EDI R Drivers &Mechanics

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best corn. munication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Light Up Your Lamps At 1.58 on Thursday ; 4.58 on Friday ; 5.0 on Saturday; 5.2 on Monday ; 5.3 on Tuesday ; 5.5 on Wednesday.

Milling and Slotting Attachment for a Lathe.

The sender of the following communication has been awarded the 10s. prize this week.

[1579] J.M.A.Y. (Walthamstow) writes :—" The following attachment may be of interest to my fellow readers. By its use, a screw-cutting lathe may be readily used either as a milling machine or as a Blotter. It is invaluable in the small garage for cutting keyways or small gearwheels.

Referring to the sketch [Which we have had redrawn.—En.] it shows a, mandrel held between lathe centres. One end of this is screwed to a size determined by the job, the other is turned a driving fit for the screw-cutting change wheel belonging to the lathe, and a key is fitted.

"Assuming that we wish to cut an eight-tooth wheel, select any one of the change wheels with number of teeth divisible by eight (such as 40, 80, 120), and force it on the mandrel. The blank to be cut is now secured on the mandrel. A stop must next be fitted on to the lathe face-plate to rest securely and snugly in teeth of change wheel. Now tighten main bearings of lathe so that face-plate cannot move, and tighten back centre.

"Remove belt from lathe cone and fix a pulley on spindle of change-gear quadrant, driving this by the main lathe belt. By this means we get the power to mechanically operate the saddle, and as will be readily seen a large ratio of feeds can be obtained.

"The tool, shaped exactly as tooth space to be out, is next placed at dead centres in the lathe, and all is ready.

"When the first tooth is cut to depth, return the stop, and, without moving face-plate, give the change wheel one-eighth of a turn, replace stop, and proceed with the next tooth." Testing Repaired Radiators.

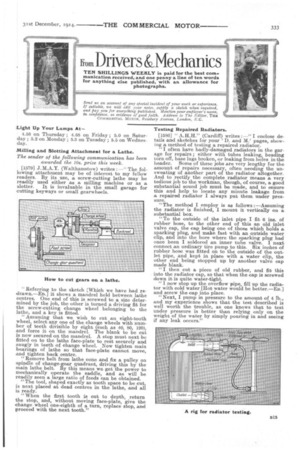

[1580] " A.H.H." (Cardiff) writes :—" I enclose details and sketches for your D. and M.' pages, showing a method of testing a repaired radiator. I often have badly-damaged radiators in the garage for repairs ; either with tubes leaking, beading torn off, base lugs broken, or leaking from holes in the header. Some of these jobs are very lengthy for the amount of repairs necessary, often needing the unsweating of another part of the radiator altogether. And to rectifythe complete radiator means a very tedious job to the workman, though, of course a good substantial sound job must be made, and tA-; ensure this and help to locate any minute leakage from a repaired radiator I always put them under pressure.

"The method I employ is as follows :—Assuming the radiator is finished, I mount it vertically on a substantial box.

"To the outside of the inlet pipe I fit 6 ins, of rubber hose to the other end of this an old inlet valve cap, die cap being one of those which holds a sparking plug, and make fast with an. outside water clip, and into the bore where the sparking plug had once been I soldered an inner tube valve. I next connect an ordinary tire pump to this. Six inches of rubber hose was fitted on to the outside of the outlet pipe, and kept in place with a water clip, the other end being stopped up by another valve cap made blank.

"I then cut a piece of old rubber, and fit this

• into the radiator cap, so that when the cap is screwed down it is quite water-tight. "1 now stop up the overflow pipe, fill up the radiator with cold water [Hot water would be better.—En.] and screw the cap into place.

"Next, I pump in pressure to the amount of 4 i lb., and my experience shows that the test described well worth the trouble, as one knows that to test under pressure is better than relying only on the weight of the water by simply pouring in and seeing if any leak occurs."