Mixed Fleo referred for Quarrying Work

Page 62

Page 63

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

LARGE-SCALE haulage of quarried stone and associated products is a searching test of tipping vehicles, and of the skill of their operators. The tipper has to contend with more than the normal portion of off-the-road work, with the attendant stress on chassis and bodywork, and the load is of an abrasive character.

Economic use of the fleet is difficult because Of the wide and rapid fluctuations in traffic brought about by changes in the weather and other factors. These, and many more problems, are the daily lot of Hobbs (Quarries), Ltd., Flax Bourton, Somerset, and the eminently down-to-earth views of Mr. A. Robert Hobbs, managing director, on the subject of quarry transport are worth recording.

This company operate on a fairly large scale, their headquarters and main source of supply being the two-year-old Stancombe Quarry, situated at Flax Bourton, four miles from the Bristol city boundary. Other quarries are being worked by the company and associates at sites near Thornbury, Caerphilly and Pyle, Bridgend.

The delivery zone extends over Gloucestershire, Glamorganshire, Oxfordshire, Berkshire and Somerset. Limestone products of all kinds are marketed, including concreting aggregates, roadstone, macadam, asphalt, agricultural dust and filler dust. Road c24 construction work is undertaken, and there is a limespreading department, as well as a separate works making Concrete, mortar and lime.

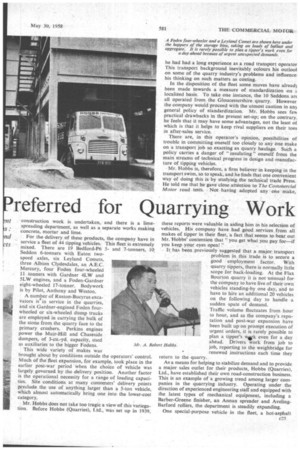

For the delivery of these products, the company have in service a fleet of 44 tipping vehicles. This fleet is extremely mixed. There are 19 Bedford-P6 5and 7-tonners, 10, Seddon 6-tonners with Eaton twospeed axles, six Leyland Comets, three Albion Clydesdales, an A.E.C. Mercury, four Foden four-wheeled 11 tonners with Gardner 4LW and 5LW engines, and a Foden-Gardner eight-wheeled 17-tonner. Bodywork is by Pilot, Anthony and Weston.

A number of Rustorr-Bucyrus excavators is in service in the quarries, and six Gardner-engined Foden fourwheeled or six-wheeled dump trucks are employed in carrying the bulk of the stone from the quarry face to the primary crushers. Perkins engines power the Muir-Hill and Chaseside dumpers, of 3-cu.-yd. capacity, used as auxiliaries to the bigger Fodens.

This wide variety of makes was brought about by conditions outside the operators' control. Much of the-fleet expansion, for example, took place in the earlier post-war period when the choice of vehicle was largely governed by the delivery position. Another factor is the operational necessity for a range of loading capacities. Site conditions at many customers' delivery points preclude the use of anything larger than a 5-ton vehicle, which almost automatically bring one into the lower-cost category.

Mr. Hobbs does not take too tragic a view of this variegation. Before Hobbs (Quarries), Ltd., was -set up in 1939,

he had had a long experience as a road transport operator This transport background inevitably colours his outlool on some of the quarry industry's problems and influence: his thinking on such matters as costing.

In the disposition of the fleet some moves have alread3 been made towards a measure of standardization on E localized basis. To take one instance, the 10 Seddons arc all operated from the Gloucestershire quarry. However the company would proceed with the utmost caution in any general policy of standardization. Mr. Hobbs sees few practical drawbacks in the present set-up; on the contrary, he feels that it may have some advantages, not the least of which is that it helps to keep rival suppliers on their toes in after-sales service.

There are, in this operator's opinion, possibilities of trouble in committing oneself too closely to any one make on a transport job so exacting as quarry haulage. Such a policy carries a danger, of " insulating " oneself from the main streams of technical progress in design and manufacture of tipping vehicles.

Mr. Hobbs is, therefore, a firm believer in keeping in the transport swim, so to speak, and he finds that one convenient way of doing this is by studying the technical trade Press.

He told me that he gave close attention to The Commercial Motor road tests. Not having adopted any one make, these reports were valuable in aiding him in his selection of vehicles. His company have had good services from all makes of tipper in their fleet, a fact that seems to bear out Mr. -Hobbs' contention that "you get what you pay for—if you keep your eyes open!"

It has been previously suggested that a major transport problem in this trade is to secure a good employment factor. With quarry tippers, there is normally little scope for back-loading. At the Flax Bourton quarry it is not unusualfor the company to have five of their own vehicles standing-by one day, and to have to hire an additional 20 vehicles on the following day to handle a sudden spate of demand.

Traffic volume fluctuates from hour to hour, and as the company's reputation and post-war expansion have been built up on prompt execution of urgent orders, it is rarely possible to plan a tipper's work even for a day ahead. Drivers work from job to job, reporting to the weighbridge for renewed instructions each time they return to the quarry.

As a means for helping to stabilize demand and to provide a major sales outlet for their products, Hobbs (Quarries), Ltd., have established their own road-construction business. This is an example of a growing trend among larger companies in the quarrying industry. Operating under the direction of experienced engineering staff and equipped with the latest types of mechanical equipment, including a Barber-Greene finisher, an Annan spreader and AvelingBarford rollers, the department is steadily expanding.

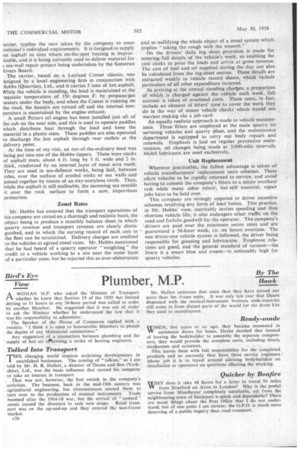

One special-purpose vehicle in the fleet, a hot-asphalt c25 :arrier, typifies the care taken by the company to meet :ustorner's individual requirements. It is designed to supply tot asphalt to sites where' on-the-spot heating is impracicable, and it is being currently used to deliver material for sea-wall repair project being undertaken by the .Somerset tiverstOard.

. The carrier, based on a Leyland Comet chassis, was Jesigned by a local engineering firm in .conjunction with 4obbs (Quarries), Ltd., and it carries 5 ton S of hot asphalt. While the vehicle is standing, the load is maintained at the -equisite temperature of 350 degrees F. by propane-gas waters under the body, and when the Comet is running on the road, the heaters are turned off and the, internal tern-, perature .is maintained by the engine exhaust.

. A small Petters oil engine has been installed just aft of the cab on the near side, and this is used to operate paddles which: distribute heat through the load and keep the material in a plastic state. These paddles are also operated to discharge the hot asphalt through rear outlets at the delivery point, At the time of my visit, an out-of-the-ordinary load was being put into one of the Hobbs tippers. . These were stacks of asphalt mats, about 6 ft. long by 3 ft. wide and 2 in. thick, reinforced by an internal .layer of stout wire mesh. They are used in sea-defence works, being laid, between tides, over the surface of eroded rocks or sea walls and joined together by means of an oxy-acetylene torch. Then, while the asphalt is still malleable, the incoming sea moulds it over the rock surface to form a new, impervious protection.

Zonal Rates

Mr. Hobbs has ensured that the transport operations of his company are costed on a thorough and realistic basis, the object being to produce a monthly balance sheet.in which quarry revenue and transport revenue are clearly distinguished, and in which the earning record of each, unit in the fleet can be scrutinized. Delivery charges are credited to the vehicles at agreed zonal rates. Mr. Hobbs mentioned that he had heard of a quarry operator " weighting " the credit to a vehicle working to a site near the outer limit of a particular zone, but he rejected this as over-elaboration and as nullifying the whole object of a zonal system which implies " taking the rough with the smooth." On the drivers' daily log sheet provision is made for entering full details of the vehicle's work, so enabling the cost clerks to price the loads and arrive at gross revenue. The cost of fuel and oil supplied during the day can" also be calculated from the log-sheet entries. These details are extracted weekly to vehicle record sheets, which include particulars of all other expenditure incurred.

In arriving at the annual standing charges, a proportion of which is charged against the vehicle each week, full account is taken of overhead costs. These costs, in fact, include an element of fitters' time to cover the work they do in the way of minor vehicle checks which would not warrant making alit a job card. ,

An equally realistic approach-is made to vehicle maintenance. Three fitters are employed at the main quarry on servicing vehicles and quarry plant, and the maintenance department is equipped to carry out body repairs and renewals. Emphasis is laid on regular preventive maintenance, oil changes 'being made at 3,000-mile intervals. Mobil lubricants are used exclusively.

Unit Replacement

Wherever practicable, the fullest advantage is taken of vehicle manufacturers' replacement units schemes. These allow vehicles to be rapidly returned to service, and avoid having to commit the company's fitters to a major overhaul task while many other minor, but still essential, repair jobs have to be held over.

This company are strongly opposed to driver incentive schemes involving any form of load bonus. This practice, in Mr. Hobbs' view, inevitably invites speeding and thus shortens vehicle life; it also endangers other traffic on the road and forfeits goodwill for the operator. The company's drivers are paid over the minimum union rates and are guaranteed a 50-hour week, i.e. six hours overtime. The one driver-one vehicle system is followed, the driver being responsible for greasing and lubrication. Employee relations are good, and the general standard of turnout—the livery is a smart blue and cream—is noticeably high for quarry vehicles.