Seddon + Six 354 1 Real Winner

Page 82

Page 83

Page 84

Page 85

If you've noticed an error in this article please click here to report it so we can fix it.

New Perkins Direct-injection Oil Engine is Tested in 7-ton Chassis : Ample Power and Good Economy By John F. Moon,

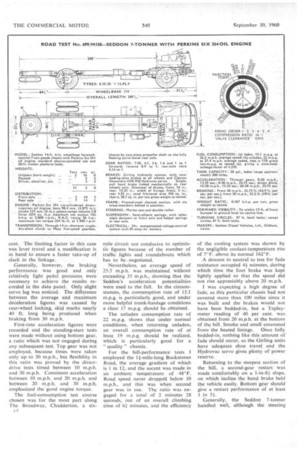

A.M.I.R.T.E. ONE of the first goods chassis to have ' the new Perkins 354 direct-injection oil engine (described in last _week's issue) is the Seddon 7-tonner. Several of these vehicles have been -operating with chosen customers since the beginning of this year and the initial results reported have been extremely favourable.

I carried out a full road test on such a vehicle about five months ago and found it to have a highly satisfactory overall performance. Compared with earlier Seddon 7-tormers—which had the Perkins P6 indirect-injection engine—the new model shows an improvement in fuel consumption in the order of 10 per cent.

Acceleration and hill-climbing are also far better. These results are even more remarkable because the chassis was tested with a single-speed axle, whereas the model tested in February, 1957, with the P6 unit, had a two speed axle.

The new Perkins engine has extremely good torque characteristics and, in the Seddon application, is fortunate in being matched to a Moss five-speed gearbox, the ratios of which suit the Six 354 torque curve admirably. The ratio steps give approximate second-, third-, fourthand top-gear speeds of 10 mph., 20 m.p.h., 33 m.p.h. and 52 m.p.h., respectively, whilst top-gear acceleration tests showed remarkable transmission and engine smoothness from as low a speed as 8 m.p.h.

Another important characteristic of the new engine is the reduction in engine. noise compared with some other Perkins engines: the exhaust note is pleasantly deep, even with a short exhaust system, and makes the unit sotind appreciably larger than it really is. Only when the engine speed approaches its governed maximum of 2,800 r.p.rn. do mechanical and coin •

bustion noi, ses become at all obtrusive. Seddon staff told me that during the cold 'weather at the beginning of the year the engines were consistent "firstgo " starters and the use of the Therrnostart induction-manifold cold start device was not really necessary. A fast fuel-consumption test through an urban area along a road dotted with traffic signals produced a consumption rate of 15.1 m.p.g. at an average speed of 25.5 m.p.h. with a 7+-ton payload. Unladen, the Seddon gave 22 m.p.g. at 27.4 m.p.h. average speed along the same route.

The liveliness of the power unit is shown by the ability of the 7-tonner to reach 30 m.p.h. from a standstill in 24.75 seconds, which is about 12 seconds faster than the 1957 model

took for a similar test. The hillclimbing test further emphasized the good power characteristics of the Six 354, a Ii-mile climb being completed in 6 minutes—two-thirds of the time taken by the 1957 vehicle.

The vehicle offered for test was a 14-ft. 6-in.-wheelbase model with the standard plastics-panelled cab and a Seddon-built 20-ft. timber platform body. Ready for the road, it had a kerb weight of 3 tons 16 cwt. This is somewhat high for a nominal 7-ton chassis, but the design is particularly robust and is obviously capable of operating at higher gross weights than the 11 tons specified. Furthermore, some 5 cwt. could have been saved had a light-alloy platform body been fitted.

There are four basic models in the Seddon 7-tonner range, and these vary only in respect of wheelbase. The shortest model, with a wheelbase of 7 ft., is intended for use as a tractive unit at a gross train weight of 16 tons. Next ccimes a 9-ft.-wheelbase tipper chassis, whilst the two general-haulage models have wheelbases of 14 ft. 6 in. and 13 ft. 6. in.

The Perkins engine is unit-mounted with the Moss constant-mesh gearbox and the Borg and Beck AStype 14-in.-diameter clutch has Girling hydrostatic actuation with a sealed ball-bearing, release, a system, which makes periodic adjustment unnecessary.

A • Moss single-speed spiral-bevel axle is standard equipment and is offered with one reduction ratio only —6.16 to 1. It is rated for a maximum loading of 7+ tons, the rating of the front axle being 3+ tons. Plain phosphor-bronze bushes are used for the king-pins. .

A Clayton Dewandre I-ISR.950

• Hydrovac, with . integral reservoir,•boosts the Girling hydraulic braking

system, which has two-leading-shoe units at front and rear. The new Clayton .Dewandre A.350 exhauster is employed to power the servo. This is a particularly compact unit weighing only 12 lb. and with a maximum length of 8+ in. It is designed to operate at speeds up to 3,000 r.p.m., at which it absorbs only 1.2 b.h.p.

• The chassis-frame side members are fin.-thick pressings with 2+-in. flanges and a maximum depth of 84in. The pressed-steel cross-members are bolted and the upper flanges of the side members are flat throughout their length. The semi-elliptic springs are 55 in. long at the rear and 50 in. long at the front, and eight-leaf helper springs are standardat the rear. Telescopic dampers are offered as optional equipment. The standard tyres are 8.25-20-in. (12-ply), mounted on B6.0 wheels, but 9.00-20-in, equipment is available at extra cost.

The standard cab is a relatively new unit of much simpler appearance than the rather attractive cab introduced for the earlier 7-ton models in 1956. In outline it is more like the slightly larger cab fitted to Seddon heavy-duty chassis, and consists of a timber frame clad with moulded plastics panels.

A two-piece wrap-round windscreen is .incorporated, but its base line is higher than I would have thought necessary, and the field of, vision is not as great as that of the 1956 design. To save cost, the cab is sparsely equipped with shelves and general stowage space, and only one windscreen wiper is fitted.

For my test the 7-tonner was carrying concrete-filled metal boxes and a few leaf springs, the combined weight of which was 7 tons 51 cwt. Of the test load, 6 tons were being carried by the rear wheels, the total rear-axle loading being 7 tons 14+ cwt.

Braking tests revealed high maxiMum retardation of 80 per cent. When making full-pressure stops from 20 m.p.h. and 30 m.p.h. both the rear wheels locked, which at times caused the vehicle to slew round to the right.

The hand-brake performance was a little disappointing, as the highest Tapley-meter reading that could be obtained from 20 m.p.h. was 25 per

cent. The-limiting factor in this case was lever, travel and a modification is in hand to ensure a faster take-up of slack in the linkage.

Generally, however, the braking performance was good and only relatively light pedal pressures were necessary to achieve the results recorded in the data panel. Only slight servo lag was noticed. The difference between the average and maximum deceleration figures was caused by rear-wheel locking, skid marks nearly 40 ft long being produced when braking from 30 m.p.h.

First-rate acceleration figures were recorded and the standing-start tests were made without using bottom gear, a ratio which was not engaged during any subsequent test. Top gear was not employed, because times were taken only up to 30 m.p.h., but flexibility in this ratio was proved by the directdrive tests timed between 10 m.p.h. and 30 m.p.h. Consistent acceleration between 10 m.p.h. and 20 m.p.h. and between 20 m.p.h. and 30 m.p.h. emphasized the good engine torque.

The fuel-consumption test course chosen was for the most part along The Broadway, Chadderton. a six

, 8

mile Circuit not conducive to optimistic figures because of the number of traffic lights and roundabouts which has to be .negotiated.

. Nevertheless, an average speed of 25.5 m.p.h. was maintained without exceeding 35 m.p.h., showing that the Seddon's acceleration potentialities were, used to the full. In the circumstances, the consumption rate of 15.1 m.p.g. is particularly good, and under more helpful trunk-haulage conditions a clear 17 m.p.g. should be obtained.

The unladen consumption rate of 22 m.p.g. shows that under normal conditions, when returning unladen, an overall consumption rate of at least 19 m.p.g. should be realized, which is particularly good for a " quality " chassis.

For the hill-performance tests I employed the 14-mile-long Buckstones Road, the average gradient of which is 1 in 12, and the ascent was made in an ambient temperature of 48°F. Road speed never dropped below 10 m.p.h., and this was when second gear was in use. The ratio was engaged for a total of 2 minutes 28 seconds, out of an overall climbing time of 61 minutes, and the efficiency of the cooling system was shown by the negligible coolant-temperature rise of 7°F. above its normal 162°F.

A descent in neutral to test for fade resistance occupied 4+ minutes, during which time the foot brake was kept lightly applied so that the speed did not rise appreciably above 20 m.p.h.

I was expecting a high degree of fade, as this particular chassis had not covered more than 100 miles since it was built and the brakes would not have been bedded-in, but a Tapleymeter reading of 40 per cent, was obtained from 20 m.p.h at the bottom of the hill. Smoke and smell emanated from the heated linings. Once fully bedded-in, nothing like this amount of fade should occur, as the Girling Units have adequate shoe travel and the Hydrovac servo gives plenty of power reserve. .

Returning to the steepest section of the hill, a second-gear restart was made comfortably on a 1-in-8; slope, on which incline the hand brake held the vehicle easily. Bottom gear should give a restart performance of at least 1 in 5+.

Generally, the Seddon 7-tonner handled well, although the steering tended to be a trifle heavy, particularly at low speeds. Castor effect was good, however, without being too fierce, Braking action was firm without being heavy and the gear-change was good, although the lever travel was a little excessive and the spring pressure against accidental engagement of first and reverse was not high enough to be wholly effeetiye.

The relative positions of the gear and hand-brake levers are not all they might be. When the hand brake is fully applied the gear lever hits it when selecting second gear.

had no time to carry out maintenance tests, but the maintenance of the chassis itself was dealt with in the report published on February 8, 1957. The engine should be an easy one to work on, as the Seddon cowling gives good access to it. The injectors are well exposed and have flange mountings, so that they will be simple to remove and replace, whilst the fuel filter is carried high up on the left front corner of . the cylinder head, Where it can be reached easily.

The main object of the test was to assess the merits of the new engine. Manufacturers who install Perkins engines as initial equipment will find that the Six. 354 will prove to be a "winner." The engine should also have a rosy future as a conversion unit.