).ADS

Page 51

Page 50

Page 52

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

7 AIR

E. Sherlock-Mesher

" UR jab is to carry loads of air," said Mr. J. C.

Gregory, transport manager of Bristol Aircraft, Ltd. He was explaining to me why it was impossible to quote a figure of annual tonnage moved by the company's fleet and why so often the size of the vehicle and its carrying capacity were totally disproportionate to the load. Components of ..aeroplanes are, of course, designed to the finest limits of weight, and a load 30 ft. long may weigh only a ton or so. The fleet's capacity weight per year is about 125,000 tons. but that bears no relationship to the tonnage moved. • .

Apart from his immediate concern with Bristol Aircraft, Mr, Gregory is responsible for the transport policy of the group, which includes Bristol Aero-Engines, Ltd., and for export shipping and air freight • In addition to controlling a. fleet of literally 101 vehicles: and appliances for figuratively 101 different purposes on the road and in the factory, he finds time to Officiate as chairman of the transport committee of -Bristol Chamber of Commerce and as acting chairman of the western secition of the Institute of Transport.

In supplying the company's transport .he is required to meet four main needs. The first is care, for most aircraft components are extremely expensive and delicate. A deep scratch in a metal component might cause it to be scrapped, because the risk of stress failure developing later is too great to allow doubtful material to be used. Special jigs and stands have been made to ensure the safety of certain of the items transported and to provide for their storage.

In fitting transport into a tightly geared production programme, in which delivery dates are vital, speed and relia

nt 6

bility. are also essential. Flexibility is another important requirement.

"An 'aircraft on ground' signal sets bells ringing and lights flashing," Mr. Gregory told me. With an aeroplane worth flm., the cost of losing a day's operation is subkantial, and the period of grounding through the failure of a component must be reduced to the minimum. The transport system must be such that a new part can be rushed to a disabled aircraft anywhere in the kingdom at a moment's notice.

Obviously, economic; play a part in Bristol Aircraft transport, but in dealing with products of such high value. cheese-paring in the transport department would be inappropriate.

A fair proportion of the work consists of moving secret loads under arrangements laid down by the Ministry of Supply. Strict security regulations are in force and specially constructed containers are used for conveying certain hems. This is, of course, work that only the company's own fleet can undertake.

Substantial use is, however, made of British Road Services and private-enterprise hauliers. It is important that the carriers should understand the traffic and should be well insured. B.R.S. are often employed to haul cased goods, and independent hauliers are selected for suitable traffic.

The fleet is as mixed a medley as I have ever encountered, both in makes and types. It is analysed in an accompanying table, in which it will be seen that Bedford is the predominant make. There are still petrol-engined units in the fleet, but the policy is now to buy oilers.

The miscellany of types comprises 32 vans, six utilities (brakes); four pick-ups; two mobile workshops; six articulated outfits; a special Taskers drawbar trailer, 31 ft. 6 in. long and 8 ft. 6 in. wide; 10 dropsided lorries; two tippers; four mobile cranes; seven tractors; six tenders for fire-fighting and other purposes; three ambulances; eight fork-lift trucks; and 10 other varied models, including even a refuse collector.

A good deal of special bodywork is required, notably for the workshop vans, car transporters, tenders, ambulances, refuellers, civil defence vehicles and so on. The car transporters are used on behalf of an associated company. Bristol Cars, Ltd.

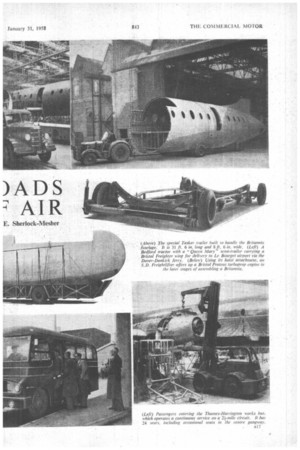

The Taskers trailer was specially designed to carry fuselages. It is extremely low to enable it to pass with its high load into the Britannia assembly hall, which it enters after being turned through 90° on a turntable provided specially for the purpose. It has an extremely long drawbar to permit the fuselage to clear the tractor, on which there are lights and bells to warn the driver when the limit of turn is approaching.

The -vehicles are based mainly at two points on the vast Filton estate—at a central control office in the works and at the Britannia hangar—and at Weston-super-Mare helicopter factory, which was established in August, 1956. One of the tasks of the transport department was to move the helicopter section from Filton to Weston-super-Marc without disturbing production.

Vehicles are allocated to various using departments, which control them and are charged with the cost of the work done, but maintenance is the responsibility of the transport department.

"We transport anything from a bag of rivets to a complete aircraft, or move an entire workshop to other ri I 8 premises," said Mr. Gregory. He also runs an interesting internal bus service with a Thames 4D vehicle with Harrington front-entrance body. It has 24 seats, including occasional tip-up seats in the centre gangway, and its short wheelbase makes it highly manoeuvrable on congested factory roads. As it does not travel on the public road, it does not have to be licensed.

It operates continuously over a 21-mile circuit and in its first year covered 23,529 miles. Originally the service was worked to a time-table, but traffic tended to build up at the published departure times and valuable man-hours were lost through staff stopping work a little earlier than was necessary to be at the head of the queue. Now the circuit is completed every six minutes or so, and with such a frequent service the temptation to leave the bench or desk before time is removed. Shelters are provided at exposed stops.

The goods fleet has two main functions—the collection of components manufactured by sub-contractors and their delivery to the company's works at Filton, Cardiff and Weston-super-Mare, and the delivery of finished products ranging from aircraft to small parts. Overhead travelling cranes load and unload large items at the goods-inwards and dispatch bays. Heavy machinery is dealt with by a 15-ton gantry crane outside the spares organization packing department. Fork trucks and mobile cranes of types listed in the footnote to the table on this page are used at other points in the works.

About 70 per cent. of the vehicles are engaged on work within a 25-mile radius. The greater part of the fleet is employed on regular delivery runs from Filton to the Bristol Aircraft works at Weston-super-Mare and Cardiff; Western Airways, Weston-super-Mare; Douglas, Ltd.. Kingswood, Bristol; Parnalls, Fishponds, Bristol; railheads at Filton Junction, Bristol and Paddington (for collection and distribution in the London area); sub-contractors in the Midlands; airlines at London and Bristol airports; Follands, Ltd., Harnble; Short Bros. and Harland, Ltd., Belfast; stores at Avonmouth and Stapleton Road, Bristol, and sub-contractors in the Bristol area. In addition, interworks and inter-shop transfers have to be performed.

A nucleus of specialized and general-purpose vehicles is retained to supplement those on set runs or to provide for other traffic. The fleet covers about 1m. miles a year, long-distance vehicles averaging 20,000-25.000 miles, and local vehicles 10,000-15,000 miles.

Typical consignments handled naake• a fascinating catalogue. They include complete twin-rotor helicopters, 40 ft. long and 8 ft. 9 in. wide, moved from Filton to Weston-super-Marc. and Sycamore helicopters to London, Liverpool and Avonmouth Docks. Britannia fuselages, jet pipes, Proteus engines and so on are carried to Short Bros. and Harland at Belfast, via the Preston-Fleetwood-Larne ferry. Short Bros. and Harland operate a Britannia production line and there is heavy two-way traffic between Fitton and Belfast. A haulier calls every day at Liverpool Docks to inquire for goods from the Ulster capital consigned to Fitton.

Fins, tailplanes and 50-ft. spar booms are carried by road to Liverpool for shipment to Belfast. Bristol cars, aircraft parts and show equipment have to be taken to the Continent. Bristol Aircraft have been operating a direct road service to the Continent since 1947, via the newerDunkirk train ferry. Both rigid and articulated outfits, including "Queen Marys," are employed. Transport for exhibits to he displayed at shows in Europe and in the United Kingdom has to be carefully scheduled, so that exhibits do not arrive until the stands have been erected.

Drawing Office Moved

A complete drawing office, with a staff of 200, has been moved from Bristol to Weston. Another large task was the transfer of the Sabre repair works from Fitton and the stores at Coalpit Heath to Renfrew. Scotland. In two months, 212 lorry-loadt, including 14 complete Sabre fuselages, were shifted.

When the company's new factory was set up at Cardiff to produce guided weapons, stores and equipment had to be taken from Fitton. and 150 machines of various kinds had to be collected from 14 concerns and Ministry of Supply depots throughout the country. The factory. I may add, was put into operation in three weeks.

As many of the loads are abnormal and indivisible, the company must survey all routes in advance.. A wooden expander is used to measure the heights of overhead wires (allowing for sag), bridges, signs. overhanging trees and so on.

Emphasis on Maintenance Importance is attached-to efficient maintenance. Drivers record defects in duplicate in a book, the top copy going to the maintenance department and the duplicate to the transport manager. All the vehicles are serviced every 1,000 miles, or once a month, whichever is the lesser. On this occasion, the underside of the chassis is carefully inspected. A sticker, showing the mileage at which the next service routine is due. is attached to the vehicle, and it is the driver's responsibility to present it for attention at the appropriate time.

Every thrrd service period, each vehicle is thoroughly examined and tested. Cylinder compressions arc checked by gauge and, if satisfactory, the engine is retuned. All other defects recorded by the tester are corrected.

Vehicles are brought in at 40.000 miles for a special examination with a view to overhaul. Overhauls are performed according to the condition of the vehicle, as revealed by test, and not at a predetermined interval. The exchange-unit system speeds up this work.

A Remington Rand wall chart in the transport mana

ger's office indicates the state of each unit in the fleet. Mileage in thousands appears along the top, with each vehicle listed down the left side. Yellow symbols indicate that 50,000 miles have been Covered, red signifies that a major overhaul is due, black shows the mileage at which a major overhaul was last performed. and blue gives warning that one is overdue.

Vehicle histories are recorded by the Remington Rand Kardex visible-index system. It shows for each unit of the fleet the date and number of each repair job, the work done and the mileage, and costs Of labour and [material. The cards are brought up to date each day. The system is not only neatly efficient, but requires little storage space.

Check on Tools An interesting detail in the tool stores is the use or brass checks. When a man draws a tool, a check bearing his number is placed on the hook from which the item was taken and remains there until the tool is returned.

I was gratified to learn that the Bristol Aircraft transport costing system was based substantially on the recommendations of The Commercial Motor, and that " 'The Commercial Motor' Tables of Operating Costs" had proved to be most helpful. A simple system requiring a Minimum of clerical work is favoured, and to that end 'information is recorded weekly, but costs are worked out over a fourweek period. The management do not require the costs of each vehicle to be calculated to two decimal places, but Mr. Gregory takes detailed samples to ensure that costs

are being kept within reason. •

In the Picture

Although Bristol Aircraft's transport requirements are highly specialized, the company have adopted a principle that could be followed with advantage by many other C-licensees. The transport department is now being brought into the picture at an early stage in the design of a product. Each new design of aircraft tends to create an individual handling problem, and it is vital that efficient transport should be assured from the start. Transport is an afterthought to so many manufacturers that it is refreshing to find one who appreciates its fundamental importance.

[Next week i will deal with the transpOrt system of Bristol Aero-Engines, Ltd.]