A SPEEDY ...VIKING.

Page 28

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Increased Engine Power Gives the Latest '• Volvo Chassis Good All-round Performance: flydrovdc Braking Ensures Safety at High Speeds by John F. Moon,

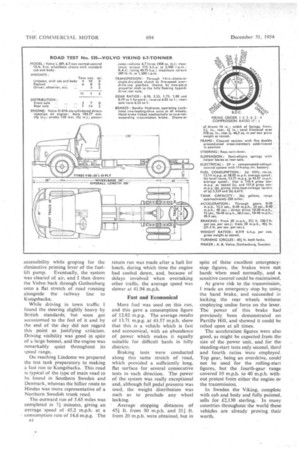

A.M.I.R.T.E. AS a direct descendant of the L 245 series 5-6-ton goods chassis, the Volvo L 389 Viking is more than a worthy successor, being basically the same chassis with a larger engine and greater payload capacity. Its outstanding fuel economy is most marked on highspeed runs, as is evidenced by the high time-load-mileage factor of 7,300 returned after a non-stop run at an average speed of 45.2 m.p.h.

The engine of the L 389 is essentially the original Volvo 100 b.h,p. unit which has been bored out to give an increase of 0.57-litre capacity. In all other respects the chassis remains unchanged, but a more modern bonnet and front-end treatment have improved the external appearance and brought it into line with the L 395 Titan series.

The Volvo D67A six-cylindered direct-injection oil engine develops 115 b.h.p. at 2,400 r.p.m. with a torque output of 289 lb.-ft. at 1,200 r.p.m. In all respects conventional, the engine has a cast-iron monobloc crankcase and cylinder block with replaceable wet-type cylinder liners. Seven steel-backed lead-bronze shell bearings carry the drop-forged crankshaft, similar bearing material also being used in the Connecting rod big-ends.

az The cylinder liners are retained in position by the dual interchangeable cast-iron cylinder heads. Nickel steel is used for the unshrouded inlet valves and the chrome-nickel-alloy steel exhaust valves have Stellitefaced seats.

All valve stems are chromium plated for wear resistance and replacement inserts are fitted in the cylinder heads' .for, all valve seats. Four-hole-type nozzles are located in the cylinder heads centrally above

the bores.

Toroidal combustion chambers are

machined ni the crowns of the aluminium pistons and the efficiency of the -comblistion system was --evidenced durtig the test by the abience of smoke frOm the exhaust :at all 'time's. :A pneumatic governor is used in conjunction with the C.A.V. fuel-injection pump, which is flange-mounted on the left7hand side of the: cylinder block and driven, through an adjustable coupling, from the helical timing gear train. Fuel lift is Provided by a vertical diaphragm pump.

A cushioned centre plate is used With the 14-in.-diameter clutch, which transfers the torque to the five-speed synchromesh gearbox. This box was an overdrive-top unit on the chassis

tested, but a direct-drive-top. box with a low ratio of 7.72 to 1 is available as alternative equipment. The synchromesh engagement is effective On all gears except low ratio and reverse, which have straight-toothed gears.

An ingenious method of reducing idling rattle has been applied to this gearbox. The spigot shaft is a divided component, the clutch splines being linked to the constant-mesh pinion by a small torsion bar. This bar has a torque capacity of 15 lb.-ft. and when the drive is taken up its action is overcome and dog-teeth in the shaft complete the drive.

The engine-gearbox unit has a fivepoint rubber mounting with two

rubber bobbins arranged in an inverted V on each side of the clutch housing. A 12-in.-diameter steel drum with bonded cast-iron lining is bolted to the output flange of the gearbox. for the transmission hand brake, and a two-piece propeller shaft with needle-roller bearings leads the drive to the hypoid gearing of the rear axle.

For test I was provided with a chassis with the high-ratio axle (6.33 to 1), the alternative being a 6.83 to 1 final-drive ratio. An Eaton 18,700 two-speed unit with solenoid change can be supplied to specifi-. cation.

Despite the increased gross-weight allowance, no alteration has been made to the braking system, which has Bendix Hydrovac assistance for the Lockheed two-leading-shoe

hydraulic system. That this is no disadvantage is shown by a comparison of braking distances given by the two vehicles," the maximum retardation of the L 245 being 16:-1 ft. per sec. persec., whilst the L 389 gave a maximum retardation of 21.3 ft. per sec. per sec.

The parallel-width chassis frarne, which has flat side-members behind the cab, is rigidly braced by five , alligator-jawed pressed-steel crossmembers which are cold-riveted to ,the longitudinals A sixth member is bolted in position below the engine bell-housing to relieve the engine of stress at this point. Leftor righthand-drive chassis are manufactured, _ the Swedish standard being for a lef thand driving position.

An Oskarsham composite cab and timber drop-side body were fitted to the test chassis. The cab was large enough to seat three persons in comfort and was well insulated against cold and draughts. The separate driver's seat is fully adjustable and the well-raked steering wheel should assist in. reducing driving fatigue on long journeys.

Iron weights totalling 6 tons 8 cwt. were securely battened into the body for the test payload, and .tbe gross weight was recorded as 11 tons 1 cwt., 3 tons 7 cwt. of this total being imposed upon the front axle. A calibrated test tank with spiritlevels for accurate readings was placed in the cab and, with Mr. K. E. Weiming, of the experimental department, driving, we set off for Partille Hill fOr the giadient and brake-fade trials.. During . During the journey, out of Gothen

burg it was possible to farm a favourable impression of the suspension of the chassis, because most of the road surface out to Partille is cobbled, and is. rough enough to expose anY springing faults. The acceleration in traffic was also , beyond criticisM and the -good steer--; ing lock Made for speedy negotiation , of traffic obstacles.

Secaiktgeae

It was a cold; wet day, and the _ ambient temperature at the bottom ofthe hill was 39° F. With the lower half of the pressurized radiator stack blanked off, the coolant ternperature was found to be 156° F., and after a brisk *minute climb, of which 3 minutes were spent-in second gear, the top-tank temperature" had risen by only 8° F.

The hill, which has a general gradient of 1 in 13, has several Sections of. 1-in-10 severity, and it was on and between these s.ections that the use of second gear became necessary. The engine was not overworked, however, and with a lower gear available and ample power in hand, a 1-in-4 gradient should be well within the capabilities of this vehicle.

I drove the L 389 down the -1-mile hill using the foot brake to restrict the speed to. about 15 m.p.h. At the bottom of the hill there was smoke issuing from all drums, but the braking efficiency was but little impaired and there was only a slight increase in pedal travel.

Suspension Test After passing through Landvetter, a start was made on the fuelconsumption trials, but with less than a mile covered we encountered a full-scale road-reconstruction area which, although providing .a perfect test for suspension and general roadholding, would have been of little assistance in obtaining a reliable fuel-consumption figure. Once on a reasonable road surface again, a restart was made along the hilly route out to Hindas.

The return mileage totalled 14.2, and, at an average speed of 38.05 m.p.h., 1..075 gallons of fuel were used, giving a consumption rate of 13.14 m.p.g. Overdrive top was used wherever possible, but traffic conditions made the use of third gear necessary on several occasions.

After these first consumption tests a maladjusted fuel tap caused the fuel system to become emptied, and I was grateful for the good engine accessibility while groping for the diminutive priming lever of the fuellift pump. Eventually, the system was cleared of air, and I then drove the Volvo back through Gothenburg onto a flat stretch of road running alongside the railway line to Kungsbacka.

While driving in town traffic I found the steering slightly heavy by British standards, but soon got accustomed to the feet of it and by the end of the day did not regard this point as justifying criticism. Driving visibility was good in spite of a large bonnet, and the engine was remarkably quiet throughout its !peed range.

On reaching Lindome we prepared the test tank preparatory to making a fast run to Kungsbacka. This road is typical of the type of main road to be found in Southern Sweden and Denmark, whereas the hillier route to Hindas was more representative of a Northern Swedish trunk road.

The outward run of 5.65 miles wascompleted in 71 minutes, giving an average speed of 45.2 m.p.h. at a consumption rate of 14.6 m.p.g. The

a4 return run was made after a halt for lunch, during which time the engine had cooled down, and, because of delays involved when overtaking other traffic, the average speed was slower at 41.94 m.p.h.

Fast and Economical

More fuel was used on this run, and this gave a consumption figure of 12.82 m.p.g. The average results of 13.71 m.p.g. at 43.57 m.p.h. show that this is a vehicle which is fast and economical, with an abundance of power which makes it equally suitable for difficult hauls in hilly districts.

Braking tests were conducted along this smile stretch of road, which provided a sufficiently long, flat surface for several consecutive tests in each direction. The power of the system was really exceptional and, although full pedal pressure was used, the weight distribution was such as to preclude any wheel locking.

Average stopping distances of 451 ft. from 30 m.p.h. and 211 ft. from 20 m.p.h. were obtained, but in

spite of these excellent emergencystop figures, the brakes were not harsh when used normally, and a sensitive control could be maintained.

At grave risk to the transmission, I made an emergency stop by using the hand brake, and succeeded in locking the rear wheels without employing undue force on the lever. The power of this brake had previously been demonstrated on Partille Hill, and showed it could be relied upon at all times.

The acceleration figures were also good, as might be expected from the size of the power unit, and for the standing-start tests only second, third and fourth ratios Were employed. Top gear, being an overdrive, could not be used for the rolling-start figures, but the fourth-gear range covered 10 m.p.h. to 40 m.p.h. without protest from either the engine or the transmission.

In Sweden the Viking, complete with cab and body and fully painted, sells for £2,130 sterling.. In many countries throughout the world these vehicles are already proving their worth.