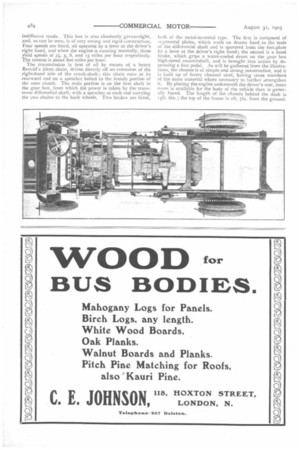

The Latest Wolseley Motor Omnibus.

Page 18

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

We give side and plan views of the latest chassis as designed and built by the Wolseley Tool and Motor Car Co., Ltd., of Adderley Park, Birmingham. The engine has four horizontal cylinders, each 411n. bore by 6in, stroke, and gives out 24b.h.p. at 75a revolutions per minute. It will be seen that the crank-shaft lies transversely across the frame, and not longitudinally, as is the general practice in so many makes. The Wolseley engine is not governed, but, on the other hand, two throttles are fitted. One of these is on the steering pillar ; the second is attached to, and worked in conjunction with, the brake pedal. The usual Wolseley type of carburetter, placed in front of the engine, is fitted, and the ignition is high-tension, by means of accumulators and an induction coil. Our illustrations give a clear view of the gilled tube radiator, which is divided into two portions, one being placed on each side of the frame, and practically at each end of the driver's seat. On the inner side of each portion of the radiator is a fan, and these fans are mounted on a common axle—which is driven by a fiat belt from an extension of the crank-shaft. A capacious water tank, which is designed to hold enough for the engine to run a full day without replenishment, is placed in front of the dashboard. The petrol tank carries about 12 gallons of spirit, and, as the consumption of the engine amounts to x gallons per hour on average roads, this quantity enables the vehicle to be run for over 9t hours. The gear-case has a threepoint suspension--an important feature in the construction of public service vehicles which have to travel over

indifferent roads. This box is also absolutely grease-tight, and, as can be seen, is of very strong and rigid construction, Four speeds are fitted, all operated by a lever at the driver's right hand, and when the engine is running normally, these yield speeds of 2, 5, 8, and £3 miles per hour respectively. The reverse is about five miles per hour. The transmission is first of all by means of a heavy Renold's silent chain, driven directly off an extension of the right-hand side of the crank-shall; Ibis chain runs at its rearward end on a sprocket bolted to the female portion of the cone clutch. The male portion is on the first shaft in the gear box, from which the power is taken by the transverse differential shaft, with a sprocket at each end carrying the two chains to the back wheels. Two brakes are fitted,

both of the metal-to-metal lype. The first is composed of ,eginental plates, which work on drums fixed to the ends of the differential shaft and is operated from the foot-plate by a lever at the driver's right hand; the second is a band brake, which grips a water-cooled drum on the gear box high-speed countershaft, and is brought into action by depressing a foot pedal. As will be gathered from the illustrations, the chassis is of simple and strong construction, and it is built up of heavy channel steel, having cross members of the same material where necessary to further strengthen it. By placing the engine underneath the driver's seat, more room is available for the body of the vehicle than is generally found. The length of the chassis behind the dash is 1 5ft. 6in.; the top of the frame is 2ft. 7in. from the ground.