MINIMIZING E JS-BODY WEIGHT

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

Current Tendencies in the Reduction of the Weight of Coachwork. Securing Rigidity and Strength With Less Weight. Varied Uses of Steel Tubing

OFTEN the bodybuilder is asked to estimate the weight of the body for which he is quoting. This is a request which will, in the future, be made more frequently. To build lightly, without impairing strength or increasing the cost of construction and maintenance, is one of the chief problems of to-day.

Much success has been achieved, owing to improved methods of framing and mounting the body, as well as to the co-operation of the metallurgists and the manufacturers of body fittings and equipment.

The last-named are fully alive to the importance of the weight factor, and usually give the necessary information in their literature and announcements without having to be asked for it, whilst in some instances, with an eye to the promotion of export trade, the metric equivalents also are stated.

The thickness of the bottom framework was reduced in the first

place in order that the floor might be as close as possible to the chassis. This lowering of the floor led to the introduction of the outrigger, which in turn has been the means for saving weight, because the side overhang is supported by a well

secured cantilever bracket; and less substance is required in the crossbearers.

With regard to the main structure of the body the composite form of construction still predominates, but metal components, brackets and other reinforcements are of increasing importance, as the amount of woodwork used is reduced.

The fixed channels in which the adjustable window moves increase the rigidity of the wood pillar to which they are attached. Hitherto the thickness of the plank from which the pillar is cut has depended partly on the allowance made for a rebate or groove to accommodate the window. Now, the pillar is cut without this allowance, and any rebate required is made up by screwing on a separate wood fillet.

If half-drop windows be used there is the opportunity for adopting the box-girder form of construction at the waist rail. No casing below this level is necessary, consequently there may be a small top and bottom rail connected by an outer rail of moderate substance and an inner one of plywood.

If the overall thickness be too small for building up a hollow spar, the wood rail is lightened out on the inner side where the substance is not required for making a joint or for the attachment of fittings.

When timber is not used as a part

of the framework. but as a filler, such as in a channel hoop-stick or as a distance piece, the lighter material, such as spruce, should not be overlooked.

The enclosure of the upper deck of the double-deck bus has led to the breaking away from conventional ideas of roof construction. A thin roof structure is desirable, so that it adds little to the overall height, but of greater importance is the saving of weight at the highest paint of the vehicle, owing to its effect on stability.

Many of these roofs are of aluminium, with the edges of the transverse panels interlocked and the whole stiffened with mouldings. Further support consists of a pair of longitudinals to which the upper ends of the grab poles are attached.

Failing the adaptation of this type of roof . for the single-decker which does not carry luggage, weight may be saved by using shaped-plywood roof panels of maximum size. Although with this kind of roof covering, boxvans have been built without hoop-sticks, it is not suggested that they be eliminated from the wider bus roof, but ' there is scope for reducing their number.

The omission of a ceiling panel may be considered retrogressive, but, on the other hand, the hoopsticks may be rounded on the underside and the roof between them lined with leather-cloth.

There does not appear to be much opportunity for reducing the weight of the staircase. Something could he done in thiS direction if -dimensions were standardized, so that the treads or risers, or both, could be made as pressings.

Armoured plywood might be used for these parts, also when the staircase is enclosed and there is an inside metal panel, the staircase may be attached to this panel Instead of using a separate outer stringer.

One of the strongest materials in comparison with its weight is drawn

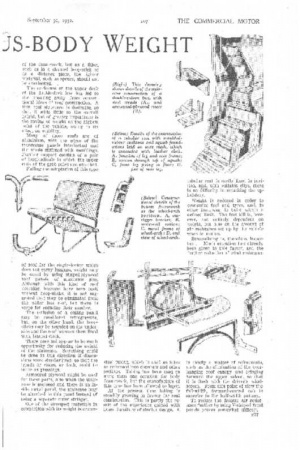

steel tubing, which is used as tubes or reformed into channels and other sections. Tubing has been used on more than one occasion for body framework, but the manufacture of this type has been allowed to lapse.

At the present time tubing is steadily growing in favour for seat construction. This is partly the result of the experience gained with house furniture of similar design. A

tubular seat Is easily' fixed in joosition, and, with suitable clips, there is no difficulty in attaching the upholstery.

Weight is reduced in order to economize fuel and tyres, and, in other instances, to build within o defined limit. The fuel bill is, however, not entirely dependent on weight, but also on the amount of air resistance set up by the vehicle when in motion.

Streamlining is, therefore, important. Much attention has already been given to this factor, and the further reduction of wind resistance is chiefly a matter of refinements, such as the elimination of the overhanging roof canopy and bringing forward the upper saloon, so that it is flush with the driver's windscreen. From this point of view the full-width, forward-control cab is superior to the half-width pattern.

To reduce the frontal air resistance further by using V-shaped front panels proves somewhat difficult.