hp. PULLS 2 - 1 TONS UP

Page 62

Page 63

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

1 IN 7

By L. J.

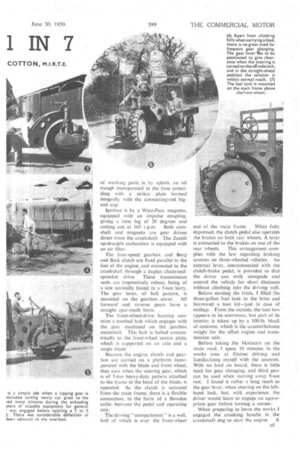

COTTON, M.I.R.T.E. ATHOUGH powered by a small single cylinde red engine, the Opperman Motocart threewheeler has an almost unliniited capacity for hard work. During a one-day trial embodying agricultural and road work, it easily hauled 25-cwt loads across fields and later climbed a 1 in 7. hill, carrying 21 tons of iron castings. Primarily, the Motocart was designed as a replacement for the horsedrawn farm cart, but its performance and usefulness have created for it a wider field in transport, both in this country and overseas.

.Basically., the chassis. has not been altered since the first model was produced, except for providing Springs, for all wheels, which eniphasizeS the soundness of the original design. Many types of body have been fitted to suiL the requirements of municipalities, timber yards and local-delivery operation, and a variety of fixed and tipping bodies is available for agricultural and buildingsite purposes. .

To describe the Motocart as unconventional is almost an understatement. This is not to. say it is unreliable, becausc. a glance at the frame and component construction reveals ability to tackle loads. much greatei than its rated 'capacity. The engine may be small in comparison with . the payload, but governed at a ,Moderate speed and geared to the front wheel through a train of reduction gears, it is far from overworked.

The power unit is a. J.A.P. standard air-cooled petrol engine of .872 c.c. and, governed to 1,700-1,800 r.p.m., it gives a maximum road speed of slightly under 12 m.p.h. This, as well as protecting the unit against misuse and easing the. task of the driver, dispenses with the legal requirement for fitting a speedometer.

The cylinder block, with detachable head, is bolted to the crankcase, which has two roller bearings to support the crankshaft. A fan is attached to the flywheel to assist cooling. Lubrication of working parts is by splash, an oil trough incorporated in the base coinciding with a striker plate formed integrally with the connecting-rod bigend cap.

Ignition is by a Wico-Pacy magneto, equipped. with an impulsecoupling, giving a time lag of 20 degrees and cutting out at 165 r.p.m. Both camshaft and magneto are gear driven direct from the crankshaft. The Zenith up-draught carburetter is equipped with an air filter.

The four-speed gearbox and . Borg and Beek clutch are fixed parallel to the line of the engine,,and connected to the crankshaft through a duplex chain-andsprocket drive These transmission units are impressively robust. being of a size normally found in a 5-ton lorry. The gear lever, of ball pattern, is mounted on the gearbox cover. All forward and reverse gears have a straight spur-tooth form.

The front-wheel-drive housing contains a toothed hub which engages with the gear machined on the gearbox mainshaft. This hub is bolted concentrically to the front-wheel centre .plate, which is supported on an axle, and a single blade

Because the engine, clutch and gearbox are carried on a platform incorporated with the blade and front wheel, they turn when the steering gear, which . „ is or 5-ton heavy-duty pattern attached to the frame at the head of the blade, is operated. As the clutch is actuated from the main frame, there is a flexible connection, in the form of a Bowden cable, between the pedal and operating unit.

• The driving "compartment" is a well, half of which is over the front-wheel end of the main frame. When fully depressed, the clutch pedal also operates the brakes on both rear wheels. A lever is connected to the brakes on one of the

rear wheels. This arrangement complies with the -law regarding braking systems on three-wheeled vehicles.

external lever, interconnected with the clutch-brake pedal, is provided so that the driver can walk alongside and control the vehicle for short distances without climbing into the driving well.

Before starting the trials, I filled fhe three-gallon fuel tank to the brim and borrowed a tool kit—just in case of mishap. From the outside, the tool box appears to be enormous, but part of its interior is taken up by a 100-1b. block of concrete, which is the counterbalance weight for the offset engine and transmission unit.

Before taking the Motocart on the main road, I spent 10 minutes in the works area at Elstree driving and familiarizing myself with the controls. With no load on board, there is little need for gear changing, and third gear can be used when moving away from rest. I found it rather a long reach to the gear lever, when steering on the lefthand lock, but, with experience, the driver would learn to engage an appropriate gear before turning a corner.

When preparing to leave the works-I engaged the cranking, handle in the

crankshaft dog to start the engine. A slow half-pull up, in an anti-clockwise direction, was sufficient to start the engine, which is a smoothrunning unit. A slight movement of the throttle control, attached to the steering head, increased the engine speed to governed revolutions, and after engaging gear the Motocart was driven away without fuss.

Without load, the three-wheeler kept a steady 10-12 M.p.h. all the way to a farm about five mites from EIstree, taking all hills in its stride, and without need for changing gear ' except when starting away from halt signs.

I took off my coat to load 25 1-cwt. bales of straw at the farm. The large platform body has space for 10 machine-packed bales, and with a second stack loaded, the straw was on a level with the top of the rave. Another five bales were added for good measure before leaving the rick.

Overcoming Wheeispin

An obstruction in the form of a step from soft earth to a cobbled surface at first caused wheel-slip, but the second attempt, with a 2-Yd. start, was more successful. If wheelspin develops when the Motocart is being driven forward, the driver always has the option of turning the vehicle and reversing over the' obstruction. This method can often be employed when negotiating slippery-surfaced gradients.

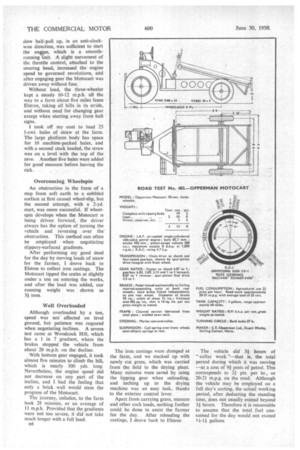

After performing my good deed for the day by moving loads of straw for the farmer, I drove back to Elstree to collect iron castings. The Motocart tipped the scales at slightly under a ton on entering the works, and after the load was added, our running weight was shown as 31 tons.

Well Overloaded Although overloaded by a ton, speed was not affected on level ground, but patience was required when negotiating inclines. A severe test came at Woodcock Hill, which has a 1 in 7 gradient, where the brakes stopped the vehicle from about 20 m.p.h. on the decline.

With bottom gear engaged, it took almost five minutes to climb the hill, which is nearly 300 yds. long Nevertheless, the engine speed did not decrease on any part of the incline, and I had the feeling that only a brick wall would stem the progress of the Motocart.

The journey, unladen, to the farm took 28 minutes, or an average of 11 m.p.h. Provided that the gradients were not too severe, it did not take much longer with a full load.

D6 The iron castings were dumped at the farm, and we stacked up with newly cut grass, which was carried from the field to the drying plant. Many minutes were saved by using the tipping gear when unloading, and inching up to the drying machine was an easy task, thanks to the exterior control lever.

Apart from carrying grass, manure and other such loads, nothing further could be done to assist the farmer for the day. After reloading the castings, I drove hack to Elstree

The vehicle did 31 hours of " collar work "—that is, the total period during which it was moving —at a cost of n pints of petrol. This corresponds to 24 pts. per hr., or 20-21 m.p.g. on the road. Although the vehicle may be employed on a full day's carting, the actual working period, after deducting the standing time, does not usually extend beyond 3i hours. Therefore it is reasonable to assume that the total fuel consumed for the day would not exceed

I gallons.