MINING WITHOUT MINER,_ to Supply the Nation's Fuel

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

WHAT is the future of coal mining? VV What is the eventual solution of dwindling production, miners' wages, absenteeism, and, most important of 'all, death in the mines? What will have unprecedented influence on the development of fuels of various kinds and for divers utilizations, including that of road transport?—Mining without miners.

This system is not the pious hope of a social reformer, but the practical realization, by the " back-room.boys," of an intensely humanitarian ideal to prevent the need for human 'beings to go down into the bowels of the earth and toil at the task of winning coal, which task carries with it little reward and the continual risk of death or disablement.

First Thought of in Russia—Tried in England

The idea was born in Russia in the Tsarist days some 50 years ago. Mandeleev wrote that the time would come when coal would not be extracted from the earth, but would be carbonized in situ, and the resulting gases brought to the surface in pipes for distribution in. the' usual way; in fact, the gasworks would be put down the mine.

It is of interest to note that the first attempt to realize this ideal was carried out in this country. Soon after Mandeleev's prophecy, Sir William Ramsay developed the idea to the exent. of sinking a shaft in the Durham coalfields, but no furtlfer developments were carried out.*

The final establishment of the system as a recognized principle in the economics of the nation was only reeently accomplished in the land of its conception under direct Government encouragement and support.

Although technical information is not yet available in much detail, owing to the short period of time that has

elapsed since the introduction of the scheme and, of course, to war conditions, there are indications that the results are such as will provide the synthesis gases from which Fischer and Tropsch have bean able to obtain such varying products, and particularly fuels. and lubricants for internal-combustion engines. The system has provided a great deal of the self-sufficiency .attained by the Germans, in spite of the disbelief, real or simulated, of 'experts of other countries.

These synthesis gases--hydrogen and carbon monoxide--•---in the ratio of two to one—form the basis of much research that has been conducted in this country for several years, directed in the main to the increase in the methane concentration in town gas with the possibility of a simple gas in place of the complex one now in use for that purpose. Such a gas would lend itself to liquefaction for use as a motor fuel.

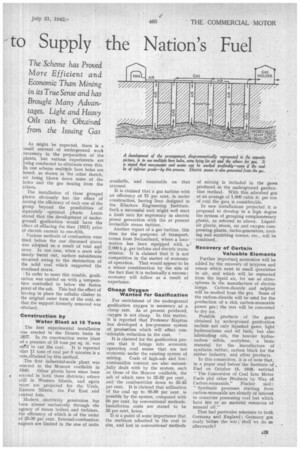

Took Practical Shape in U.S.S.R. In 1931 The instigator of the research in Russia was Lenin, even in those old, last years of Tsarisrn in la19: he had read of Ramsay's attempt and set out to inspire the scientists of those days. It was not until 1921, however, that the scheme was launched in its practieal,experimental shape with a Governmental niandate. Shafts were sunk in several parts of the country: the outline • of the scheme was as shown in an accompanying sketch.

Two shafts are sunk and steel-lined. Down one of them a blast of heated air is blown. The coal between the two .shafts is electrically ignited and the gas formed by the combustion of the burning coal passes up the second shaft for• distribution or storage as required.

Variation in the composition of the gases can be obtained by supplying air, oxygen and steam together, or separately, and in various proportions, and further, by interrupting the blow, in which case the hydrogen content of the gas is as high as 60 or 70 per cent., • adding to the products available from the system, among which are benzene, ammonia, ammonium nitrate and sulphate, nitric acid, etc.

Efficiency of operation is enhanced considerably by the grouping, for combined working, of plants for different purposes, which can each use the rejected byproducts of the others. Perhaps the best example of wasted efficiency is that of an electricity generating station using steam plant for its alternators. The efficiency of the station is of the order of 25-30 per cent, for the purpose erected, viz., electricity generation; this means to say that from 70-75 per cent., of the heat units we use for that purpose are wasted, in the form of rejected heat, unusable in a station erected purely for the purpose of electricity generation. In a combined group this rejected heat could be used to raise the temperature of the air blast for the combustion going on in the coal seam.

A chemical works has oxygen to spare, which again could be used for enriching the gases, by being added to the hot-air blast. The gas generated in the " miner-less mine " can be used to operate gas engines in a combined electricity plant, or for supplying gasengine-produced power in several associated works.

One Station Released 500 Miners from Pits One station in the Donetz basin was arranged to provide liquid fuels to a neighbouring chemical works, also synthesis gas (CO and 142) for chemical purposes. This particular underground gasworks r;leased 500 miners from a lifetime of work in the pits.

A station under construction will combine an electric power installation with a chemical works based upon the process. Power gas for driving turbogenerators on the site will be produced as well as synthesis gas. The power from the generators' will be transmitted to customers as electricity instead of as was. In th& case 1,500 miners will be brought into the light of day to dotheir daily work henceforth. As might be expected, there is a small amount of underground work necessary in the preparation of the plants, but various experiments are being conducted to eliminate even this. In one scheme multkple bore holes are bored, as shown in the other sketch, air being blown down some of the holes and the gas issuing from the others.

The installation of these grouped plants obviously has the effect of raising the efficiency of each one of the group beyond the possibilities of separately operated plants. Lenin stated that the development of undergrouna gasification would have the effect of reducing the then (1913) price of electric current to one-fifth.

Various methods of combustion were tried before the one discussed above was adopted as a result of trial and error. In one case, when a seam was nearly burnt out, surface subsidences occurred owing to the destruction of the solid coal which supported the overhead strata.

In order to meet this trouble, gasification was carried on with a temperature controlled to below the fusion point of the ash. This had the effect of leaving in place the cellular clinker in the original outer form of the coal, sso that the support formerly removed was retained.

Construction by Water Blast at 15 Tons The first experimental installation was erected in the Donetz basin in 1937. In its construction water blast at a pressure of 15 tons per sq. in: was used to cut the coal. It is reported that 11 tons of coal per 8 minutes is a rate‘altained by this method.

The first industrial-scale plant was erected in the Moscow coalfields in 1940. Other plants have since been • erected in both these districts; others still in Western Siberia, and again more are projected for the T.Jrals, Eastern Siberia, the Far East and central Asia.

• Modern,. electricity generation has been almost exclusively through the agency of steam boilers and turbines, the efficiency of which is of the order of 25-30 per cent. Internal-combustion engines are limited in the size of units available, and unsuitable on that account.

It is claimed that a gas turbine with an efficiency of 75 per cent, is under construction, having been designed in the Kharkov Engineering Institute. Such a successful unit might well start a fresh race for supremacy in electric power generation with the at present invincible steam turbine.

Another report of a gas turbine, this time for the purposes of transport, comes from Switzerland, where a loco-' motive has been equipped with, a 2;000 h.p. gas turbine and electric transmission. It is claimed that it is not competitive in the matter of economy of operation. That would appear to be a minor consideration by the side of the fact that it is technically a success; economy will follow as a result of experience.

Cheap Oxygen Wanted for Gasification For enrichment of the underground gasification oxygen is necessary at a cheap rate. As at present produced, oxygen is not cheap. In this matter, it is reported that Professor Kapitza has developed a low-pressure system of production which will effect con-siderable reduction in the cost.

It is claimed for the gasification process that it brings into economic operation coal seams that are not economic under the existing system of mining. Coals of high-ash aid low. combustible content are also success,fully dealt with by the system, such as those of the Moscow coalfields, the ash of which runs to 25-39 per cent., and the combustibles down to 85-45 per cent. It is claimed that utilization of the coal up to 80-90 per cent, is possible by the system, compared with 00 per cent.by conventional methods. Installation costs are stated to be 35 per cent, lower.

It is a point of some importance that the methane adsorbed in the coal in situ, and lost in conventional methods of mining is included in the gases produced in the underground gasification method. With this adsorbed gas at an average of 1,000 cubic ft. per ton of coal the gain is considerable.

In new installations projected it is proposed to develop to a high degree the system of grouping complementary plants, as referred to above. Liquidair plants, steam, air and oxygen compressing plants, turbo-generators, cooling and scrubbing towers, etc., will be combined..

Recovery of Certain Valuable Elements • Further important economies will be added by the recovery of krypton and xenon which exist in small quantities in air, and which will . be separated from the liquid air, for use as atmospheres in the manufacture of electric• lamps. Carbon-dioxide and sulphur will be washed from the gas. Some of the carbon-dioxide will be used for the production of a rich carbon-monoxide power gas ; the rest will be converted to dry ice.

Possible products of the gases obtained by underground gasification include not only liquefied gases, light hydrocarbons and oil fuels, but also lubricating oils, the heavier hydrocarbon solids, acetylene, a basic material fox the manufacture of synthetic rubber, carbon black for the rubber industry, and other products.

In this connection, it is of note that, in a paper read before the Institute of Fuel on October 15, 1938, entitled "The Conversion of Coal Into Motor Fuels alid other Products by Way of Carbon-monoxide," Fischer said : " Synthesis processes starting from carbon-monoxide are already of interest to countries possessing coal but which have few or no material resources of mineral oil."

. That bad particular reference to both Germany and England ; Germany got ready before the war; shall we do so afterwards?