Feed Pumps.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Contributed by an Engineer-in-Charge.

Builders of steam wagons are beginning to realise the importance of fitting a pump and injector instead of two injectors, as it is not uncommon to find both injectors out of action from various causes; they require special care in their manipulation, and, coupled with the fact that their working is less understood by the majority of men driving steam wagons, less trouble is usually experienced in the event of anything going wrong when a pump is fitted. Without depreciating the value of injectors, the disadvantages they possess, when compared with pumps, are :

their liability to refuse to work with dirty water or when any foreign substance passes into it, or the injector or water becoming too hot; (2) the inability to regulate them according to the amount of steam the engine is using—it becomes necessary to inject a lot of cold water in the boiler at times, the pressure falling on account of this; (3) if the pressure in the boiler gets too low the injector will not pick it up. The advantage that an injector possesses over a pump, is, that water can be fed into the boiler while the wagon is standing without running the engine. An independent steam pump overcomes this difficulty, and, from my experience, this is the best pump for steam wagons or tractors, if properly fixed and in the hands of a careful man.

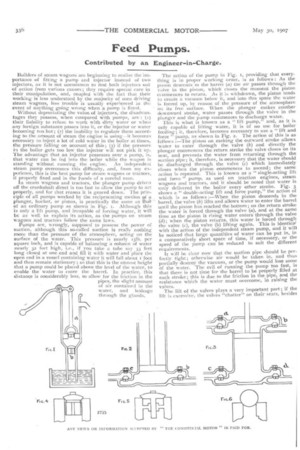

In steam wagons and tractors, the plunger pump driven off the crankshaft direct is too fast to allow the pump to act properly, and for that reason it is geared down. The principle of all pumps worked by the reciprocating motion at a plunger, bucket, or piston, is practically the same as that of an ordinary pump as shown in Fig. i. Although this is only a lift pump, and incapable of forcing water, it will be as well to explain its action, as the pumps on steam wagons and tractors follow the same laws.

Pumps are, wrongly, supposed to possess the power of suction, although this so-called suction is really nothing more than the pressure of the atmosphere, acting on the surface of the water. This pressure is nearly islb. per square inch, and is capable of balancing a column of water nearly 32 feet high, i.e., if you take a tube say 33 feet long dosed at one end and fill it with water and place the open end in a vessel containing water it will fall about Ofoot and then remain stationary; so that this is the utmost height that a pump could be placed above the level of the water, to enable the water to enter the barrel. In practice, this distance is considerably less, to allow for the friction in the pipes, the slight amount of air contained in the water, and leakage through the glands. The action of the pump in Fig. a providing that everything is in proper working oruer, is as follows : As the piston descends in the barrel (a) the air passes through the valve in the piston, which closes the moment the piston commences to return. As it is withdrawn, the piston tends to create a vacuum below it, and into this space the water is forced up, by reason of the pressure of the atmosphere oa its free surface. When the plunger makes another downward stroke, water passes through the valve in the plunger and the pump commences to discharge water. This is what is known as a " lift pump,'' and, as it is only capable of lifting water, it is of no use for boiler feeding; it, therefore, becomes necessary to use a " lift and force " pump, as shown in Fig. 2. The action of this is as follows :—The piston on making the outward stroke allows -water to enter through the valve (b) and directly the plunger commences the return stroke the valve closes on its seat, and prevents the water from returning through the suction. pipe; it, therefore, is necessary that the water should be discharged through the valve (c) which immediately closes when the piston commences to ascend; the same action is repeated. This is known as a " single-acting lift and force " pump, as used on traction engines, steam wagons and tractors, and it should be noted that water is only delivered in the boiler every other stroke. Fig. 3 shows a " double-acting lift and force pump," the action of which is as follows :—When the piston descends in the barrel, the valve (b) lifts and allows water to enter the barrel until the piston has reached the bottom; on the return stroke the water is forced through the valve (a), and at the same time as the piston is rising water enters through the valve (d) ; when the piston returns, this water is forced through the valve (c), the valve (b) lifting again. This is identica; with the action of the independent steam pump, and it will be noticed that large quantities of water can be put in, in a comparatively short space of time, if necessary, or the speed of the pump can be reduced to suit the different requirements.

It will be clear now that the suction pipe should be perfectly tight; otherwise air would be taken in, and thus partially destroy the vacuum, or the pump would lose some of the water. The evil of running the pump too fast, is that there is not time for the barrel to be properly filled at each stroke; this is due to the friction in the pipe, and the resistance which the water must overcome, in raising the valves. The lift of the valves plays a very important part; if the lift is excessive, the valves "chatter" on their seats, besides

hammering the faces on both valve and seat, and destroyingthem; but, on the other hand, if the lift is not enough, me water meets with increased resistance through the area being restricted. It is found in practice that about onefourth the diameter of the valve is the most suitable lift ; i.e., a valve i inch in diameter should lift -4.inch, and, as the valve and face wears down through repeated grinding, the stop above the valve, to prevent it lifting out, must be lengthened to keep the right lift. Valves are usually made as shown in Figs. 4, 5, and 6. Fig. 4 shows a " wing valve," where three wings are leit on the valve, and turned over the tops; these are a free ti in the casting, and act as guides for the valve; if these art too slack, they might permit the valve to cross-bind, or, if too tight, would offer too much resistance to the water. A " mushroom " valve is shown in Fig.. 5, the stem being turned a free fit in the bridge piece across the valve box, which should also he bored to suit it. The " ball " valve, shown in Fig. 6, is a gun-metal ball very accurately turned, which acts in the same way as the ordinary mushroom valve; owing to the motion of the water through the valve box, the ball is continually changing its position and does not have a ridge worn on it by continually seating in one position. The seats are usually turned at an angle of 15 degrees, with faces i-i6th of an inch wide, and any time the valve shows signs of leakage, it should be slightly ground in with a little flour emery and oil, perfectly free from grit, and carefully wiped out after; if any emery or grit is left on, the working of the valve will rapidly destroy the faces.

The ends of the suction pipes must be fitted with a thoroughly -efficient strainer, to prevent any foreign substance getting into the pipe, and finding its way to the valves; this would probably lodge in the seats, and prevent the pump from working. In steam wagons and tractors, it is of the utmost importance that the strainer should be easily accessible for the purpose of cleaning, on account of the mud, and dirt in the tank, which is always in suspension; it should never be smaller n diameter than the diameter of the suction branch provided on the pump by the maker : this is usually larger than the delivery pipe. All sharp bends should be avoided, in order to reduce the friction as much as possible.

If at any time the pump refuses to work, the first thing to do is to examine the valves (if the pump is not hot) to see that nothing has lodged under them, to prevent their resenting, thus allowing the water to be forced back into the tank; if this is so, the valve must be removed and cleaned, and the strainer examined to prevent anything else going through. If the pump is hot, it is most likely that the check valve on the boiler is leaking, either through be ing stuck, or having something underneath it. Unless this. is provided with means of shutting the steam off from the. boiler, it cannot be disconnected, although very often a few light blows from a hand hammer will set it right; great_ care must be used, however, or the, valve box will be cracked. or damaged.

The pump should be provided with a " test cock" on the. barrel, in order to ascertain whether the pump is working properly when running; it should throw a jet of water when. the test cock is opened. The gland packing should be examined from time to time; it should always be kept properly packed with suitable packing, to prevent any air finding its way into the barrel, or allowing the water to escape.. When using the pump continually, it is advisable to test. the injector at least once a day, to make sure it is all right,. otherwise it may be found to be inoperative when required.

It is always worth the small extra expense to have an independent suction pipe fitted to the pump and injector, so that, in the event of one of them going wrong, the other iscapable of being worked until an opportunity occurs to take off the faulty one and clear it; if both are drawing off the same suction pipe, and that becomes choked, it is impossible. to put any more water in the boiler until it has been taken. off and cleared.. Directly anything goes wrong with thefeeds, stop immediately and close the damper to check any rise of steam pressure, and, if any doubt exists as to the quantity of water present in the boiler, smother the fire with coal, ashes, or anything handy, in preference to drawing the, fire, which would, of course, involve a somewhat lengthy and inconvenient stop on the road. Prompt action on the. driver's part avoids considerable delay where the feed-water.system is concerned.