For DRIVERS, MECHANICS & FOREMEN.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEX SHILLINGS is awarded each week to the sender of the best letter which we publish on this page ; all others are paid for at the rate of a pinny a line, with an allow:vice for Photographs. All notes afe edited before 68mg published. Mention your employer's name, in confidence, as evidence of good faith, Address, D. 211. and P., " The Commercial Motor," 7-15, Rosebery Avenue, London, E.G. 1.

Lamps Alight—

Light your lamps at 5.23 in London, 5.54 in Edinburgh, 5.18 in Newcastle, 5.29 in Liverpool, 5.27 in Birmingham, 5.33 in Bristol; and 6,10 in Dublin.

Trouble After an Overhaul.

The sender of the following communication has been awarded the 10s. prize this week.

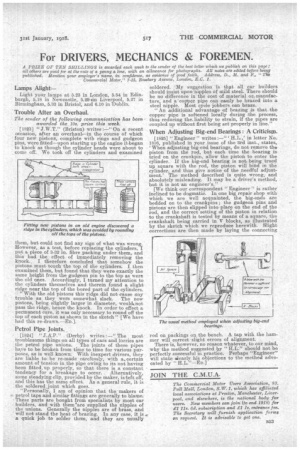

[1823] "J.W.T." (Briston) writes On a recent • occasion, after an overhaulin the course of which • four new pistons, complete with rings and gudgeon pins, were fitted—upon starting up the engine it began " to knock as though the cylinder heads were about to come off. We took off the cylinders and examined them, but could not find any sign of what was wrong. However, as a test, before replacing the cylinders, I put a piece of 3-32 in. fibre packing under them, and this had the effect of immediately removing the knock., I therefore concluded that somehow the pistons, must touch the top of the cylinders. I then examined them, but found that they were exactly the same height from the gudgeon pin to the top as were the old ones. Accordingly, I turned my attention to the cylinders themselves and therein found a slight ridge near the top of the bored part of the cylinders.

"With the old pistons this ridge did not cause any trouble as they were someWhat slack. The new pistons' being slightly larger in diameter, wouldtnot pass the ridge, hence the knock. In order to effect a permanent cure, it was only necessary to round off the

• top of each piston as shown in the sketch" [We have • had this re-drawn.---ED.],

Petrol Pipe Joints.

[1824] " J.A.P." (Derby) writes :—" The most troublesome things on all types of cars and lorries are

the petrol pipe unions. The joints of these pipes , have to be broken from time to time for various pur

poses, as is well known. With inexpert drivers, they are liable -to be re-made careressly, with a.certain amount of tension in the pipe owing to its not having been fitted, up properly, so that there is a constant tendency for a breakage to occur. Alternatively, some steadying clip, provided by the maker, is -left off, and this has the same effect. As a general rule, it is the soldered,joint which goes.

"Personally, I am of opinion that the makers of petrol taps and similar fittings are generally to blame. These parts are bought from specialists by most tar

• builders, and with themiare supplied the nipples of the unions. Generally the nipples are of brass, and " will not stand the heat of brazing. In any case, it is a quick job to solder them, and they are usually

soldered. My suggestion is that all car builders should insist upon nipples of mild steel. There should be no difference in the cost of material or manufacture, and a copper pipe can easily be brazed into a steel nipple. Most cycle jobbers can braze. "An additional advantage of brazing is that the copper pipe is softened locally during the process, thus reducing the liability to strain, if the pipes are coupled up without first being set properly in line."

When Adjusting Big-end Bearings: A Criticism.

[1825] " Engineer " writes :—" EL.,' in letter No. 1816, published in your issue of the 3rd inst., states, 'When adjusting hig-end bearings, do not remove the piston from the rod, but each time the bearing is tried on the crankpin, allow the piston to enter the cylinder. If the big-end bearing is not. being trued up square with the rod, the piston will bind in the cylinder, and thus give notice of the needful adjustment.' The method described is quite wrong, and absolutely misleading. It may be a driver's method, but it is not an engineer's." [We think our correspondent " Engineer " is rather inclined to be dogmatic. In one big repair shop with which we are well acquainted, the big-ends are bedded on to the crankpins ; the gudgeon pins and pistons are then slipped into place on the end of the rod, and the correct setting of the piston in relation to the crankshaft is tested by means of a square, the crankshaft being carried in V blocks, as illustrated by the sketch which we reproduce herewith. Slight corrections are then inacle by laying the connecting rod on packings on the bench. A tap with the hammer will correct slight errors of alignment. There is, however, no reason whatever, to our mind, why the method suggested by " H.L." should not be perfectly successful in practice. Perhaps "Engineer" will state dearly his objections to the method advocated by "