When you want "custom" bodywork on your trucks there are

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

lots of bolt-on kits which will do the job, discovers Sharon Clancy.

And operators are buying them as well as bodybuilders.

Kit bodies are no longer the poor relation of the bodybuilding world, it seems. Manufacturers say sales are booming and the customer net is widening to include larger trailer and bodybuilders who have traditionally done everything themselves. Shorter lead times and congestion on production lines are forcing some bodybuilders to buy in sub-assemblies or complete kits in order to meet delivery deadlines.

That decision has been made possible by the switch to bolted construction that has swept through the bodybuilding industry in the past three years, especially for curtainsided trailers.

Bolted construction streamlines production by enabling many components to be pre-assembled before being bolted together and then fitted to the chassis. This new production method suits the kit manufacturers who specialise in saving time by building sub-assemblies of tricky items such as rear doors and roofs.

One company that has been exploiting this is curtainsider kit manufacturer Kardel, a division of the Anglesey-based load-handling company Hydraroll. The Kardel kit was developed in Holland by Tasko, a Hydraroll distributor; it has been on sale in the UK for 18 months.

The Kardel kit is an upmarket specification. "Depending on the specification our kit costs around £3,000 to 24,000 and takes eight to 10 hours to assemble," says European sales manager Phil Griffiths. "Bodybuilders save time not price. Those who sell labour too cheaply don't buy our kits." Some bodybuilders buy sub-assemblies while others, such as Al International, buy complete kits. Following the lowering of customer barriers in Europe, trailer rental companies such as Transamerica Trailer Leasing are converting some tilt bodies to curtainsiders, Al reports. Like all kit manufacturers, Kardel offers plenty of options, including three front bulkheads, two rear frames, up to five door types and three roofs. To maximise internal load height within the four-metre height limit, a slim roof and cant rail is needed, supported by two sliding posts each side. All subassemblies have been supplied pre-primed, but from January they will be supplied finish-painted. Kel-Berg Trailer and Trucks started operations in the UK as a trading company, sourcing new and secondhand bodies and trucks in the UK for its parent company in Den mark. After three years turnover had reached 1,000 and it started manufac turing body kits. These are sold in the UK and for export to its Danish parent, Lastas.

Kel-Berg has

ambitious expanOne Kardel option

sion plans. In is radiused front 1998, it sold 200 corner pillars. Euroliner curtain sider trailer kits in the UK, but hopes to more than double that in 1999 by raising production From the current 12 a week to 30. A feature of the Kel-Berg design is the use of clamping plates that are incorporated in bolted joints to reduce fretting and wear around the bolt-holes, especially in the front corners and rear frame. The Euroliner kit with an Edscha sliding roof is the most popular model in the range. It offers a 2.48m width between the rear doors, and 2.7m of height. Galvanised steel is used for the front bulkhead uprights and the rear frame, with aluminium planking for the bulkhead itself and rear doors.

All the sub-assemblies are pre-painted before delivery; fitting is claimed to take less than eight hours. One reason for the fast fitting times achieved by Kardel and Kel-Berg is that once assembled, the body simply bolts on to body mounting plates ready welded to the chassis. Kardel bodies are pre-drilled for bolting to the chassis.

DROPSIDERS

* In an era of greater standardisation, body kits may offer the best chance of customising your body to fulfil your needs rather than those of the vehicle manufacturer or bodybuilder.

However, one area where kit manufacturers have worked closely with chassis manufacturers is in the development of dropsider bodies for chassis-cabs.

Telford-based Ingimex says it developed the first aluminium dropsided body for chassis up to 7.5 tonnes gross back in 1975. More recently it was responsible for the stylish Ford Flareside pickup body. Ingimex's Formula One Special is an attempt to give standard dropsiders the same style. It comprises a galvanised steel underframe, anodised aluminium sides, headboard and tailboard with recessed locks and a one-piece phenolic resin floor. Side raves, pillars and headboard gantry are powdercoated to match the cab colour.

bin The Ingimex Formula One

dropsider has sides painted to dropsider has sides painted to

-A14 ...011■111' match cab colour.

LIGHT VEHICLES

* Kit bodies for lighter vehicles have traditionally required the bodybuilder to do some welding, either of frames or of the body to the chassis. Bolted construction is starting to make inroads, but mainly where construction is all-aluminium. Most kits are sold through smaller bodybuilders, dealers and, at the light end of the market, through chassis-cab manufacturers.

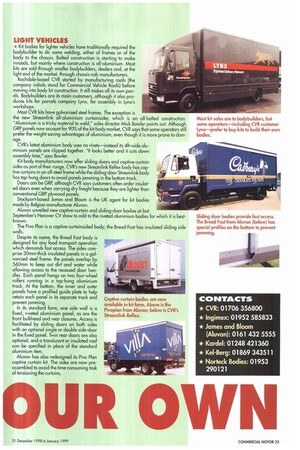

Rochdale-based CVR started by manufacturing roofs (the company initials stand for Commercial Vehicle Roofs) before moving into body kit construction. It still makes all its own panels. Bodybuilders are its main customers, although it also produces kits for parcels company Lynx, for assembly in Lynx's workshops. Most CVR kits have galvanised steel frames. The exception is the new Streamlink all-aluminium curtainsider, which is an all-bolted construction. "Aluminium is a tricky material to weld," sales director Mick Bowler points out. Although GRP panels now account for 90% of the kit-body market, CVR says that some operators still prefer the weight-saving advantages of aluminium, even though it is more prone to damage.

CVR's latest aluminium body uses no rivets—instead its 41t-wide alu minium panels are clipped together. "It looks better and it cuts down assembly time," says Bowler.

sides as part of their range. CVR's new Streamlink Reflex body has cap tive curtains in an all-steel frame while the sliding-door Streamlink body :If' has top-hung doors to avoid panels jamming in the bottom track. Doors can be GRP, although CVR says customers often order insulated doors even when carrying dry freight because they are lighter than conventional GRP plywood panels. Stockport-based James and Bloom is the UK agent for kit bodies made by Belgian manufacturer Aluvan.

Aluvan unveiled new captive-curtain and sliding-door bodies at last September's Hanover CV show to add to the riveted aluminium bodies for which it is bestknown.

The Pivo Plan is a captive-curtainsided body; the Bread-Fast has insulated sliding side walls.

Despite its name, the Bread Fast body is designed for any food transport operation which demands fast access. The sides comprise 30mm-thick insulated panels in a galvanised steel frame: the panels overlap by 560mm to keep out dirt and water while allowing access to the recessed door handles. Each panel hangs on two four-wheel rollers running in a top-hung aluminium track. At the bottom, the inner and outer panels have a profiled guide plate to help retain each panel in its separate track and prevent jamming. In its standard form, one side wall is a fixed, riveted aluminium panel, as are the front bulkhead and rear closures. Access is facilitated by sliding doors on both sides with an optional single or double side-door in the fixed panel. Twin rear doors are also optional, and a translucent or insulated roof can be specified in place of the standard aluminium item.

Aluvan has also redesigned its Pivo Plan captive curtain kit. The sides are now preassembled to avoid the time-consuming task of tensioning the curtains.