A 14-ton 37-ft.

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

Bus Easily Handled

By Laurence J. Cotton, NI.I.R.T.E.

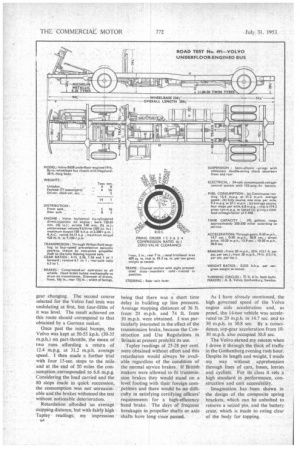

WHEN the Volvo underfloorengined bus, loaded to the equivalent of 77 passengers, tipped the scale at 14,300 kg. (14 tons) and registered 5 tons 16 cwt. imposed load on the front axle,. I visualized a herculean task before me in driving through Gothenburg and its suburbs. In this I was mistaken, because, although it was not equipped with power steering gear, the manual effort required was much less than that needed on most of its European

contemporaries.

The bus, which had been borrowed from the Gothenburg Tramways, Was withdrawn from service' for my test and had already *covered about 20,000 Miles, which may to some degree have eased the steering gear.

The problem of reducing steering effort, with almost 6 tons on the front axle and large-section tyres, has been solved by the Volvo research department in conjunction with the Gothenburg Tramways. Manual effort of 25.2 1b-ft. to move the steering wheel through one revolution with the bus travelling at B2 10 m.p.h. has been reduced by over 35 per cent., corresponding to 16 lb.-ft.

Front axles, as received from the suppliers, are stripped, checked and machined to closer limits than the original. The use of Michelin E.20 tyres as standard on the front wheels, to replace the former 11.00-in. extraply covers, has alone reduced steering effort by over 17 per cent.

Increased Castor Although not recommended by Volvo, Gothenburg Tramways have also doubled the castor angle to 30, which has made a further slight reduction in steering effort, but there is a tendency towards wheel wobble at 40 m.p.h. or more. Such a defect would not be apparent in town service.

The Volvo underfloor-engined passenger chassis is conventional in design, but has some interesting details in layout. The 9.6-litre engine is built for horizontal mounting, and has the csankshaft offset 5 in. to the right from the centre line of the valves are n o t shrouded. Power output is not affected, 150 b.h.p. being yielded at the maximum speed and 428 lb.-ft. torque is delivered at 1,100 r.p.m.

A shallow crankcase-cylinderblock casting reduces overall height below the main frame member. The fuel-injection pump is mounted transversely at the front. Hydraulic valve tappets, with constant-zero clearance, afford quieter running and reduce the need for maintenance.

Each piston has a chromium-plated top ring and the finned crankcase base is divided into wet and dry Sumps. To save time when changing the engine complete, the air filter, Bosch compressor, dynamo and fan are mounted separately on the chassis, the auxiliaries being operated by a jack shaft and belt-and-pulley train driven from the front of the crankshaft.

The fluid coupling has been altered to reduce low-speed drag and the standard setting has a stalling speed of 630 r.p.m., also the normal free idling speed of the engine, 450 r.p.m., is reduced to 350 r.p.m. when a gear is engaged. The bus-bar of the

Wilson gearbox is operated by air, which reduces pedal effort. A normal dutch and five-speed synchromesh gearbox are available as an alternative transmission system and a torque converter is at present being developed by the Volvo company.

The 19-ft. 8i-in.-wheelbase bus has a two-piece propeller shaft with a transmission drum brake linked mechanically to the hand-brake lever and fitted immediately in front of the rear axle. This drum has a bonded cast-iron lining and the rear axle is equipped with a hypoid,bevel drive.

Sensitive Braking The service brake incorporates Bosch equipment, which includes a two-cylindered compressor and independent operating cylinders at each wheel. When driving the bus I found that the brake-actuating valve mounted below the organ-type pedal was highly sensitive. The two stages of travel were not so apparent, even when carrying a full complement of passengers, as in the average British vehicle.

The chassis frame has channel-section cross-members, cold-riveted to the main longitudinals, which are parallel but cranked slightly at the rear of the engine to provide 10-in. clearance below the flywheel housing, and are swept over the rear axle. These main frame members extend 7 ft. 6 in. ahead of the front axle, hut at the rear they are cut short immediately behind the spring brackets. The Hagglunds 36-ft.-long body overhangs the rear axle by about 9 ft. 7 in. and overall length of the complete bus over the front bumper blade is almost 37 ft.

Ample Headroom The arrangement of the axles in relation to the body provides adequate room for a double-door entrance at the rear, with exits at the centre and ahead of the front wheels. The steps are easily negotiated and over 7 ft. of headroom is provided in an underfloor-engined bus of only 9-ft. 6-in, overall height.

The bus was withdrawn after the morning peak for loading, a speedometer check and general inspection before starting tests on the following day. In Sweden an allowance of 70 kg. (154 lb.) is made for each passenger and although the ballast carried was equivalent locally to 70 people, this would correspond to 77 by the British standard of 140 lb. per person. The bags were placed to correspond with normal crush-load distribution and an early start was made for a full one-day test. After driving to Landvetter, about 12 miles from Gothenburg, the bus was headed towards Partille for the long, gradual climb from sea level. Stops were made at various sections and the Volvo distinguished itself by pulling away from rest in second gear on a 1-in-10 gradient. A 6.5-to-1 final-drive ratio is used for general bus operation, but, whilst providing a good performance in traffic or on hills, it limits the maximum speed to 68 k.p.h. (42.5 m.p.h.).

The advantage of raising the governed speed from 1,800 r.p.m., which is normal in Britain, to 2,200 r.p.m., was shown in acceleration and hill climbing. Another point is that all oil engines built or operated in Sweden have venturi injection-pump governing, because some operators have experienced failure with centrifugal governors. The manufacturers confirmed that venturi equipment is also cheaper.

A consumption test with one stop per mile was run over an undulating out-and-return course, corresponding approximately to the main road between Egham and Camberley, in Surrey. Unlike the usual test conditions encountered in England, no hurried acceleration was necessary to overtake the slower traffic and stops were made without qualms.

The Volvo was driven at inter-urban service speed, that is, up to 40 m.p.h. where conditions permitted, and 1.605 gallons of fuel were used in 14.91 miles. This corresponds to 9.3 m.p.g. and the average speed, deducting standing time, worked out to 31.5 m.p.h. As the Volvo weighs more than a double-decker and was carrying the equivalent of a fully laden sixwheeled trolleybus with standing passengers, the result is indicative of high engine efficiency.

Taking control at this point, 1 drove across the outskirts of Gothenburg, immediately noticing the lightness of steering effort, particularly when negotiating some narrow side roads to avoid crossing a wooden bridge which, besides having an axleweight limit of 6 tons, was so steeply ramped as to be dangerous.

I was soon aware of the air escape every time, the compressed-air unloader valve operated and, although it might be customary to exhaust directly to atmosphere in Continental-built chassis, I prefer the silencer provided on British-built chassis.

Cab Appointments Driving was effortless and I soon felt at home. 1 was conscious of the absence of a signalling window, hand signalling being unusual in Sweden. The swivelling driving seat, the backward curve of the body front panel and windscreen, an& the shade afforded by the roof overhang beyond the cab are points that were appreciated.

In Germany, fuel tests are normally conducted over a level road and 10 per cent, is added to the result to compensate for undulations and gear changing. The second course selected for the Volvo fuel tests was undulating at first, but four-fifths of it was level. The result achieved on this route should correspond to that obtained by a German maker.

Once past the initial bumps, the Volvo was kept at 50-55 kp.h. (30-35 m.p.h.) on part-throttle, the mean of two runs affording a return of 12.4 m.p.g. at 31.2 m.p.h. average speed. I then made a further trial with four 15-sec. stops to the mileand at the end of 20 miles the consumption corresponded to 6.8 m.p.g. Considering the load carried and the 80 stops Made in quick succession, the consumption was not unreasonable and the brakes withstood the test without noticeable deterioration.

Retardation afforded an average stopping distance, but with fairly high Tapley readings, my impression being that there was a short time delay in building up line pressure. Average stopping distances of 36 ft. from 20 m.p.h. and 74 ft. from 30 m.p.h. were obtained. I was particularly interested in the effect of the transmission brake, because the Construction and Use Regulations in Britain at present prohibit its use.

Tapley readings of 25-28 per cent. were obtained without effort and this retardation would always be available regardless of the condition of the normal service brakes. If British makers were allowed to fit transmission brakes they would stand on a level footing with their foreign competitors and there would be no difficulty in satisfying certifying officers' requirements for a high-efficiency hand brake. The days of frequent breakages in propeller shafts or axle shafts have long since passed. As I have already mentioned, the high governed speed of the Volvo engine aids acceleration and, as proof, the 14-ton vehicle was accelerated to 20 m.p.h. in 14.7 sec. and to 30 m.p.h. in 30.8 sec. By a coincidence, top-gear acceleration from 1030 m.p.h. also occupied 30.8 sec.

The Volvo earned my esteem when I drove it through the thick of traffic in the Gothenburg evening rush hour. Despite its length and weight, I made my way without apprehension through lines of cars, buses, lorries and cyclists. For its class it sets a high standard in performance, construction and unit accessibility.

Imagination has been shown in the design of the composite spring brackets, which can be unbolted to remove a seized pin, and the battery crate-. which is Made to swing clear of the body for topping.