Farm Tractor or Lorry —

Page 106

Page 107

If you've noticed an error in this article please click here to report it so we can fix it.

a useful convertible outfit

A New Type of Vehicle which, in Fewer than Eight Minutes, Can be Converted from a Goods Vehicle to a Tractor

ANUMBER of valuable advantages is claimed for a new convertible farm vehicle, introduced by a German concern, which is intended to overcome the problems of the farmer in obtaining the maximum amount of use from his power equipment.

The unit, developed by the Atrag Co., 136-141, Frankfurter Allee in BerlinLichtenberg, consists of a frame with two endless-chain tracks, on which can be fitted two pneumatic-tyred wheels, enabling it to be drawn along, at normal road speeds, as a trailer. Any type of light lorry or motorcar can be converted into a chain tractor by means of this outfit, that illustrated being a Ford A 1-tonner.

A plough or other implement can be carried on the unit when this is employed as a trailer. A special detachable winch can be supplied to facilitate

the loading and unloading of the trailertrack unit.

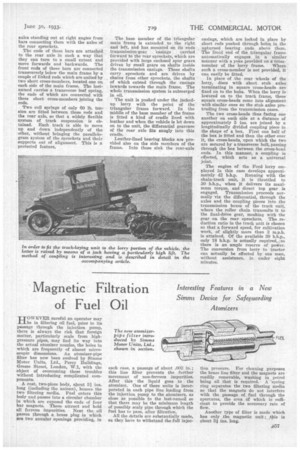

On arrival at the field, the lorry is jacked up by means of a high-lift jack mounted under the vehicle, and its rear wheels are removed. The road wheels ou the chain-track unit, which are carried only on short axles hooked into the track frame, are likewise removed, whereupon the track is pushqd under the lorry.

The last-named is now lowered, so

that its rear axle rests in bearings on the track frame, where they are secured by pins. Next, the hubs are connected, by means of a simple coupling device to be described later, with stub axles protruding from the transmission eases of the track unit. The conversion is then complete. The entire load is carried by the frame of the attached unit and the rear axle of the lorry is relieved of all stresses.

The two endless chains consist of a number of steel members articulated in a special manner, so that each is able to accommodate itself individually to the ground. Thus, each member is able to tilt sideways, and, for this reason, the track can operate even in the furrow, without undue stresses arising.

Moreover, the tracks are of the selflocking type ; that is the section on the ground between the sprockets cannot be forced upwards under the weight of the vehicle. In addition, a channel is fitted between the two sprockets, against which the chain presses, so that its joints are thus relieved of much of the stress.

The two rear sprockets are mounted on a common axle fixed on the equilateral side members of a triangular frame . of pressed-steel channels. The front sprockets are mounted on • stbb axles standing out at right angles from bars connecting them with the axles of the rear sprockets.

The ends of these bars are attached to the rear axle in such a way that they can turn to a small extent and move forwards and backwards. The front ends of these bars are connected transversely below the main frame by a couple of linked rods which are united by two short cross-members, located one on each side of the main frame. The lastnamed carries a transverse leaf spring, the ends of which are connected with these short cross-members joining the rods.

Two coil springs of only 60 lb. tension are fitted between these rods and the rear axle, so that a widely flexible system of track suspension is obtained. Each track is able to move up and down independently of the other, without bringing the pasallelogram system of the sprockets and their supports out of alignment. This is a protected feature.

The base member of the triangular main fratac is extended to the right and left, and has mounted on its ends transmission-gear -casings carried forward to the rear sprockets, which are provided with large enclosed spur gears driven by small gears on shafts inside the transmission casings. These shafts carry sprockets and are driven by chains from other sprockets, the shafts of which extend through the casings inwards towards the main frame. The whole transmission system is submerged in oil.

The unit is pushed under the jackedup lorry with the point of the triangular frame forward. In the middle of the base member of the frame is fitted a kind of cradle lined with leather and when the vehicle is let down on to the unit, the differential gearcase of the rear axle fits snugly into this cradle.

Leather-lined bearing blocks are provided also on the side members of the frame. Into these sink the rear-axle casings, which are locked in place by short rods pushed through holea in the upturned bearing ends above them. The front end of the triangular frame automatically engages in a similar manner with a yoke provided on acrossmember of the lorry frame. Where such a cross-member is not provided, it can easily be fitted.

In place of the rear wheels of the lorry, discs with short stub axles terminating in square cross-heads are fixed on to the hubs. When the lorry is lowered on to the track frame, these square cross-heads come into alignment with similar ones on the stub axles protruding from the transmission eases.

The two cross-heads thus facing one another on each side at a distance of approximately 5 ins, are joined by a longitudinally divided coupling piece in the shape of a box. First one half of the box is fitted and then the other over it, the cross-heads, upon which the two are secured by a transverse bolt, passing through the box between the cross-head ends. In this manner, a coupling is effected, which acts as a universal joint.

The engine of the Ford lorry employed in this case develops approximately 42 b.h.p. Running with the chain-track unit, it is throttled to SO b.h.p., when it delivers its maximum torque, and direct top gear is engaged. Transmission proceeds normally via the differential, through the axles and the coupling pieces into the transmission boxes of the track unit, where the roller chain transmits it to the final-drive gear, meshing with the gear on the rear sprockets. The reduction ratio in the track unit is chosen so that a forward speed, for cultivation work, of slightly more than 3 m.p.h. is attained. Of the available 30 b.h.p., only 18 b.h.p. is actually required, so there is an ample reserve of power. The conversion from lorry to tractor can actually be effected by one man, without assistance, in under eight minutes.