A New German Oil Engine of high efficiency

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

THE Magirus company of Ulm/ Donau, Germany, which has for many years built petrol engines for its various lorries, buses and fireengines, has now introduced a range of entirely new pre-combustion-chamber oil engines of extremely interesting design. In respect of weight, torque, and power output, these engines are comparable with the latest products of other manufacturers of greater oil-engine experience. Three models are now in production—a 3-litre four-cylindered unit, developing 45 b.h.p. at 2,200 r.p.m., a six-cylindered engine of 4.5 litres piston displacement, with an output of 65 b.h.p. at 2,000 r.p.m., and a 110 b.h.p. unit, of which particulars are not yet available.

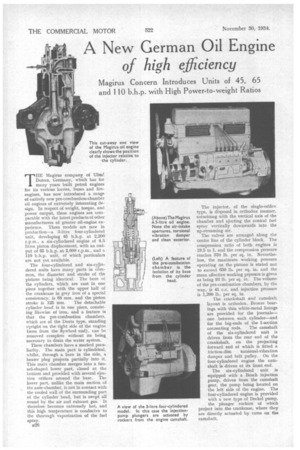

The four-cylindered and six-cylindered units have many parts in common, the diameter and stroke of the pistons being identical. The bore of the cylinders, which are cast in one piece together with the upper half of the crankcase in grey iron of a special consistency, is 88 mm. and the piston stroke is 125 ram. The detachable cylinder head is in one piece, consisting likewise of iron, and a feature is that the pre-combustion chambers, which are of the Deutz type, standing upright on the right side of the engine (seen from the flywheel end), can be removed complete without its being necessary to drain the water system.

These chambers have a marked peculiarity. The main part is cylindrical, whilst, through a bore in the side, a heater plug projects partially into it. This main chamber merges into a funnel-shaped lower part, closed at the bottom and provided with several ejection orifices around the base. The lower part, unlike the main section of the ante-chamber, is not in contact with the cooled wall of the surrounding part of the cylinder head, but is swept all round by the air and exhaust gas. It therefore becomes extremely hot, and this high temperature is conducive to the thorough vaporization of the fuel spray.

B26 The injector, of the single-orifice type, is disposed in orthodox manner, coinciding with the vertical axis of the chamber and ejecting the conical fuel spray vertically downwards into the up-streaming air.

The valves are arranged along the centre line of the cylinder block. The compression ratio of both engines is 19.5 to 1, and the compression pressure reaches 570 lb. per sq. in. Nevertheless, the maximum working pressure operating on the pistons is stated not to exceed 650 lb. per sq. in, and the mean. effective working pressure is given as being 93 lb. per sq. in. The volume of the pre-combustion chambers, by the way, is 41 c.c. and injection pressure is 1,200 lb. per sq. in.

The crankshaft and camshaft layout is orthodox. Bronze bearings with thin white-metal linings are provided for the journals— one between each cylinder—and for the big-ends of the I-section connecting rods. The camshaft of the six-cylindered unit is driven from the rear end of the crankshaft, on the projecting forward end of which is fitted a

friction-disc torsional-vibration damper and belt pulley. On the four-cylindered engine the camshaft is driven at its front end.

The six-cylindered unit is equipped with a Bosch injection pump, driven from the camshaft gear, the pump being located on the left side of the engine. The four-eylindered engine is provided with a new type of Deckel pump, the plunger rockers of which project into the crankcase, where they are directly actuated by cams on the camshaft.

The lubrication pump is of the gear ype, and is driven by means of skew gear and a 'vertical shaft from the camshaft at the rear end of the engine. As the sump is a steel pressing, the pump is attached to the upper part cf he crankcase. Oil is drawn into toe pump through the usual strainer and thence passes to a Bosch fabric filter located above the flywheel casing. From this filter, which is provided with a by-pass relief valve, oil is fed through distribution pipes to the main bearings, whence it reaches, through bored passages, the big-end journals and the camshaft bearings.

A secondary line leads up t6 the shaft en the cylinder head carrying the lockers so as to lubricate their bear, ings and the valve stems. The sump holds slightly more than seven litres. The inlet-valve ports open into free spaces inside the eylinder-head casting, which has two long and rectangular orifices on the left side covered with copper-wool filters moistened with oil. The exhaust ports open on the opposite side.

Made of Elektron Y-alloy, the pistons weigh, complete withgudgeon pin and four rings, 2.17 lb. each. Their length is 115 mm., so that, in consideration of the bbre of only 88 mm., a more than adequate bearing surface is afforded. Each connecting rod measures, between centres, 263 mm. in the fourcylinciered unit, and 253.5 min; in the six-cylindered engine, and the weights with bearings are 5.128 lb. in the former CaSe 'and 3.75 lb. in the 'latter.

Weighing 727 lb. complete, the fourcylindered engine thus has an output

of 16.15 b.h.p. for every lb. weight and of 14.8 b.h.p. for every litre of piston displacement. The latter ratio is said to be the highest for any.German highspeed four-stroke-cycle oil engine.

The six-cylinderedengine weighs 968 lb. or 14.9 lb. per b.h.p., and develops 14.2 b.h.p.per litre, which is likewise a very good -figure. The larger unit develops & torque of 188 lhaft. at 800 r.p.m., which gradually drops to

173 lb.-ft. at 2,000 r.p.m. .

A centrifugal water pump is mounted on the front of the cylinder .block. There is a thermostat inside the upper water connection. To facilitate starting, the' rockers are eccentrically mounted on their support shaft, which can be turned through 90 degrees, from the cab, thus relieving cylinder pressure.