SUSPENSION SYSTEMS: H(

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

CAN THEY BE IMPROVED?

Shortcomings of the. Orthodox Leaf Spring dent Wheel Mountings. Hydraulic Damp

;cussed. Self-adjusting Springs. IndepenI and Some Promising Pneumatic Systems.

connections are particularly susceptible to vibration, as are also the riveted joints of frame members, and those who had experience with mechanical road transport during tile war will not need to be reminded of the rapidity with which a chassis will break up under the hammering which results from rough roads and inade quate springs.

It seems also worth mentioning that the suspension syst e In should have the effect of keeping the wheels on the road. Many lorries to-day, if run with only a light load, show a propensity to wheel bounce, which leads to inefficient traction and braking, together with unduly rapid 'tyre wear.

This brings us to one of the most glaring defects of springs of the leaf type, namely, that they are not commonly made adaptable to loads of different weights. The problem is particularly acute in goods-carrying lorries; for example, the springs may be called upon to carry a gross weight of four tons on one journey and eight tons on the next. In order to safeguard the springs against fracture, the makers design them to carry the maximum permissible load, which means that they are much too stiff and rigid to provide reasonable shock insulation when the vehicle is driven unladen or only partly laden.

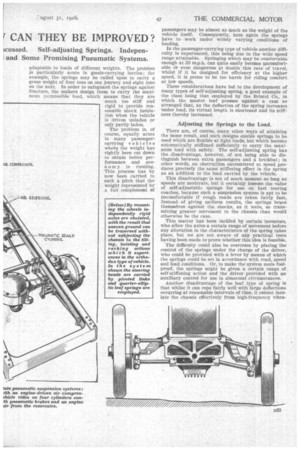

The problem is, of course, equally acute in many passengercarrying vehicles where the weight has rightly been cut down to obtain better performance and economy in running. This process has by now been carried to such a pitch that the weight represented by a full complement of

passengers may be almost as much as the weight of the vehicle itself. Consequently, here again the springs have to work under widely varying conditions of loading.

In the passenger-carrying type of vehicle another difficulty is experienced, this being due to the wide speed range attainable. Springing which may be comfortable enough at 20 m.p.h. can quite easily become uncomfortable or even dangerous at double this rate of travel, whilst if it be designed for efficiency at the higher speed, it is prone to be too harsh for riding comfort at low speeds.

These considerations have led to the development of many types of self-adjusting spring, a good example of the class being that employed by the Bristol Co., in which the master leaf presses against a cam so arranged that, as the deflection of the spring increases under load, its virtual length is shortened and its stiffness thereby increased.

Adjusting the Springs to the Load.

There are, of course, many other ways of attaining the same result, and such designs enable springs to be used which are flexible at light loads, but which become automatically stiffened sufficiently to carry the maximum load with safety. The self-adjusting spring has the disadvantage, however, of not being able to distinguish between extra passengers and a brickbat ; in other words, an obstruction encountered at speed produces precisely the same" stiffening effect in the spring as an addition to the load carried by the vehicle.

This disadvantage is not of much moment so long as speeds are moderate, but it certainly lessons the value of self-adjustable springs for use on fast touring coaches, because such a suspension system is apt to be uncomfortable if rough roads are taken fairly fast. Instead of giving uniform results, the springs brace themselves against the shocks, as it were, so transmitting greater movement to the chassis than would otherwise be the case.

This matter has been tackled by certain inventors, who allow the axles a certain range of movement before any alteration in the characteristics of the spring takes place, but we are not aware of any practical tests having been made to prove whether this idea is feasible.

The difficulty could also be overcome by placing the control of the springs under the charge of the driver. who could be provided with a lever by means of which the springs could be set in accordance with road, speed and load conditions. Or, to make the system more foolproof, the springs might be given a certain range of . self-stiffening action and the driver provided with an auxiliary control for use in abnormal circumstances.

Another disadvantage of the leaf type of spring is that whilst it can cope fairly well with large deflections occurring at reasonable intervals of time, it cannot insulate the chassis effectively from high-frequency vibra

tions of low amplitude, which produce discomfort and tend to loosen screwed parts. Several schemes have been devised to deal with such vibrations, amongst which may be mentioned fabric shackles, flexible bushings for shackle pins, the housing of the ends of the top leaf between rubber blocks and the supersession of shackles by pneumatic cylinders or coil springs. Some of these systems are becoming quite widely used for private cars and are worth the attention of commercial vehicle makers.

'It seems opportune here to mention the pneumatic tyre, which has proved such an outstanding success for passenger-carrying vehicles during the past few years. Such a tyre does, of course, safeguard the chassis and the load, whilst improving riding comfort to a marked degree. On the other hand, it cannot be said, in itself, to solve the suspension problem. It is, indeed, a fact that in many instances faults such as rolling and bouncing become more pronounced when pneumatic tyres are employed. Shock absorbers, such as are fitted to so many private ears, have, of course, a controlling effect tending to damp out undesirable movements, but they represent extra parts requiring attention, which should be avoided if the suspension system can be made efficient without them.

There is also the matter of insulation between the chassis and the body to consider, such as the leafspring system of Strachan and Brown and the Holden system, in which latter an inflated tube fits between channels carried by the body and the chassis. Such devices, whilst effective in safeguarding the bodywork, have, of course, no safeguarding effect upon the chassis.

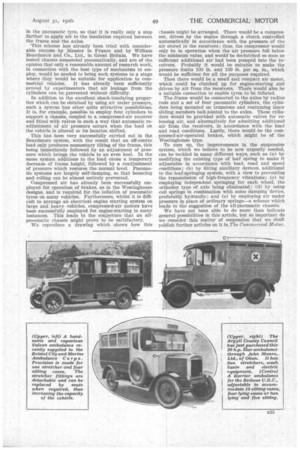

Criticism without constructive suggestions is not of much value, so let us turn to a consideration of some methods of suspension which might well prove superior to current types. Of these, one of the most promising ideas is to spring each wheel independently of the others. The absence of rigid axles produces some difficulties in construction, but that these difficulties can be overcome has been fully proved by experimental chassis which have been built from time to time on this system.

In the orthodox vehicle, shocks and movements applied to one wheel of each pair are transmitted to the other wheel through the axles, and any tilting of the axles is bound to result in a certain amount of conclusively shown that very comfortable riding and excellent road holding are characteristics of such springing. The road-holding propensity is, no doubt, largely due to the fact that unsprung weight is reduced to a minimum, so that the wheels do not tend to bounce for prolonged periods after meeting obstructions.

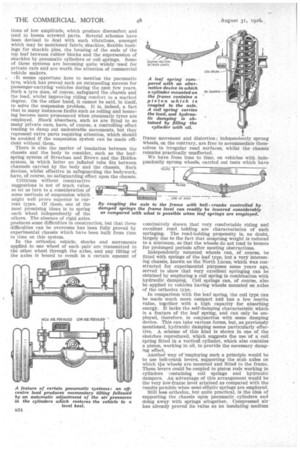

Independently mounted wheels can, of course, be fitted with springs of the leaf type, but a very interesting chassis, known as the North Lucas, which was constructed for experimental purposes some years ago, served to show that very excellent springing can be obtained by employing a coil spring in combination with hydraulic damping, Coil springs can, of course, also be applied to vehicles having wheels mounted on axles of the orthodox type.

In comparison with the leaf spring, the coil type can be made much more compact and has a low inertia value, together with a high capacity for absorbing energy. It lacks the self-damping characteristic which is a feature of the leaf spring, and can only be employed, therefore, in conjunction with some damping device. This can take various forms, but, as previously mentioned, hydraulic damping seems particularly effective. A scheme of this kind is shown in one of the sketches reproduced, which suggests the use of a coil spring fitted in a vertical cylinder, which also contains a piston, working in oil, to provide the necessary damping effect,

Another way of 'employing such a principle would be to use bell-crank levers, supporting the stub axles on which tt,e wheels are mounted and fitted to the frame. These levers could -be coupled to piston rods working in cylinders containing coil springs and hydraulic dampers. An advantage of this arrangement would be the very low-frame level attained as compared with the results possible when semi-elliptic springs are employed.

Still less orthodox, hut quite practical, is the idea of supporting the chassis upon pneumatic cylinders and doing away with springs altogether. Compressed air has already proved its value as an insulating medium in the pneumatic tyre, so that it is really only a step farther to apply air to the insulation required between the frame and the axles.

This scheme has already been tried with considerable success by Messier in France and by William Beardmore and Co., Ltd., in Great Britain. We have tested chassis suspended pneumatically, and are of the opinion that only a reasonable amount of research work, in connection with the best type of niechaeism to employ, would be needed to bring such systems to a stage where they would be suitable for application to commercial vehicles. It has already been sufficiently proved by experimenters that air leakage from the cylinders can be prevented without difficulty.

In addition to the excellent shock-insulating properties which can be obtained by using air under pressure, such a system has other quite attractive possibilities. It is, for example, possible to employ four cylinders to support a chassis, coupled to a compressed-air receiver and fitted with valves in such a way that automatic readjustment of air pressure occurs when the load on the vehicle is altered or its location shifted.

This has been very successfully carried out in the Beardmore system, with the result that an off-centre load only produces momentary tilting of the frame, this being immediately followed by an adjustment of pressure which brings the vehicle to an even Reel. In the same system additions to the load cause a temporary decrease of frame height, followed by a readjustment of pressure which restores the normal level. Pneumatic systems are largely self-damping, so that bouncing and rolling can be almost entirely prevented.

Compressed air has already been successfully employed for operation of brakes, as in the Westinghouse designs, and is required for the inflation of pneumatic tyres on many vehicles. Furthermore, whilst it is difficult to arrange an electrical engine starting system on large and heavy vehicles, compressed-air motors have been successfully employed for engine-starting in many instances. This leads to the conjecture that an allpneumatic chassis might prove to be satisfactory.

We reproduce a drawing which shows how this

chassis might be arranged. There would be a compressor, driven by the engine through a clutch controlled automatically in accordance with the pressure of the air stored in the reeervers; thus, the compressor would only be in operation when the air pressure fell below the minimum value, and would be declutched so soon as sufficient additional air had been pumped into the receivers. Probably it would be suitable to make the pressure limits 100 lb. and 105 lb. per sq. in., which would be sufficient fiOr all the purposes required.

Then there would be a small and compact air motor, which could by clutched up for engine-starting and driven by air from the receivers. There would also be a suitable connection to enable tyres to be inflated.

The frame would be connected to the axles by radius rods and a set of four pneumatic cylinders, the cylinders being mounted on trunnions and containing inner sliding members ball-jointed to the axles. These cylinders would be provided with automatic valves for releasing air, and alternatively for admitting additional air from the receivers, in accordance with the load and road conditions. Lastly, there would be the compressed-air-operated brakes, which might be of the Westinghouse type.

To sum up, the improvements in the suspension system, which we believe to be now urgently needed, can be tackled in many different ways, such as (a) by modifying the existing type of leaf spring to make it adjustable in accordance with load, road and speed conditions ; (b) by fitting auxiliary devices, additional to the leaf-springing system, with a view to preventing the transmission of high-frequency vibrations: (C) by employing independent springing for each wheel, the orthodox type of axle being eliminated; (d) by using coil springs in combination with some damping device, preferably hydraulic; and (e) by employing air under pressure in place of ordinary springs—a scheme which leads to the suggestion of the all-pneumatic chassis.

We have not been able to do more than indicate general possibilities in this article, but so important do we consider this matter of suspension that we shall publish further articles on it in The Commercial Motor.