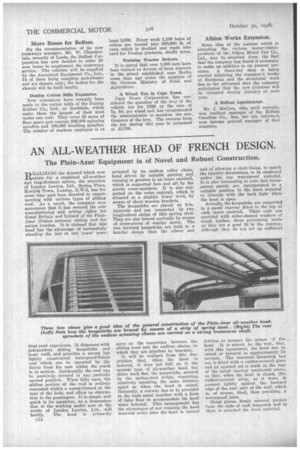

AN ALL-WEATHER HEAD OF FRENCH DESIGN.

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

The Plein-Azur Equipment is Of Novel and Robust Construction.

REALIZING the demand Which now exists for a combined all-weather and long-distance saloon, the attention or London Lorries, Ltd., Spring Place, Kentish Town, London, N.W.5, has for some time past been directed to experimenting with various types of sliding roof. As a result, the company now announces that it has secured the sole manufacturing and selling rights• for• Great Britain and Ireland of the PleinAzur (Dubos patents) sliding roof for saloon coaches. It is claimed that this head has the advantage of successfully' standing the test of two years' prze.-

tieal road experience. It dispenses with independent sliding hoopsticks and loose twill, and provides a strong but lightly constructed waterproof-fabric roof which can be operated by the driver from his seat whilst the coach is in motion. Incidentally the roof can be positively secured in any partially opened position. When fully open, the sliding portion of the roof is entirely concealed within a recess formed at the rear of the body, and offers no obstruction to the passengers. It is simple and quick in its operation, as a demonstration of the working model now at the works of London Lorries, Ltd., will testify. The head is primarily 024 actuated by an endless roller chain, hand driven by suitable gearing and running in grooves in an inner contrail, which is supported fore and aft by the sturdy cross-members. It is also supported on the outer contrail, which is situated at a slightly lower level, by means of short wooden brackets.

The hoopsticks are placed at S-in. intervals and are connected by two longitudinal strips of thin spring steel. They are also braced centrally by means of cross-pieces of similar metal. The two forward hoopsticks are built to a heavier design than the others and serve as the connection between the sliding hood and the endless chains, to which they are attached by brackets. It will he realized from this des-: cription that, when the hood is lowered, it does not fold as in the normal type of all-weather head, but slides back flat, the hoopsticks, secured by the spring-steel strips, remaining, relatively speaking, the same distance. apart as when the hood is raised. Naturally, a runway has to be provided in the back panel together with a form of false floor to accommodate the hood when lowered. This arrangement has the advantages of not creasing the hood material every time the head is opened and of allowing a cloth lining, to match. the interior decorations, to be employed under the top waterproof material. It is also interesting to note that trausparent panels are incorporated in a suitable position in the hood material to coincide with the back light 'When the head is open..

Actually, the hoopsticks are supporttd in a -metal runway fitted to the top of each inner cantrail. Their ends are provided with roller-shapedwashers of tough leather, these preventing rattle as they are a good fit iii the runway, although they do not set up sufficient

friction to hamper the action f the head. It is stated, by the way, that, with this equipment, the hood can be raised or lowered in approximately. 20 seconds. The rearmost hoopstick but one is fitted with a rubber-covered plate and an upward set is made at the rear of the metal runway mentioned above, so that, when the head is closed, this rubber-covered strip, as it were, is pressed tightly against the forward edge of the rear part of the roof, which is, of course, fixed, thus providing a waterproof. joint.

Metal pieces,, firmly secured, project from the ends of each hoopstich and to these is attached the hood material