Working together is one way forward

Page 19

Page 20

Page 21

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

THE SHOW worth it for the perator of vehicles below the .5 tonnes gross vehicle weight Ireshold? As there are some enuinely new lightweights, and number of modifications and :finements to existing models, o matter what the aggravation Ivolved in reaching and/or stayig in the Birmingham area, the nswer must be yes. The show rovides an unmatched opporJnity to compare features of all ompeting vehicles in any cateory at one time.

On trade days, shrewd buyers /ere to be seen asking represen:tives the same questions on ach stand. However, this year ome manufacturers with feet in oth the commercial vehicle and ar camps have made that exerise unnecessarily difficult by lot having knowledgeable nough representatives on their tands in the commercial vehicle all. Often, I found them in Halls and 2 on the more exotic car tands. Sometimes, astonthingly, detailed information imply was not available. Perhaps the lack of enthusiasm displayed by the representatives of some Japanese vehicle manufacturers can be explained by their feeling of frustration at not being allowed to import as many vehicles as they would like ... Perhaps not.

BL subsidiaries these days have no need for excuses and there is a marked mood of optimism on the Austin Rover and Freight Rover stands.

Austin Rover gives pride of place to the newly introduced Metro vans. Somewhat confusingly, like all vans and pick-ups from the Austin Rover Group the Metro is a Morris vans In its standard form a disadvantage of the new model's load compartment shape is the deep boot sill which makes loading heavy objects an awkward task, but BL offers a solution to this problem in the shape of the Unipart Easy Load floor which retails at £83.50.

This plywood floor sits on a steel frame fixed to the wheel arches and provides a full-length platform which is flush with the rear sill height. It is designed to carry a maximum of 272kg (600Ib) and is supplied complete' with a useful bulkhead. A number of potential Metro buyers will feel that this floor, useful as it is, should be supplied as standard equipment with the new van.

This is the first British Motor Show to have a Freight Rover stand, since the new BL subsidiary company has been in existence only since January 1981, when the light commercial sector of BL's business was at a low ebb.

Much of the credit for the dramatically improved Sherpa sales figures since that date must go to Tony Gilroy, Freight Rover's managing director. He spoke with confidence at the Show of more big orders and of increasing production at Freight Rover's Common Lane plant in Birmingham from its current level of 300 to 390 vehicles a week from the beginning of next month. Output at the beginning of this year was 180 a week. Freight Rover has added a new model to the Sherpa range already widened earlier this year with the launch of the revamped "K2". The new Combi model will go on sale early in 1983. It is based on the 250 Minibus bodyshell and running gear and is a nine-seater with 1.8 5cum (66cuft) of luggage space.

Standard equipment on the Combi includes a sliding sidedoor, and gas-strut-assisted tailgate for access to the luggage area. With the exception of the front disc brakes, the mechanical features of the Combi are identical to those of other Sherpa models. The front brakes have four pot calipers to comply with private car regulations.

On the details and timing of the MT210 development programme, which will take Freight Rover's light commercials from 2.8 to 3.5 tonnes gvw, Tony Gilroy would not be drawn, except to say that the Common Lane plant's production lines had already been altered to suit the new models, which will comprise vans, chassis cabs and buses.

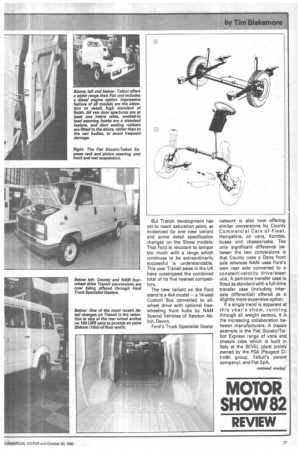

Ford is even more reticent about its Triton project, not surprisingly since this is the code name for the model which eventually will replace the Transit, and "eventually" means 1986 at the earliest. Triton is not yet a Ford "approved programme", and even if the company's top executives gave approval tomorrow it would take at least three years to reach the "job one" ;tage. But Transit development has yet to reach saturation point, as evidenced by one new variant and some detail specification changes on the Show models. That Ford is reluctant to tamper too much with a range which continues to be extraordinarily successful is understandable. This year Transit sales in the UK have outstripped the combined total of its five nearest competitors.

The new variant on the Ford stand is a 4x4 model — a 14-seat Custom Bus converted to allwheel drive with optional freewheeling front hubs by NAM Special Vehicles of Newton Abbot, Devon.

Ford's Truck Specialist Dealer network is also now offering similar conversions by County Commercial Cars of Fleet, Hampshire, on vans, Kombis, buses and chassis/cabs. The only significant difference between the two conversions is that County uses a Dana front axle whereas NAM uses Ford's own rear axle converted to a constant-velocity drive/steer unit. A part-time transfer case is fitted as standard with a full-time transfer case (including interaxle differential) offered as a slightly more expensive option.

If a single trend is apparent at this year's show, running through all weight sectors, it is the increasing collaboration between manufacturers. A classic example is the Fiat Ducato/Talbot Express range of vans and chassis cabs which is built in Italy at the SEVEL plant jointly owned by the PSA (Peugeot Citroen group, Talbot's parent company), and Fiat SpA. In deference perhaps to Talbot's inherently greater strength in the UK, that company's range of vehicles initially available in this country is wider than Fiat Auto's (ten as against five). Both ranges make their UK debut at this show and both are likely to be widened next year, Fiat certainly expects then to introduce more rhd variants, including probably a diesel version which currently is available only as a Talbot Express.

The SEVEL plant, which went into full production in autumn 1981 has a capacity of 80,000 units per year and has produced 40,000 Ducatos to date. In Italy, where the Ducato was first introduced, it has already won the lion's share of the 2,450kg to 3,100kg gvw market with seven basic versions, 16 variants and three engine options.

In all other markets but the UK, the semi-forward control, front-wheel-drive vehicle has a column gear-change. All rhd models have floor-mounted gear levers.

There must be many an Iveco (UK) van salesman who is somewhat surprised to find such a serious new rival product to the Daily as the Ducato coming indirectly from his own company.

It could be argued that the two ranges appeal to different van buyers, in that the Daily is effectively a "truck-derived van" in contrast to the Ducato which is more closely related to passenger cars.

However, there is no denying that there is an overlap — the S range (Daily) has gvws-from 3 to 3.5 tonnes and the top weight in the Ducato/Express range is 3.1 tonnes. Rumour has it that Iveco was offered the chance of marketing Ducatos but turned it down for "political reasons."

Nevertheless it is clear that Iveco is intent on selling more vehicles in this market sector and the one above it, in which the Z range competes, not only in the UK but right across Europe. The number of variants is being increased and detail improvements are being made.

Iveco's solution to the body corrosion problem which afflicted its earlier vans is to change the side wall construction from vertical seams to longitudinal ones. The result is a reduction of two-thirds in the length of welded seams in the body.

Of course, the other side of the coin for Iveco van operators with careless drivers is likely to be an increase in the size of body repair bills.

At the same time as changing its van body construction, Iveco has also changed its electrocoat paint process, from anodic to cathodic. This system is now generally accepted to be the one that gives the most thorough paint coverage — the body shell is negatively charged and the paint particles positively charged.

Other changes to the Z range include automatic brake adjusters front and rear, an increase in front brake lining width on the 60.10 model from 80mm (3.15in) to 100mm (3.94in) and an increase in rear overhang on the same model from 50 per cent of the wheelbase to 60 per cent.

This latter modification coincides with a change in the Italian regulations on overhang, bringing them into line with this country.

A further move towards standardisation on the Z range comes from the fitment of a Fiat five-speed gearbox (as used on the 60.10) to the 79.10 in place of the previously used ZF fivespeed model.