Crosville leads the way in National recovery

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

LEYLAND'SNational single decker could have been the bus for all men if it had not been for that engine. Dissatisfaction with the fixed-head Leyland 510 engine must have lost the National customers and the introduction of the more conventional engined Mark Two did not win them all back.

Changing market conditions too ensured that the National never quite had the impact it deserved. Nevertheless, over 8,000 were built between 1973 and 1984. Most are still in service.

Operators with Mark One Nationals generally agree that structurally the bodies are as sound and as strong as anything on the road. And it is this strength that makes it worth investing in vehicles and refurbishing for a second life a life which should not be beset with problems caused by the original small turbocharged engine.

Several years ago a bus operator described a Leyland National with a Gardner engine

as his ideal bus. That was before the Gardner became a factory option. Since then many Nationals have been converted with their power plant.

With 4,000 or so Nationals in service with National Bus Company subsidiaries the scope for such conversions is considerable, although a one-off project is time consuming and expensive.

National Bus Company subsidiary Crosville has one of the largest Mark One National fleets in the country. It too has a history of, and is a firm believer in, operating buses powered by the almost legendary Gardners. But the fact that 50 so converted Mark Ones are operating in the Crosville fleet indicates that their conversion must be worth considering. Already Os have been sold to Australia.

The conversion package is offered complete with a modified rear floor structure and includes mounting brackets and all necessary supports and bearers. It also includes a new radiator, which remains at the back of the vehicle although the flow through it is reversed in the Gardner application.

Crosville has an added ad vantage in being able to use old Gardner 61-ILXB units removed from life expired Seddon and Bristol single-deckers which have been sold for scrap. These engines are fully reconditioned and offered as part of the conversion package applied to the company's own Nationals. The company feels that the resulting savings in operational costs could make them more economic for many operators than new engines.

The Gardner engine company also sees the re-engining of Nationals as worthy of consideration and has taken an active interest in the project. A Gardner engined vehicle from the Crosville fleet has been carefully evaluated by the engine manufacturer, which is encouraging the conversions.

Crosville now plans to convert most of its remaining National ones to Gardner power. As vehicles with the original engines are sent to the central works for major overhauls they are often slotted into the re-engining programme. What is virtually a production line capable of converting up to three buses a week has been established.

The buses in service are proving reliable and the garages are reporting fuel consumption savings of between 12 and 15 per cent.

Crosville does not quote a set price for the conversion kit; its charges depend on the level of conversion work required. For example, conversion is much more cost-effective for operators already using Gardner engined vehicles and holding spare engines. Nevertheless, it takes company engineers 130 hours to make the parts needed and prepare these for fitting to the bus. The parts include the modified floor structure and underframe components as well as all necessary engine mountings. Full bus conversions take around 280 hours following procedures established by .Crosville engineers.

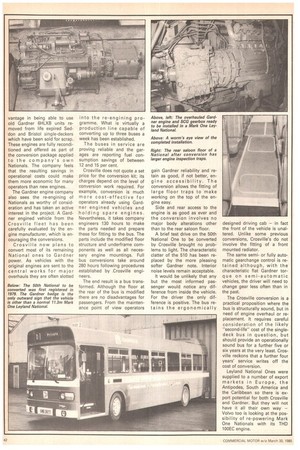

The end result is a bus transformed. Although the floor at the rear of the bus is modified there are no disadvantages for passengers. From the maintenance point of view operators gain Gardner reliability and retain as good, if not better, engine accessibility. The conversion allows the fitting of large floor traps to make working on the top of the engine easy.

Side and rear access to the engine is as good as ever and the conversion involves no major body alterations other than to the rear saloon floor.

A brief test drive on the 50th National One to be converted by Crosville brought no problems to light. The characteristic clatter of the 510 has been replaced by the more pleasing softer Gardner note. Interior noise levels remain acceptable.

It would be unlikely that any but the most informed passenger would notice any difference from inside the vehicle. For the driver the only difference is positive. The bus reta ins the ergonomically designed driving cab — in fact the front of the vehicle is unaltered. Unlike some previous conversions, Crosville's do not involve the fitting of a front mounted radiator.

The same semior fully automatic gearchange control is retained although, with the characteristic flat Gardner torque on semi-automatic vehicles, the driver will need to change gear less often than in the past.

The Crosville conversion is a practical proposition where the bus is structurally sound, but in need of engine overhaul or replacement. It requires careful consideration of the likely "second-life" cost of the singledeck bus in question, but should provide an operationally sound bus for a further five or six years at the very least. Crosville reckons that a further four years' service writes off the cost of conversion.

Leyland National Ones were supplied to a number of export markets in Europe, the Antipodes, South America and the Caribbean so there is export potential for both Crosville and Gardner. But they will not have it all their own way — Volvo too is looking at the possibility of re-powering Mark One Nationals with its THD 100EC engine.