THREE NEW A.E.C. MO

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

TWO new underfloor-engined passenger vehicles and an 8-ton goods chassis have been added to the A.E.C. range. Two new oil engines and a five-speed syncromesh gearbox have also been introduced, and a single-reduction spiral-bevel rear axle is used for the first time, One of the passenger vehicles—the Reliance—is a 41-44-seater of conventional design with separately mounted .body. The other—the A.E.C.-Park Royal Monocoach—of similar seating capacity, has an integral body and chassis. The Mercury goods chassis, with forward-mounted engine, has been designed for an 8-ton payload with a.gross weight of 12 tons.

Two types of power unit are offered in the Reliance—the AH410 or the AH470. The A1-1410 has a piston-swept volume of 6.75 litres and develops a maximum of 98 b.h.p. at 2,000 r.p.m., whilst the AH470 is of 7.75-litrecapacity with a maximum output of 112 b..h.p. at 2,000 r.p.m. Respective maximum torque figures are 285 lb.-ft. at 1,200 r.p.m., and 325 lb.-ft. at 1,100 r.p.m.

With the exception of the cylinder liners and pistons, the technical details are common to both types. The essential differences between the horizontal and vertical versions are confined mainly to the sump, engine mounting and location of the dynamo.

They are six-cylindered, four-stroke, direct-injection units with a compression ratio of 1.6 to 1. Masked inlet valves are used in conjunction with pistons having an offset toroidal cavity in the crown. The one-piece cast-iron crankcase and cylinder block carries wet-type liners, and there are two cylinder heads, each covering three bores.

The crankshaft is carried in seven steel-backed copper-lead bearings, similar types of bearing being . used in the big-ends of the alloy-steel connecting rods. The overhead valves are operated, through rockers, by flat-faced tappets and push-rods from a four-hearing camshaft mounted low down in the engine casing. Camshaft drive is from a train of helical gears carried , in the front of the engine casing. Either C.A.V. or Simms fuel-injection equipment can be fitted, the pump being driven in tandem with an exhauster or compres • .a8 or, according to the braking system installed. Oil is upplied to the bearings by a gear-type pump which lraws its supply from a wet sump.

A pressure of 3-5 p.s.i. is maintained in the cooling ystem, the radiator of which is mounted below floor evel. The high-speed fan is shaft-driven from the engine crankshaft through a Hardy Spicer needle-rollerbearing joint with a self-aligning bearing arranged at the fan end.

A hydraulically operated 151-in. single-plate clutch takes the drive to a five-speed syncromesh gearbox unit mounted with the engine. It provides ratios of 6.25, 4.4, 2.65, 1.56 and 1 to 1, and a 6.25 to 1 reverse. The choice of either a 4.7 to 1 or 5.22 to 1 axle is given. As an alternative to the five-speed syncromesh gearbox, a four-speed epicyclic unit with automatic centrifugal clutch is available.

From the gearbox the drive to the single-reduction spiral-bevel rear axle is by a Hardy Spicer 1,000-type propeller shaft with needle-roller-bearing joints. The axle shafts are fully floating.

On home-market models the maximum frame depth is 8 in. and thickness I in., flanges being 2+ in. On overseas versions the dimensions are 8+ in. by 24 in. by Ain. The top flange of the frame is flat throughout most of its length, being carried down at the front and rear to a smaller section.

At the front, the semi-elliptic springs, which are 4 ft. 8 in. long, are mounted beneath the frame side members, whilst at the rear they are carried outside the frame on brackets bolted to it. All springs are provided with safety anchor clips at the eyes: Resilient bumper pads are fitted to both axles, with telescopic hydraulic dampers on the front axle.

Brake drums are 15+ in. in diameter, those at the front having a liner width of 4+ in. and those at the rear 6 in. On the home version, a triple-servo vacuum braking system is employed, whereas air-pressure braking is used on overseas chassis. If the epicyclic gearbox is required, only air-pressure braking can be installed, but in the case of the syncromesh box either system can be fitted. The worm and nut steering gear has a ratio of 32 to 1, 54 turns of the 20-in, steering wheel taking the road wheels from lock to lock.

Three-piece wheels with twins at the rear are equipped with 9.00-20-in. tyres. There are 10 4-in. B.S.F. studs to each wheel assembly.

Either C.A.V. or Simms 24v. electrical equipment is available.

The principal dimensions of the Reliance chassis are: Wheelbase, 16 ft. 4 in.; overall width, 8 ft.; overall length, 29 ft. 64 in.; front overhang, 5 ft. 14 in.; mean frame height, laden, 2 ft. 91 in. The gross rating is 91 tons.

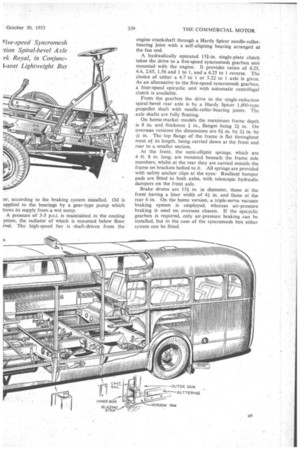

In the construction of the A.E.C.-Park Royal Monocoach, mechanical components as used in the Reliance chassis are employed. The underframe consists of eight deep-section cross-members and two comparatively light longitudinals threaded through the cross-members, to which they are welded.

Resistance to Bending Although this frame possesses considerable strength in the transverse plane, it is the integral construction of the body which imparts the necessary resistance to bending in the longitudinal plane.

The main strength-giving members ofthe body sides are the pillars, crib, waist and cant rails and the interior truss panels. In general arrangement, the Monocoach is a six-bay design in which the seven main body pillars are in light alloy of a special box section having a 3-in. flange.

It is to this flange that the main constructional. members are solid-riveted, the pillars being rigidly secured to the ends of the underframe cross-members. Hot riveting is employed at this point, the mild-steel rivets used being of 4-in, and diameter.

An important bodyside structural member is the truss panelling, and this again is solid riveted to the inner face of the pillar flange. The panelling, which is of 18 g. light alloy, extends from the floor-supporting crib rail—a 11 in. by 4 in. Mild-steel angle member—to the full depth up to the waist rail. The waist rail is a lightalloy extrusion of special section having three flanges. The outer face of one flange coincides with a face of the pillar flange to which it is riveted, a second flange supports the top edge of the truss panel, and the third one carries the outer panelling, the edge of the window pan and the exterior cover strip.

Cant-rail Construction Special attention has been given to the cant rails, which are light-alloy extrusions fabricated as full-length units and secured to the pillar Flanges by solid rivets. The channel section employed is 14 in. wide, with one vertical flange measuring 4 in. and the other 4 in. This section enables the roof hoopsticks to be attached directly to the rail without the use of brackets, and the unusual depth makes local roof trussing, as over the doorway, unnecessary. Seven hoopsticks form the main transverse roof members and these are in 11 in.-deep light-alloy top-hatsection material. The 18-g. light-alloy roof panelling also contributes to the general rigidity of the body assembly. Light alloys are also employed for the exterior panelling and the inner skin of the roof, whilst the fwo-passenger seats are of a special lightweight pattern. The weight of the bodywork, excluding the underframe, is under 2 tons, the body shell alone Weighing only ton 13 cwt. The jack-knife folding entrance door is at the front with the usual emergency door arranged centrally at tilt rear. With the exception of the slight ramp at tin entrance, the floor is flat; it is covered with Fin. plastic linoleum. • The foam-rubber cushions and rubberized hair-fillet squabs are trimmed in a green figured moquette Adding to the pleasing appearance of the interior an the parcel racks, which are cantilevered from cant-rai level. The racks are edged with polished aluminiun moulding with plastic insets. Being trimmed on MI underside with similar material to that used on till interior roof covering, they blend well with the genera interior finish.

Jelly-mould lights are installed beneath the parct racks and there are four " concealed " lamps arrange( on the centre line of the roof. Intake and extract° units in the roof provide for the ventilation of th saloon.

In the goods-vehicle chassis the general specificatioi in respect of the major components follows closely tha of the Reliance passenger chassis, but there is a numbc of essential differences.

The two engines available are designated respective! the AV410 and the AV470, the general classificatic following that of the passenger-chassis units. The engir of the Mercury is forward-mounted, the drive to the fly( speed syncromesh gearbox being through a 14-in diameter single-plate clutch. A single propeller shaft used in the short-wheelbase tractor version, but on 013-ft. 6-in. and 16-ft. 3-in.-wheelbase chassis, a two-piec component with a self-aligning intermediate bearing employed.

A choice of two ratios is given with the spiral-bev axle, these being 5.87 and 6.28 to 1. On the hors models a vacuum-hydraulic braking system is provide, with air-pressure braking for the overseas version.

Front springs, which have telescopic hydraul dampers, are 4 ft. 34 in. long, those at the rear beir 4 ft. 64 in. long, the helper springs fitted having a effective length of 3 ft. 3 in.

The maximum depth of the frame is 10 in., ti flanges being 3 in. wide and the thickness 7/32 i Channel-section steel is also used for the cross-member The three-piece wheels carry either 9.00-20-in. 12-ply I 10.00-20-in. tyres.

Good visibility is a feature of the full-fronted ca which has two rear corner lights and one in the cents The shallow bonnet is contained within the cab in which it extends for three-quarters of its length. T1 engine Oil filler, dipstick, fuel-injection pump ar injectors are easily accessible.

The Mercury is to be produced in wheelbases I 16 ft. 3 in., 13 ft. 6 in., 11 ft. and 9 ft.