Eaton all-wheel-drive

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

EATON'S axle division in the USA has introduced a lightweight all-wheel-drive system for medium and heavy lorries.

It is known as the AWD, and eliminates the traditional transfer gearbox by using a special power divider and front-steerdrive axle.

The 6x6 version of the AWD is claimed to distribute power more efficiently than a transfer box system by distributing 75 per cent of the available torque to the bogie.

The AWD will be available in the UK where it is seen as a retrofit rather than an on-line option.

It is adaptable to a number of standard Eaton axles as it is built around the two-gear power divider used in all Eaton tandems.

The power divider itself has been modified to accept a helical gear for all-wheel drive.

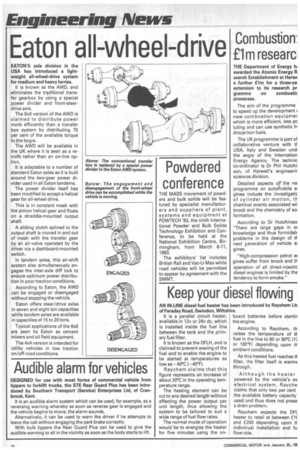

This is in constant mesh with the pinion helical gear and floats on a straddle-mounted output shaft.

A sliding clutch splined to the output shaft is moved in and out of mesh with the transfer gear by an air-valve operated by the driver via a dashboard-mounted switch.

In tandem axles, this air-shift system also simultaneously engages the inter-axle diff lock to ensure optimum power distribution in poor traction conditions.

According to Eaton, the AWD can be engaged or disengaged without stopping the vehicle.

Eaton offers steer/drive axles in seven and eight ton capacities while tandem axles are available in capacities of 15 to 20 tons.

Typical applications of the 6x6 are seen by Eaton as cement mixers and oil field equipment.

The 4x4 version is intended for utility vehicles in low traction on/off-road conditions.