HINTS ON MAINTENANCE.

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle. to Secure Reliability and to Avoid Trouble

CONTRIBUTIONS are invited for this pagefrom fleet managers, drivers, garage foremen, and mechanics, works staff and draughtshien, and will be paid for on a generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, dealing with letters from our driver and mechanic readers. Communications should be addressed, to " The Editor, The Commercial Motor, 7-15, Rosebery Avenue, London, E.C.1."

212.—Notes on Springing and a Leyland Modification.

Insufficient attention is usually paid to the lubrication of road springs and shackle bolts, and a broken top leaf can often he put down to a seized shackle pin.

Occasionally insufficient. clearance is left in the shackle pin bushes. Most of the shackle pins are fitted With greasers, and .005 in. clearance is none too much to allow. If the clearance is insufficient, it is almost, impossible to force grease between the bush and pin, with the result that seizures are very likely to occur.

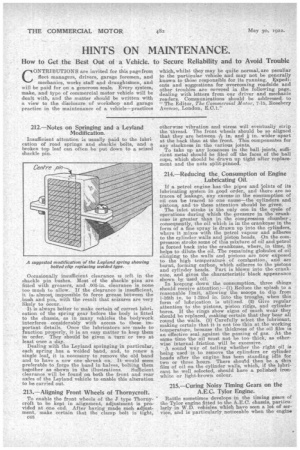

It is always better to make certain of correct lubrication of the spring gear before the body is fitted to the chassis, as in many vehicles the bodywork interferes considerably with access to these important details. Once the lubricators are made to function properly, it is an easy matter to keep them in order. They should be given a turn or two at least once a day. Dealing with the Leyland springing in particular, each spring has a welded band, and, to renew a single leaf, it is necessary to remove the old band and to have a new one slirunk on. It would seem preferable to forge the band in halves, bolting them together as shown in the illustrations. Sufficient clearance will be found on both the front and rear axles of the Leyland vehicle to enable this alteration to be carried out.

213.—Aligning Front Wheels of Thornycroft.

To enable the front wheels of the J type Thornycroft to be kept in alignment, adjustment is provided at one end. After having made such adjustment, make certain that the clamp bolt is tight, c48 otherwise vibration and stress will eventually strip the 'thread. The front wheels should be so aligned that they are between in. and I in. wider 'apart at the back than at the front. This compensates for any slackness in the various joints. To take up any looseness in the ball joints sufficient metal should be filed off the faces of the ball cups, which should be drawn up tight after replacement and the nuts split-pinned.

214.—Reducing the Consumption of Engine Lubricating Oil.

If a petrol engine has -the pipes and loints of its lubricating system in gogd order, and there are no traces of leakage, any excess p in the consumption of oil can be traced to one cause—the cylinders and pistons1 and to these attention should be given.

The inlet stroke is the only one in the cycle of operations during which the pressure in the crankcase is greater than in the compression chamber ; consequently, the oil which is in the crankcase in the form of a fine spray is drawn up into the cylinders, where it Mixes with the petrol vapour and adheres to the cylinder walls and piston heads. On the compression stroke some of this mixture of oil and petrol is forced back into the crankcase, where, in time, it helps to dilute the oil. The remaining globules of oil clinging to the walls and pistons are now exposed to the high temperature of combustion, and are burnt, forming carbon, 'which adheres to the pistons and cylinder heads. Part is blown into the crankcase, and gives the characteristic blackappearance shown by used oil. In keeping down the consumption, three things should receive attention :—(1) Reduce the splash to a. reasonable limit, allowing the scoops to dip from 1-16th in. to 1-32nd in. into the troughs, when this form of lubrication is utilized. (2) Give regular attention to the pistons, piston rings, and cylinder bores. If the rings Show signs of much wear they should be replaced, making certain that they bear all round the wails. (3) Carefully select the lubricant, making certain that it is not too thin at the working temperature, because the thickness of the oil film is an effective seal against the passing of gas. At the same time the oil must not be too thick, as otherwise internal friction will be excessive. A sound way of telling whether the right oil is being used is to remove the cylinders or cylinder heads after the engine has been standing idle for two or three hours. There should then be a thin film of oil on the cylinder walls, which, if the lubricant be well selected, should have a polished ironwhite or light-brown colour.

215.—Curing Noisy Timing Gears on the A.E.C. Tylor Engine.

Rattle sometimes develops in the timing gears of the Tyler engine fitted to the A.E.C. chassis, particularly in W.D. vehicles which have seen a lot of service, and is particularly. noticeable when the engin•

is "ticking over," thus indicating wear of teeth and consequent "backlash."

Before doing anything at all to the engine, a new phosphor-bronze intermediate timing gear should be procured. It is in this wheel that trouble has developed, and it is certain that a new one will be required. Subsequently, when the gears are examined, it will be found that this intermediate wheel is either badly worn as to the teeth, is loose on its pressed-in bush., or has worn in the bush. Backlash will be one result, whatever the cause, but if the last-named is the sourceof the trouble, difficulties with the engine lubrication will also ensue, due to the escape of too much oil through this bush. This is due to the fact that the spindle on which this bush revolves is, in common with the majority of the engine bearings, fed with oil under pressure from the pump. If the bush is loose, too large a quantity of lubricant will pass, flooding the timing case and finding its way, as records a considerable percentage of it, outside the engine via the crankshaft gland. Having procured the new gearwheel, the backlash should be tested. Do this before starting to dismantle the engine. Grip the magneto driving dog with a suitable spanner and rock it to and fro within the limits of the play allowed by this wear. Incidentally, look out for end play of this shaft, and, should any be noted, take it up at once by placing a sheetmetal washer between the ball-thrust washer and the bronze hush at the water pump end of the shaft. This bush may be withdrawn by the removal of its• securing setscrew, which is visible immediately above it on the outside of the engine casing.

As a preliminary to dismantling the timing ease cover, the radiator should be removed: When the cover is off and the gears exposed to view proceed at once to withdraw the intermecnate wheel. It is not necessary to disturb 8ither camshaft or crankshaft wheels to get this one away, as a slight twisting movement a,,s it is being withdrawn will suffice to allow the helical teeth to slide past one another.