduced amount of heat that has to be dissipated through the piston promotes cooler running and mechanical stability at high outputs. If a reflecting material could be applied to the cylinder-head surfaces of the combustion space, the total amount of heat reflected would be increased with a corresponding improvement in output.

The development of a piston with a ceramic crown or of a process that could enable the cylinder head surfaces to be sprayed with a similar material would represent an all-important advance in diesel engine development.

Reflected heat can also improve the output of a petrol engine, as in the polishing of the cylinder heads of motorcycle engines. As most motorcycling enthusiasts will know, this can give a very worthwhile improvement in the power obtainable over a short period, the film of carbon formed on the head surfaces after the engine has been

running for some time acting as an efficient anti-heat reflection agent. Apparently a carbon film on a ceramic surface does not destroy its reflection properties.

Advantages The potential advantages of using heatreflecting surfaces in a petrol engine may not, however, be as great as would be the case with a diesel. Detonation in a petrol engine is normally caused by a pressure wave compressing the end gas before it is burnt by the advancing flame. Combustion starts at the sparking plug and in a high-compression engine the pocket of gas farthest away from the plug may be compressed sufficiently to cause autoignition, and burning of the end gas is virtually instantaneous. The effect is a hammer blow that is not converted into useful work and in an extreme case may be destructive.

It is pertinent to mention this phenomenon because it may limit the use that can be made of reflected heat in a petrol engine. Reflected heat could heat up the end gas and increase the likelihood of detonation. But a substantial gain would probably be obtainable notably in the case • of a hemispherical combustion chamber in which the distance from the sparking plug to the remotest part of the space is reduced to a minimum.