TITAN

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

WINS ITS SPURS

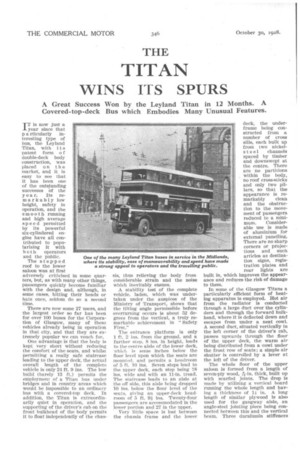

IT is now just a year since that particularly intereSting type of bus, the Leyland Titan, with Its patent form o f double-deck body construction, was placed en the market, and it is easy to see that it has been one of the outs!anding successes of the year. Its remarkably low height, safety in operation, and the smooth running and high average speed permitted by its powerful six-cylindered engine have all contributed to popularizing it with

b o t It operators and the public.

The Stepped roof to the lower saloon was at first adversely criticised in some quarters, but, as with many other things, passengers quickly become familiar with the design and although, in some cases, hitting their heads or hats once, seldom do so a second time.

There are now some 27 users, and the largest order so far has been for over 100 buses for the Corporation of Glasgow, many of these vehicles already being in operation in that city, and that they are extremely popular we can vouch for.

One advantage is that the body is kept very short without reducing the comfort of the seats, and whilst permitting a really safe staircase leading to the upper deck, the actual overall length of the complete vehicle is only 24 ft. 9 ins. The low build (barely 13 ft.) permits the employment of a Titan bus under bridges and in country areas which would be impossible to an ordinary bus with a covered-top deck. In addition, the Titan is extraordinarily quiet in operation, and the supporting of the driver's cab on the front bulkhead of the body permits it to float independently of the chas sis, thus relieving the body from considerable strain and the noise which inevitably ensues.

A stability test of the complete vehicle, laden, which was undertaken under the auspices of the Ministry of Transport, shows that the tilting angle permissible before overturning occurs is about 52 degrees from the vertical, a truly remarkable achievement in "Safety First."

The entrance platform is only 1 ft. 2 ins, from the ground, and a further step. 8 ins, in height, leads to the centre aisle of the lower deck, which is seine inches below the floor level upon which the seats are mounted, and permits a headroom of 5 ft. 10 ins. Seven steps lead to the upper deck, each step being 18 ins, wide and with an 11-in. tread. The staircase leads to an aisle at the off side, this aisle being dropped 10 ins, below the floor level of the seats, giving an upper-deck headroom of 5 ft. 94 ins. Twenty-four passengers are accommodated in the lower portion and 27 in the upper.

Very little space is lost between the chassis frame and the lower deck, the underframe being constructed from a number of cross sills, each built up from two nickelsteel channels spaced by timber and downswept at the centre. There are no partitions within the body, no roof cross-sticks and only two pillars, so that the appearance is remarkably clean and the obstruction to the movewent of passengers reduced to a minimum, Considerable use is made of aluminium for external panelling. There are no sharp corners or projections and such articles as destination signs, registration plates and rear lights are built in, which improves the appearance and reduces the risk of damage to them.

In some of the Glasgow Titans a particularly efficient form of heating apparatus is employed. Hot air from the radiator is conducted through a large duct over the cylinders and through the forward bulkhead, where it is deflected down and escapes from under a neat cowl. A second duct, situated vertically in the left corner of the driver's cab, passes upwards through the floor of the upper deck, the warm air being distributed from a -cowl under the front row of seats; a simple air shutter is controlled by a lever at the left of the driver.

The whole floor of the upper saloon is formed from a length of

seven-ply wood, thick, built up with scarfed joints. The drop is made by utilizing a vertical hoard running the whole length and having a thickness of I* in. A long length of similar plywood is also used for the gangway aisle, an angle-steel jointing piece being connected between this and the vertical beam. Three duralumin stiffeners

of inverted-U shape pass across the upper floor, and, of course, the whole construction is well stiffened by the front and rear bulkheads, so that, although light, it is extremely strong.

It will not be necessary for us to go fully into the design of the chassis, as this was dealt with when the vehicle was first produced, but it may. be of interest to refer to a few of its many features of interest and merit.

The frame is almost a work of art. It is upswept at the front and slightly inswept, arched over the rear axle, cut short immediately behind the axle and provided with separate drop members strongly riveted to the side members. Tubular cross-members of exceptionally large diameter and strongly riveted to the side members serve to minimize frame weaving.

As regards the engine, the six cylinders are in a monobloc casting; this assists greatly in giving rigidity to the unit, as the holdingdown bolts pass right through to the main bearings. The crankshaft has seven main bearings, and the camshaft is mounted in a trough in the cylinder head, being driven by a Duplex roller chain and helical gears, the pinion being split and the parts forced apart by four light springs, whilst the timing chain has a Coventry tensioner—very effective methods of silencing.

Each rocker carries a pin housing a steel ball, upon which is ground a small flat resting upon the valve stem. A. felt pad conveys lubricant to each ball, and the whole valve gear works in oil spray. The whole of the engine oil is by-passed through a thick felt filter every three or four hours of running time.

The change speed control is mounted on the engine-gear-box unit, and is effected by a single sliding and rotating tube which is operated direct by the change-speed lever.

A two-piece propeller shaft with Spicer joints conveys the drive to the underneath worm of the semifloating rear axle, which is a potcasing of nickel steel.

The brake gear can be examined without exposing any bearings, and coppered-steel brake connectors are utilized. The axle ratio is 6.5 to 1, and the pot is close to the near-side wheel, the engine and whole drive line being off-set.

In the front wheels, the brakeoperating rods pass through the hollow stub-axle pins.

Desmo Flexi Lnbri covers are provided for the ball joints of the steering. The Marles cam-androller steering gear is now employed. It is rather interesting to mention that all buyers of Titan buses, with the exception of two, ordered standard complete buses without any modifications in equipment, etc., and over 60 per cent. are already repeat orders. A much-appreciated feature is the batteries of lubricators, these being congregated at three points, with the exception of two nipples in the back axle, which are accessible through the floor.

The suspension of the Titan chassis leaves little to be desired, for the total movement of the front and rear springs is 6 ins. and 9 ins. respectively. Noise is often caused by sideplay on spring shackles, but in this chassis provision is made to permit the taking up of wear.