A NOVELTY IN BOGIE

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

SIX

WHEELERS.

drANE of the most success ful makes of passenger chassis on the British market is certainly the Gifford, made by the Gilford Motor Co., Ltd., 465 and 471a, Holloway Road, London, N.7, and it has won an almost predominant position in the sphere of long-distance coaching, which is admitted by all who are cognizant of the facts to be perhaps the most exacting trial of endurance which it is possible for a regular-service vehicle to experience.

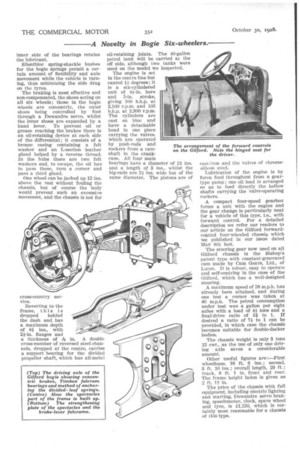

Until recently the company confined itself to the production of four-wheeled chassis, but for some time it has been experimenting with a rigidframe six-wheeler and as a result has evolved a remarkable model known as the 6 W.O.T., which embodies some unusual but practicable features, of which, possibly, the most interesting is the original form of chassis-frame construction. The rear of the frame is formed in the well-known spectacles shape, but divided longitudinally in such a manner that the upper part is in one with the main side members, whilst the lower portion is bolted into position and additionally secured by substantial plates bolted on to the outside of each side member and slotted for a reason which we will explain later. The halves of the spectacles carry robust brackets acting as anchorages for the 3 per cent, nickel-steel tube which forms the fulcrum member of the fourwheeled bogie, the diameter of this tube being decreased at the sides so that it is positively located by the brackets, which are also split. To remove the whole bogie unitconstituting the two axles, the four inverted semi-elliptic springs and the fulcrum bar—it is only necessary to release the four brake connections, remove at each side two bolts on the side plate, six at the ends of the spectacles and four on the fulcrumtube brackets, when the whole lower portion of the spectacles drops and the bogie can be wheeled out over it, the fulcrum tube passing down via the slots in the side plates to which we have already referred. It is obvious that this construction does much to facilitate repairs and general maintenance.

Much of the success of a sixwheeler naturally depends upon the design and strength of its rear axles and their suspension. In the Gilford

the drive is taken through the bogie forward axle only, the worm being underneath. The rearmost axle is of tubular construction and the two are connected by a Goodyear type telescopic torque member with Silentbloc bushes for its joints. The torque member also constitutes an effective pneumatic cushioning device, for a cork gland between the outer and inner tubes prevents the escape of air. So efficient is the seal that in order to fit the parts into each other small air-release plugs must be removed temporarily. If particularly desired it is a simple matter to fit two driving bogie axles, and the bogie has been designed with this in view.

Both the bogie axles are of Kirkstall make with P.B. worm gearing in the one, whilst the bogie springing is arranged by Woodhead and embodies the latest type of dividedmain-leaf spring. The springs are mounted in pairs on massive centre blocks cut from the solid steel. In 'the case of the upper spring at each side, the inner turned-over ends rest in beds formed by drilling holes right through the block, whilst the whole spring is sunk into a deep slot in the block. The lower spring is located by the inner ends of the leaves dropping into slots in a bottom plate bolted and keyed to the block.

The spring fulcrum blocks are mounted on taper-roller bearings on the fulcrum bar, the adjustment for these being similar to that provided for the wheels, whilst the bar forms a reservoir for oil to lubricate the bearings. A felt gland ring at the Inner side of the bearings retains the lubricant.

Silentbloc spring-shackle bushes for the bogie springs permit a certain amount of flexibility and axle movement while the vehicle is turning, thus minimizing the side drag on the tyres.

The braking is most effective and non-compensated, the shoes acting on all six wheels; those in the bogie wheels are concentric, the outer shoes being controlled by foot through a Dewandre servo, whilst the inner shoes are expanded by a hand lever. To prevent oil or grease reaching the brakes there is an oil-retaining device at each side of the differential; it consists of a bronze casing containing a felt washer and an L-section leather gland helped by a reverse thread. In the hubs there are two felt washers and, to escape, the oil has to pass these, turn a corner and pass a third gland.

One wheel can be jacked up 12 ins. above the rest without fouling the chassis, but of course the body would prevent such an excessive movement, and the chassis is not for cross-country service.

Reverting to the frame, this is dropped behind the dash and has a maximum depth of 81 ins., with 21-in. flanges and a thickness of in. A double cross-member of reversed steel channels, dropped at the centre, carries a support bearing for the divided propeller shaft, which has all-meta I oil-retaining joints. The 40-gallon petrol tank will be carried at the off side, although two tanks were used on the model we inspected.

The engine is set in the centre line but canted 11 degrees; it is a six-cylindered unit of 41-in. bore and 5-in, stroke, giving 100 b.h.p. at 2,100 r.p.m. and 105 b.h.p. at 2,300 r.p.m, The cylinders are cast en bloc and have a detachable head in one piece carrying the valves, which are operated by push-rods and rockers from a camshaft in the crankcase. All four main bearings have a diameter of 24 ins. and a length of 3 ins., whilst the big-ends are 21 ins, wide but of the same diameter. The pistons are of cast-iron and the valves of chromesilicon steel.

Lubrication of the engine is by force feed throughout from a geartype pump ; one oil lead is arranged so as to feed directly the hollow shafts carrying the valve-operating rockers.

A compact four-speed gearbox forms a unit with the engine and the gear change is particularly neat for a vehicle of this type, i.e., with forward control. For a detailed description we refer our readers to our article on the Gilford forwardcontrol four-wheeled chassis which we published in our issue dated May 8th last.

The steering gear now used on all Gilford chassis is the Bishop's patent type with constant-generated cam made by Cam Gears, Ltd., of Luton. It is robust, easy to operate and self-centring in the case of the Gilford, which has a well-designed steering.

A maximum speed of 58 m.p.h. has already been attained, and during one test a corner was taken at 40 m.p.h. The petrol consumption under test was a gallon per eight miles with a load of 41 tons and a final-drive ratio of 5f to 1. If desired a ratio of 71 to 1 can be provided, in which case the chassis becomes suitable for double-decker bodies.

The chassis weight is only 3 tons 15 cwt., as the use of only one driving axle saves a considerable amount.

Other useful figures are :—First wheelbase, 16 ft. 6 ins.; second, 3 ft. 10 ins. ; overall length, 29 ft.; track, 6 ft. I in. front and rear. The frame height laden is given as 2 ft. 1 f in. The price of the chassis with full equipment, including electric lighting and starting, Dewandre servo braking, speedometer, clock, spare wheel and tyre, is £1,150, which is certainly most reasonable for a chassis of this type.