DUTCH EH El

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

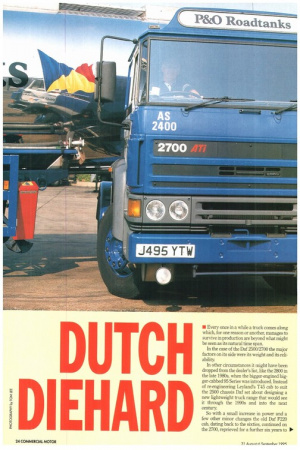

• Every once in a while a truck comes along which, for one reason or another, manages to survive in production are beyond what might be seen as its natural time span.

In the case of the Daf 2500/2700 the major factors on its side were its weight and its reliability.

In other circumstances it might have been dropped from the dealer's list, like the 2800 in the late 1980s, when the bigger-engined bigger-cabbed 95 Series was introduced. Instead of re-engineering Leyland's 145 cab to suit the 2500 chassis Daf set about designing a new lightweight truck range that would see it through the 1990s and into the next century.

So with a small increase in power and a few other minor changes the old Daf F220 cab, dating back to the sixties, continued on the 2700, reprieved for a further six years to 1110. In 1990 the FT2700HS set a new fuel economy record, returning 351it/100km (8.07mpg) at 32.5 tonnes, just slightly better than we achieved with the Ford Cargo 3224. Just as significant was its average speed of 70.47km/h (43.8mph), giving journey times more in line with more powerful 38-tonners of the day. Unladen weight was one of the 2700's strongest features—complete with a full air deflector kit the unit weighed in at just 6,005kg

On the level the 2700 would invariably pull away in 2H, skipping to 4H, then 5H and 6H before resorting to use of the splitter Splitting at 1,750rprn dropped the engine speed to about 1,500rpm, at the top end of maximum torque, so the entire day could be spent running in the green band, regardless of the terrain. At motorway speeds it trundled along at about 2,000rpm and we climbed Shap making just one split down the box to 8L.

There were few complaints on driveability but our ZF Ecosplit gearbox was notchy and shift loads were heavy, especially when moving off from cold. Despite riding on a 3.25m wheelbase with an air sus

pended drive axle, the ride became just a little too lively over the roughest section of the route, but cab roll was less than with many taller tractive units. Visibility from the driver's seat was fairly good, if it was not set too high when the header rail started to intrude. However, the clutch pedal was too high and the angle of the accelerator made it difficult to lift off completely when changing gear The 95-style light and dark grey trim was a vast improvement on the 2500's sombre brown. There was an enormous amount of storage under the bunk but that was little consolation if driving a day cab model where there was precious little Despite the old cab almost all of the competitive models in the class cost less, with the exception of Iveco Ford and Scania.

The 8.25-litre engine in turbocharged form dates from the FT2000 which was first imported in 1973 with a sixspeed constant-mesh splitter box on a 3.25m wheelbase rated for operation at 38 tonnes. It was followed by the FT2200 in 1977 and the slightly more powerful FT2300 with a ninespeed constant-mesh range-change box.

Charge-cooling increased the power to 244hp in the FT2500 which, with a 12-speed box, replaced the 2300 in 1982 with models available for 28 and 32.5 as well as 38 tonnes. Although Daf had an opportunity to use Leyland Dais T45 cab (and it had already introduced the 95 Series cab by 1990) Daf continued to use day and sleeper versions of the traditional flat panelled steel cab on the FT2700. It came as standard along with automatic slack adjusters and an air dryer.

Basic specification included a ZF 16-speed synchromesh box and the 95 Series' single reduction axle in place of the hub-reduction axle: ECAS drive axle air suspension was offered as an option for the first time on a medium-weight tractive unit A reworked block with larger exhaust ports, new heads and a more efficient turbocharger in part accounted for the extra power output over the FT2500. The 2700 tractor—on 2.95,325 and 3.65m wheelbases—continued in pro duction until June 1993. A small increase in capacity uprated the small six-cylinder engine to 8.65 litres for the F1'75 series, which has taken over the role of light tractive unit in the Daf range with outputs of 240,270 and 300hp.

OPERATORS

David Lowe is fleet engineer for a major food distribution company in the South-West. He runs the group's main workshops which look after 34 trucks including Renaults, MANs, Fodens, Leyland Dafs and 15 Daf 2500s. The trucks operate on long-haul distribution averaging 1,000 miles at 31 tonnes GCW "Restricted to 56 miles an hour the 2500s are not powerful enough for today's operation," says Lowe. "Future policy will be to change after five years and reduce maintenance costs." He can service three Leyland Daf 75s in the time it takes to look after one of the 2500s, which are up to 10 years old—some of them have been round the clock.

"The 825-litre engine is quite economical averaging about 8.5mpg throughout the fleet," he says, "but with wear it is inclined to blow oil out of the breather. Using a modified filter from a 2800 restricts the oil from spraying all over the block and on to the road, but is usually ready for a rebuild after 250,0001cm. This takes 40 hours to do and the parts—pistons, liners, big ends, mains, cam followers, guides and gaskets—cost a little over £1,500. A short engine costs about £4,000 and doesn't save much in the way of time." Multipart parts are less expensive than Dafs own, he adds.

Some of the water problems can be prevented if the centre water way between block and head is blanked off. Lowe says that in all the years he has run the 2500s he has only had to replace one gearbox and one drive axle. The clutch is air assisted and is easily ridden so clutch life depends on the driver.

Although hard brake linings caused excessive drum wear on earlier 2300s this problem was not transferred to the later 2500 and 2700 versions. The NSF tyre tends to feather at the outer edge of the tread. A mod to the axle costing about £200 can stop it but was probably only worth considering when the vehicle was new. The cab is solidly built and wax treatment prevents it rusting from the inside. However, rust seen on older cabs does attack the outer surfaces in the seams and around the windows where the rubbers rot and hold water—Multipart can supply a replacement panel for the top of the screen Inside the trim stands up as well as any but older models may suffer worn seat slides.

"The 2500s were OK from new but they are not a truck to buy secondhand," Lowe says."They need too much time spent on them.

Joe Chapman, managing director of P and 0 Tanks, operates 105 vehicles from Stanford le-Hope, Essex. Apart from one Mercedes and half a dozen ERFs the fleet is predominantly Leyland Daf and about 30% are 2700s. They deliver petroleum products to resale sites in the South of England. "We bought the 2700s to replace the earlier 2800s which had the 11.6-litre engine. The 2700 was lighter, just as manoeuvrable and purported to be capable of the same work load without loss in economy," Chapman says.

"We were getting between 7,5 and 8.0mpg at the time. The oldest is on a G-plate. Some are double shifted and have covered more than 500,000 miles now," he says." We normally keep them for six or seven years so they are coming up for renewal. I imagine we will replace them with the Leyland Daf 75.300 which we believe will give enough power for our purposes. We have a list of dealers who usually bid on them or we dispose of the through smaller interested hauliers," he says.

"They have been a very good workhorse but are beginning to suffer now, But after 600,000 to 700,000 you would expect that," says Chapman.

P and 0 refurbishes some of the fleet every two years but Chapman says even the vehi cles that have not been repainted are show ing no signs of rust. "Many manage to go their whole life without major overhauls," he says. "I don't think the 2700 has a high resid ual value but it reflects the price we paid for them when they were new. You might get more for a Scania but it would have cost more to begin with. We get more or less what we expect for them.

"The back-up is excellent," he adds. "If we do have a problem then the local dealer moves heaven and earth to solve it. We tend to use Daf parts. As we carry an imprest stock we get a good deal. The 2700 has high driver acceptance and the price is right at the time we buy them. We find them very reliable. I don't think we experience breakdowns any more than anyone else does with other makes."

Conoco left London three years ago and moved its headquarters to the heart of the English coun tryside at Warwick. Dave Tansley, team leader of its transport engineering department, is responsible for the specification of the company's mad-going fleet of 120 trucks.

A mix of Leyland Daf, ERF and Volvo tractive units operate out of depots located around the country, with 30,000 and 34,000litre tank trailers carrying petroleum products. Out of 10 DAF 2700s three run at 38 tonnes using stainless steel tanks carrying aviation fuel. The other seven run at 32.5 tonnes but also on five axles.

"The 2500 proved to be a very flexible vehicle and we moved up to the 2700 when it became available in 1990," says Tansley. "It's got good visibility, it's quiet and the 16-speed transmission with single-reduction axle gives flexibility. They cover between 80,000 and 100,000km a year and have proved successful at 38 tonnes. Over a 300-mile round trip with quite flat terrain they return 9.85mpg.

"The 32.5-tonners are used on distribution work and give us 8.6mpg." he adds. "We plan to keep them for six years or 800,000km so we haven't re-placed any yet. We use ADT to sell most of our tucks at auction where they make our price. A seven-year-old Daf 2500 with day cab recently fetched £5,000," he says. "Because we operate to 8S5750 we only use Daf warranted parts or identical propri etary branded parts. Understandably they cost more than pattern parts but maintenance costs work out at 3p/km for the 2700 which is comparable with other vehicles in the fleet.

"Nationally we have a brilliant relationship with Leyland Daf. We have quarterly meetings and any warranty problems are settled on the spot. Locally some dealers are better than others," he says. "The 2700 has been quite reliable. Tanks put a lot of strain around the fifth wheel but the chassis is pretty strong. We haven't suffered much of the usual cracking. The ABS electrics were a problem for a while. Water was getting into the loom through a plug at the front of the chassis. Tyre wear is not a problem for us. Across the fleet we pay 2.1p/km. We don't suffer unduly with rust. The cabs are wax treated when new and our vehicles are repainted twice during their seven year life and they are washed professionally on a regular basis.

Our image is important to us," says Tansley. "Our drivers like the 2700 and whole life costings show us it is a very economical truck to operate. When the time comes we will probably move up to 300hp with the Leyland Daf 75 series which we already run at 32.5,35 and 38 tonnes."

Eighteen months ago non-franchise dealer AR Pugh Commercials moved from one of the largest commercial vehicle sites on the Old Kent Road, London, to a two-acre site on the A20 at Addington in Kent. The company usually keeps a stock of about 60 trucks of most makes from 7.5 tonnes upwards.

We asked managing director Alan Pugh about the availability of the Daf 2700. "We see them about," he says. "I have a 2500 which is the earlier version but! don't have a 2700 in stock at the moment. They are not particularly good sellers and the price reflects that. We would expect to sell a good clean one on a G-plate with air suspension and full air kit for around £14,500. A similarly powered Mercedes-Benz 1726 tractive unit would fetch another L5,000."

"The 2700's engine suffers from a reputation for overheating and even with a fiveyear-old model you can expect to see a little rust on the cab," he adds. "Some of the larger operators are still running 85/86 models but they are not worth a lot at that age—perhaps £6,000. The few we do sell usually go to owner-drivers who are attracted by the price."

Main dealer Harris Commercial, located at West Thurrock, Essex, just off junction 31 on the M25, carries £300,000 worth of used stock from parts for LDV vans to the 95 Series tractive units. Sales director Frank Parr says: "We had a lot of succpss in selling new 2700s to the oil companies in this area and in particular to customers who were interested in a low unladen weight. More often than not they opted for day cab-models.

"They are still operating them, which says quite a bit about the vehicle, but we haven't taken any back in part exchange," he says. "In the used truck market there is not much demand for them in this area. Apart from the oil companies most of our customers are involved in container or continental haulage and in the secondhand market they tend to go for the big horse power, big cab vehicle. They might be more appealing to an ownerdriver with a distribution type operation. The usual replacement for the 2700 would be the 75 Series which has a modern styled cab and the option of a bit more power."

The Daf 2700 tractive unit looks dated but is light and gives a good fuel return at 32.5 tonnes and even at 38 tonnes where the going is not too tough. It has a sound drive line and strong chassis and it is backed by strong dealer network. The 8.25-litre power unit has a reputation as a wet engine and may need rebuilding more often than the larger Daf engines. Originally mostly bought by the larger fleets they don't appear on the used truck market much before six or seven years old and will incur higher maintenance costs than newer models. However, for a small own-account operator running below 38 tonnes the 2700 could well deliver the goods.