Tiverton takes the cake

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

WN IN Devon one bodyIder at least has his workforce -king regular overtime to aplete his customers' orders 3chedule.

iverton Bodies and Coniers is to be found in the heart he West Country, but the firm lies vehicles for operations as away as the Midlands and t Anglia.

,t one time this family busis built anything and every1g from pantechnicons to k loaders. In more recent )rs production has been tred on more specialised je commercial vehicles for transportation of livestock I perishable foodstuffs.

he company has been in ;iness at the same site in ndell's Road, Tiverton, for the it 60 years and many customhave had connections with firm lasting over 30 years. +lany of Tiverton's present ;tomers are own-account :.rators, and include those h household names such as Nyers, Lloyd Maunder, Exss Dairy, Kipling Cakes, Scott ats and Plymouth Co-op. drnost all of the work is car i out in direct contact with the )rator. In this way the vehicle !cification can be matched ictly to the customer's rerements to suit his particular ;iness.

-hough business is still sonably buoyant, the corniy's managing director Mr :e told me that the recession laving its effect.

:ustomers are reluctant to ke long-term commitments, where previously orders re often for a batch of four or of a particular model, many now replacing just one icIe at a time.

The total life of the product has become even more importantr and repair and refurbishing activities have become more prominent.

One body used by a local farmer to collect his vegetable crop had originally been built in the early Sixties and was on its third visit to the factory so that damage and wear could be made good before being mounted on yet another new chassis. Only Tiverton's own bodies are accepted for refurbishing.

Today's range concentrates on bodies for rigid vehicles of over ten-ton gvw and a high percentage of semi-trailer box van bodiesr of which many are built primarily in aluminium using 16-gauge riveted outer sheeting.

Most of the frame sections are extruded from the company's own dies. One-piece grp sheets, manufactured to Tiverton's specification with an extra layer of woven roving for greater strength, are used in temperature-controlled vans.

Slab polyurethane insulation is used throughout to a thickness of 635mrn (2.5in) in the side walls, 102mm (4in) front and rear, while the greatest thickness of 140mm (5.5in) is used both in the floor and the roof.

Petter or Thermo King refrigeration equipment provide the temperature control required by ATP regulations. Modern construction techniques are not as labour-intensive, but all the old skills are available from the workforce which for the most part has been trained by the firm.

It's little used now, but the factory still retains a trim shop, complete with sewing machines — its operator has long since been retrained in the art of paint spraying.

All steel fabrications are made on the premises in the black smith shop, while hardwoodframed doors are made in the carpentry shop.

Quality is ensured by using locally grown ash, elm and beech, which is stored and airdried by Tiverton for up to four years to avoid any possibility of warping. Other types of hardwoods are imported.

Apart from the proprietary components such as tail lifts, pumps and freezing units, everything can be made on the premises.

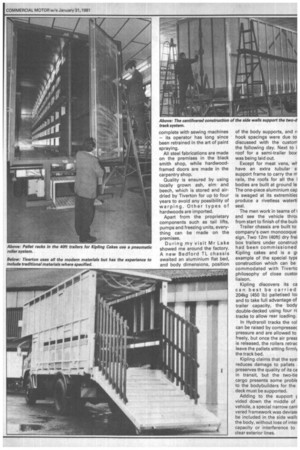

During my visit Mr Lake showed me around the factory. A new Bedford TL chassis awaited an aluminium flat bed, and body dimensions, position

of the body supports, and ri hook spacings were due to discussed with the custorr the following day. Next to i roof for a semi-trailer box' was being laid out.

Except for meat vans, have an extra tubular 5 support frame to carry the rr rails, the roofs for all the I bodies are built at ground le The one-piece aluminium cap is swaged at its extremities produce a rivetless waterti seal.

The men work in teams of and see the vehicle throi from start to finish of the buil( Trailer chassis are built to company's own monocoque sign. Two 12m (40ft) dry frei box trailers under construct had been commissioned Kipling cakes and is a g( example of the special typE construction which can be co mmodated with Tiverto philosophy of close custor liaison.

Kipling discovers its ca can best be carried 204kg (450 lb) palletised bE and to take full advantage of trailer capacity, the body double-decked using four rc tracks to allow rear loading.

In Hydraroll tracks the rol can be raised by compressec pressure and are allowed to freely, but once the air press is released, the rollers retrac leave the pallets sitting firml the track bed.

Kipling claims that the syst reduces damage to pallets preserves the quality of its ca in transit, but the two-tie cargo presents some problE to the bodybuilders for the deck must be supported.

Adding to the support vided down the middle of vehicle, a special narrow cant vered framework was devise( be included in the side wall; the body, without loss of inter capacity or interference to clear exterior lines.