MAKING BEST USE OF THE FORD.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

IN THIS series of hints concerning the Ford light chassis and, ton truck wherever they are employed for commercial purposes, we endeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer, or mechanic. Valuable sources of information are being tapped for this purpose', and it should be understood that the advice given will be derived from those with an intimate knowledge of the subject. , We shall welcome for inclusion among the hints those which have proved of value-to individual users, and will make suitable remuneration for any pub

fished. What we desire are the results of practice.

125.—Saving Wear on the Commutator.

Filling the commutator casing with clean thin grease is a remedy against exceseive wear, given by a Ford driver, who states that he has followed this practice for a long time without any trouble occurring. It saves the wear on 'the rollers and obviates the need for oiling every day ; as a matter of fadt, the grease lasts three to four months before requiring renewal.

brivers may give this method a trial, although we are afraid that it would fail in,some instances, particularly where the magneto current is at all weak. However, in such cases, it would not be difficult to .wash out the grease and to follow the more ordinary procedure.

126.—Getting Home with a Broken Hub.

A trouble sometimes experienced with the Ford is breakage of the inner flange of the hub cap. The first symptom of this is sudden racing of the engine, similar to that which occurs when an axle shaft breaks, and the, vehicle, of course, comes to a standstill.

If the engine be left running in gear for a short time, it will he seen that the hub cap is revolving, although the wheel remains stationary, and on taking the wheel off it will be found that the inner flange is completely separated from the hub. It is quite possible that it may have been cracked for some time, and, with the snatching of the drive it has finally broken loose. It may even have smoothed down the irregularities round the crack which might for some time have acted in the same capacity as driving dogs.

A dangerous feature of this particular trouble is that there is nothing to prevent the wheel coming off, which almost always happens if the vehicle be travelling at any considerable speed.

MO Should this trouble occur. a long way from home or a garage, it care be patched Up in the manner, shown.

To effect this, unscrew the nut at the end of the axle shaft which, normally, secures the 'hub in position, and put the hub-cap spanner on to the threaded end, using one of the, inner hexagon holes. Next screw the nut back until, it grips the spanner tightly,, then put twO pieces of wood packing between the back of the spanner and the outer flange of the wheel; This prevents end movement of the last-named.

The spanner must now be wired to the" spokes in such a manner that it can transmit the drive. In the case of the left-hand wheel, the nut should be particularly tight as it has a tendency to, unscrew as the spanner takes up the drive.

127.—A Ford Engine as a StatiOnary Power Plant.

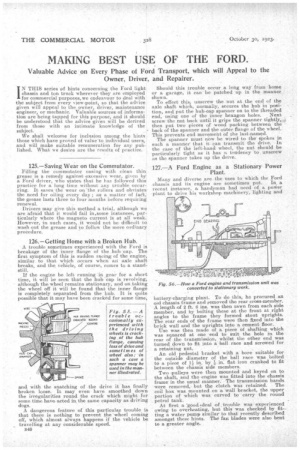

Many and diverse are the uses to which the Ford chassis and its engine are sometimes put. In a recent instance, a handyman had need of a power plant to drive his workshop machinery., -lighting and

battery-charging plant. To do this, he procured an old chassis frame and removed the rear cross-member. A length of 2 ft. 6 ins, was then sawn from each side member, and by bolting these at the front at right angles to the frame they formed stout uprights. The rear ends of the frame were then fixed into the brick wall and the uprights into a cement floor. Use was then made of a piece of shafting which was squared at one end to suit the hole in the rear of the transmission, whilst the other end was turned down to fit into a' hall race and screwed for a retaining nut. An old pedestal bracket with a bore suitable for the outside diameter of the ball race was bolted to a piece of 11 in. by 1. in: flat iron cranked to fit between the chassis side members.

Two pulleys were then mounted and keyed on to the shaft, and the engine was fitted into the chassis frame in the usual manner. The transmission bands were removed, but the clutch was retained. The coil box was mounted on a 'wall bracket, the upper portion of which was curved to 'carry the round petrol tank. At first a good .deal of ,trouble was experienced owing to overheating, but this was checked by fit-ting a water pump similar to that recently described amongst these hints. The fan blades were also bent to a greater angle.