REFINEMENTS ON SIX-WHEELED BUSES.

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

For the Reduction of Vehicle Vibration and for Cutting Down Costs of Maintenance New Devices are Adopted.

IT will be remembered that the Salford Corporation Tramways Department has. recently ordered from Karrier Motors, Ltd., certain chassis of the 1NL6 model, being six-wheelers with rigid frames. These are being employed in the bus services of the corporation and are evidently intended to be operated over routes which are rough and where a certain amount of dust is likely to be experienced, for they are being fitted with the Westinghouse air springs and the Protectomotor airfiltering device on the air intake to each carburetter.

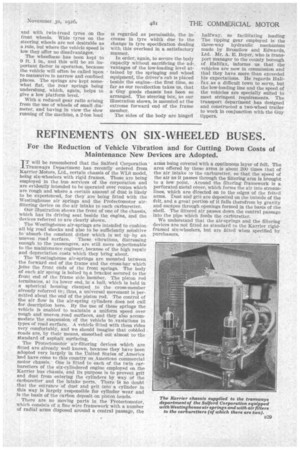

Our illustration shows the front of one of the chassis, which has its driving seat beside the engine, and the devices referred to are clearly shown.

The Westinghouse air-springs are intended to cushion all big road shocks and also to be sufficiently sensitive to absorb the constant dither which is set up by an uneven road surface. These vibrations, distressing enough to the passengers, are still more objectionable to the maintenance engineer, because of the high repair and depreciation costs which they bring about.

The Westinghouse air-springs are mounted between the forward end of the frame and the cross-bar which joins the front ends of the front springs. The body of each air spring is bolted to a bracket secured to the front end of the frame side Member. The piston rod terminates, at its lower end, in a ball, which is held in a spherical housing clamped to the cross-member already referred to; thus, a universal movement is permitted about the end of the piston rod. The control of the air flow in the air-spring cylinders does not call for description here. By the use of these springs the vehicle is enabled to maintain a uniform speed over rough and uneven road surfaces, and they also accommodate the suspension of the vehicle to variations in types of road surface. A vehicle fitted with them rides very comfortably, and we should Imagine that cobbled roads are, by their means, smoothed out almost to the standard of asphalt surfacing.

The Protectomotor air-filtering devices which are fitted are already well known, because they have been adopted very largely in the United States of America and have come to this country on American commercial motor chassis. One is fitted to each of the twin carburetters of the six-cylindered engine employed on the Karrier bus chassis, and its purpose is to prevent grit and dust from entering the cylinders by way of the carburetter and the intake ports. There IS no doubt that the entrance of dust and grit into a cylinder in this way is largely responsible for cylinder wear and is the basis of the carbon deposit on piston heads.

There are no moving parts in the Protectomotor, which consists of a fine wire framework with a number of radial arms disposed around a central passage, the arms being covered with a continuous layer of felt. The area offered by these arms is about 200 times that of the air intake to the carburetter, so that the speed of the air as it passes through the filtering arm is brought to a low point. Around the filtering framework is a, perforated Metal cover, which forms the air into streamlines, which are directed on to the edges of the felted arms. Dust and grit are deposited on the 'outside of the felt, and a great portion of it falls therefrom by gravity and escapes through openings formed in the basis of the shell. The filtered air passes down the central passage into the pipe which feeds the carburetter.

We understand that the air-springs and the filtering devices are not fitted as standard to the Karrier rigidframed six-wheelers, but are fitted when specified by p irchasers.