Patents Completed.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

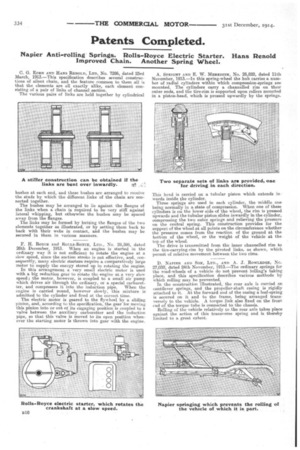

Napier Anti-rolling Springs. Rolls-Royce Electric Starter. Improved Chain. Another Spring Wheel.

C. Gr. EDEN AND HANS RENOLD, LTD, No. 7286, dated 23rd March, 1913.—This specification describes several constructions of silent chain, and the feature common to them all is that the elements are all exactly alike, each element consisting of a pair of links of channel section.

The various pairs of links are held together by cylindrical bushes at each end, and these bushes are arranged to receive the studs by which the different links of the chain are connected together.

The bushes may be arranged to lie against the flanges of the links when a chain is required to be very stiff against lateral whipping, but otherwise the bushes may be spaced away from the flanges, The links may be formed by butting the flanges of the two elements together as illustrated, or by setting them back to back with their webs in contact, and the bushes may he secured in them in various manners.

F. H. ROYCE and Ror,Ls-RoYen, LTD.: NO. 29,398, dated 20th December, 1913. When an engine is started in the ordinary way it is not sufficient to rotate the engine at a slow speed, since the auction stroke is not effective, and, consequently, many electric starters require a comparatively large motor to supply the energy stored up in rotating the engine.

In this arrangement a very small electric motor is used with a big reduction gear to rotate the engine at a very slow speed; the motor, however, is coupled to a small air pump which drives air through the ordinary, or a special carburetter, and compresses it into the induction pipe. When the engine is carried round, however slowly, this mixture is admitted to the cylinder and fired at the correct time. The electric motor is geared to the flywheel by a sliding pinion, and, according to the specification, the gear for moving this pinion into or out of its engaging position is coupled to a valve between the auxiliary carburetter and the induction pipe, so that this valve is moved to its open position whenever the starting motor is thrown into gear with theengine. A. SPEIGHT AND E. W. MEREDITH, No. 25,828, dated 11th November, 1913.—In this spring-wheel the hub carries a number of radial cylinders within which compression-springs are mounted. The cylinders carry a channelled rim on their outer ends, and the tire-rim is supported upon rollers mounted in a piston-head, which is pressed upwardly by the springs.

This head is carried on a tubular piston which extends inwards inside the cylinder.

Three springs are used in each cylinder, the middle one being normally in a state of compression. When one of these cylinders is on the lower aide of the wheel, the rim is pressed upwards and the tubular piston slides inwardly in the cylinder, compressing the two outer springs and relieving the pressure on the central spring. This construction provides for the support of the wheel at all points on the circumference whether the pressure comes from the reaction of the ground at the bottom of the wheel, or the weight of the vehicle at the top of the wheel.

The drive is transmitted from the inner channelled rim to the tire-carrying-rim by the pivoted links, as shown, which permit of relative movement between the two rims.

D. NAPIER. AND SON, LTD., AND A. J. ROWLEDGE, No. 27,032, dated 24th November, 1913.—The ordinary springs for the road-wheels of a vehicle do not prevent iolling's taking place, and this specification describes various methods by which rolling may be prevented.

In the construction illustrated, the rear axle is carried oil cantilever springs, and the propeller-shaft easing is rigidly attached to it. At the forward end of the easing a leaf-spring is secured on it and to the frame, being arranged transversely to the vehicle. A torque link also fixed on the front end of the torque tube is connected to the chassis.

Rolling of the vehicle relatively to the rear axle takes place against the action of this transverse spring and is thereby limited to a great extent.