AN ENGINE WITHOUT CRANKS.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

A Fuller Description of the Michell Engine with Its Novel Lubricating System.

IN the history of engineering endeavour many otherwise clever efforts have failed by reason of defects in the lubricating systeindefects which have been difficult or impossible to. overcome in the time available before funds or interest had waned. The experience gained during the war with the Michell bearing used as a thrust bearing on propeller shafts has shown that it must. be of value in other positions where friction must be overcome, yet where the load on the necessary lubricating film must be high.

Engines have been developed and tried at the. request of the Air Ministry, Rolls-Royce, Ltd., being. the makers; in which the awash-plate is employed, the pistonsexerting their pressure on. the disc through Michell pads. Other millti-cylinder engines on the same lines have been built and excellent, results have been obtained. We have now had an opportunity of inspecting one of these engines at work and have found it most interesting, so much so that we thought a more detailed deseription_of the ,corn

ponent parts and their functions would appeal to our readers. We gave a brief description of the general arrangement of the engine in our last tissue and are now able to. go more fully into the details.

Not only is the Michell engine crank less, but, other components of the petrol motor usually considered necessary are dispensed with, as there is neither flywheel, connecting rod nor gudgeon pin. The taking up of big-ends is never necessary, because there are no big-ends to take up. Any slackness of contact

between the awash-plate and the eight pads is, by contrast, a matter of simple adjustment.

A perfect harmonic balance of all moving parts is obtained, which is not possible when cranks and connecting rods have to be employed, unless complicated and costly additions are made to an engine. One fact that strikes one forcibly is that no forces act at right angles to the main shaft. Then, again, any number of cylinders (within certain limits) can be used without adding to the cost. or complication of what takes the place of the crankshaft.

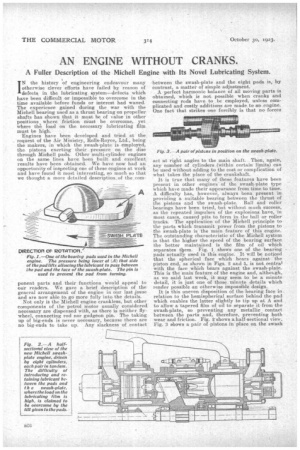

It is true that many of these features have been present in other engines of the awash-plate type which have made their appearance from time to time. A difficulty has,, however, always been present in providing a suitable bearing between the thrust of the pistons and the awash-plate. Ball and roller hearings have been tried, but without much success, as the repeated impulses of the explosions have in most cases, caused pits to form in the ball or roller tracks. The application of the Michell principle to the parts which transmit power from the pistons to the awash-plate is the main feature of this engine. The outstanding characteristic of the Michell system is that the higher the speed of the bearing surface the better maintained is the film of oil which separates tem. Fig. I. shows one of the bearing pads actually used in this engine. It will be noticed that the spherical face which bears against the piston end, as shown in Figs. 2 and 5, is not central with the face which bears against the awash-plate. This is the main feature of the engine and, although, as we said last week, it may seem to be a minute detail, it is just one of those minute details which render possible an otherwise impossible design.

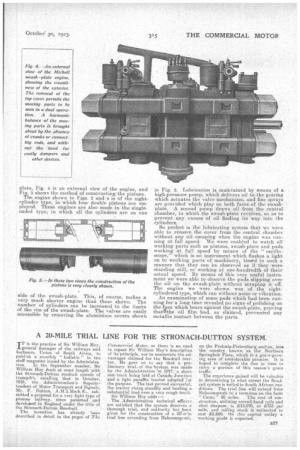

It is this uneven disposition of the bearing face in relation to the hemispherical surface behind the pad which enables the latter slightly to tip up at A and to allow a tapered film of oil to separate it from the swash-plate, so preventing any metallic contact between the parts and, therefore, preventing both wear and friction. Fig. 2 shows a half-sectional view, Fig. 3 shows a pair of pistons in place on the awash Plate, Fig. 4 is an external view of the engine, and Fig. 5 shows the method of constructing the pistons.

The engine shown in Figs. 2 and 4 is of the eightcylinder type, in which four double pistons are employed. These engines are also niade in the singleended type; in Which all the cylinders are on one side of the swash-plate. This of course; makes a very much shorter engine than those shown. The number of cylinders can be inereasnd to the limits of the rim of the swash-plate. The valves are easily accessible by removing the aluminium covers shown

in Fig. 2. Lubrication is maintained by means of a high-pressure pump, which delivers oil to the gearing which actuates the valve mechanism, and fine sprays are previded which play on both faces of the swashplate. • A second pump draws oil from the central chamber, in which the swash-plate revolves, so as to prevent any excessof oil finding its way into the cylinders. So perfect is the lubricating system that we were able to remove the cover from the central chamber without any oil escaping when the engine was running at full speed. We were enabled to watch all working parts such as pistons, awash-plate and pads working at full speed by means of the "oscilloscope," which is. art instrument which flashes a light on to working parts of machinery, timed in such a manner that they can be observed as if -they were standing still, or working at one-hundredth of their actual speed. By means of this very useful instrument we were able to observe the pads slipping over the oil on the awash-plate without scraPing it off. The engine we were shown was of the eighteylindered type, which ran without noise or vibration.

An examination of some pads which had been running for a long time revealed no signs of polishing on the Tace which bears against the swash-plate, proving thatSthe oil film had, as claimed, prevented any metallic contact between the parts.