RESILIENCY IN TRUCK WHEELS.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

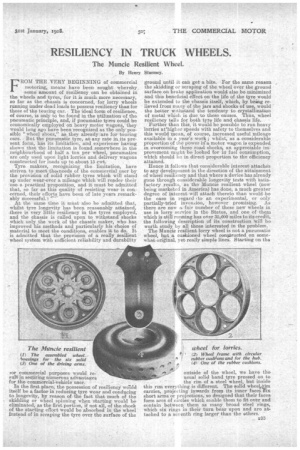

The Muncie Resilient Wheel.

By Henry Sturmey.

F• ROM THE •VERY BEGINNING of commercial motoring, Means have been sought whereby.. some amount of resiliency can be obtained in the wheels and tyres, for it is much more ne-cessary, so far as the chassis is concerned, for lorry wheels running Under dead loads to possess resiliency than for those of the touring car.The ideal form of resilience, of course, is only to be found in -the utilization of the pneumatic principle, and, if prieminitic tyres could be economically employed on heavy motor wagons, they would long ago have been recognized as the only possible " wheel shoes," aethey. alrea:dy are for touring cars. But the pneumatic tyre, at any rate in its present form, has its limitation, and experience ha,ving shown that the limitation is found somewhere in the .neighbourhood of half a ton per wheel, pneumatics are only used upon light lorries and delivery wagons

constructed for loads up to about 15 cwt. .

Tyre makers, recognizing the limitation, have striven to meet theineeds of the commercial user by the provision of solid rubber tyres which will stand up under wear-over a mileage which will render their -useapractical proposition, and it must be admitted that, so far as this quality of resisting wear is con, eerned, their efforts have been of late years remarkably successful.',:.. '"- At the sametime it must also be admitted that, whilst tyre longevity has be-en. reasonably attained, there is very little resiliency in the tyres employed, and the chassis is called upon to withstand shocks which only the work of the chassis maker, who has improved his methods and particularly his choice of material to meet the conditions, enables it to do. It is admitted that the provision of a really resilient wheel system with E a fa dent reliability and durability

ror commercial purposes would result in seOring numerous adVantages for the commercial-vehicle user.

In the first place, the possession of resiliency would itself be a factor in reducing tyre wear and conducing to longevity, by reason of the fact that much of the skidding or wheel spinning when starting would be eliminated, an the first portion, if not all, of the shock of the starting effort would be absorbed in the wheel instead of in scraping the tyre over the surface of the ground until it can geta bite. For the same reason the skidding or scraping of the wheel over the ground surface on brake application would also be minimized a-nd this beneficial effect on the life of the tyre would be extended to the chassis itself; which, by being relieved from many of the jars and Shocks of use, would the better withstand the tendency to crystallization of metal which is due to these causes. Thus, wheel resiliency tells for both tyre life and -chassis life. Furthe/ than this., it would be possible to' run heavy lorrieS at`higher speeds with safety to themselves and thie. would mean, of course, increased useful mileage available in a year's work ; whilst, as a considerable proportion -of the power irf a, motor wagon is expended in overcoming these-road, shocks an appreciable improvement might be looked for in fuel consumption, which should be in direct proportion to the efficiency attained.

Hence it follows that considerable interest attaches to any development in the direction of the attainment of wheel resiliency and that where •a device has already gone through considerable longevity tests with -satisfactory results, as the Muncie resilient wheel (now being marketed in America) has done, a, much greater degree of interest will attachthereto than would be the case in regard ito an experimental,. or only partially-tried invendon, however promising. As there are now a, fair number of these new wheels, in use in lorry service in the States, and one of them which is still running has over 35,000 miles to its credit, the following description of its construction Will ho worth study by all those interested in the problem.

The Muncie resilient lorry wheel is not a pneumatic wheel, but a cushioned wheel con4tructed on somewhat original, yet really simple lines: Starting on the outside of the wheel, we have the usual solid band tyre pressed on to

the rim of a steel wheel, but inside, this rim everything is different. The solid wbeeim carries, projecting inwards from its inner facel, short arms or projections, so designed that their faces form arcs of circles which enable them to fit over and contain between them as many broad steel rings, which six rings in their turn bear upon and are attached to a seventh ring larger than the ethers.

The working hub of the wheel finds a place—a " floating " place—somewhere within the area, enclosed by this seventh ring, and is connected with and drives the wheel by means of six pairs of star arms and six rubber cushions. Inside each of the six rings is placed a solid rubber Lcu.shion formed, not of the usual hard rubber of which the tyres are composed, but of rubber of a comparatively soft and yielding nature, with rubber of harder texture vulcanized on in the centre and outside, where contact is made with • the metal portions of the wheel. The hubs or centres of these rubber cushions are vulca.nized in and are of • malleable iron, through which pins pass, to which the extremities of the six pairs of stararms attach, the other ends of the arms being bolted to the flanges of the hub proper. In the case of the rear wheel, the inner set of six arms is replaced by a solid plate to which is attached the brake drum, It will thus he seen that the weight is carried by' the wheel hub on to the six arms and through them to the rubber cushions and so to the rim, the weight of the car and its load being suspended on the six rubber cushions. All road shocks, impacts and side thrusts are deflected by these cushions from the working parts of the chassis

In actual service, as already said, one set has a record of over 35,000 miles and was still running, whilst it is also claimed that lorries are in service with these wheels which have records of three years use without repair bills or breakage. It is claimed, too' that lorries with these wheels are easier steering aces safer to drive, as side shocks which might throw tho lorry momentarily Out of control are absorbed by the cushion and thereby nullified. .

Moreover, owing to the higher travelling speed permissible, a much larger daily area can be covered.