Makes Good Progress with Prefabrication

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

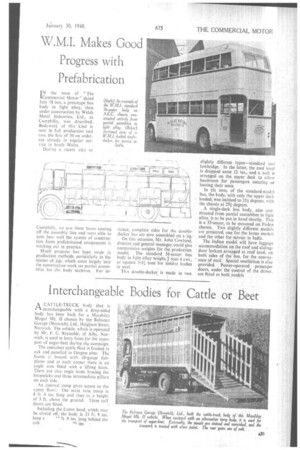

I N the issue of "The Commercial Motor " dated July 18 last, a prototype bus body in light alloy, then under construction by Welsh Metal Industries, Ltd„ at Caerphilly, was described. Bodywork of ibis kind is now in full production and two, the first of 50 on order, are already in regular service in South Wales.

During a recent visit to Caerphilly, we saw these buses coming off the assembly line and were able to note how well the system of construction from prefabricated components is working out in practice.

Much progress has been . made, in production methods, particularly in the matter of jigs, which enter largely into the construction work on partial assemblies for the body skeleton. For in

stance, complete sides for the doubledecker bus are now assembled on a jig. On this: occasion, Mr. John Cowland, director and general manager, could give conMarative Weights for the production model. . The standard 56-seater bus body in light alloy weighs tons 6 cwt., as against 3-31 tons for ‘sithilar bodies in steel.

This double-decker is made in two . , slightly different types—standard and lowbridge. In the latter, the roof level is dropped some 12 ins., and a well is arranged on the upper deck to allow headroom for passengers entering or leaving their seats.

In tilt tests, of the standard-model bus, the body, with only the upper deck loaded, was inclined to.35I degrees, with the chassis at 29i degrees.

A single-deck bus body, also constructed from partial assemblies in light alloy, is to be put in hand shortly. This is a 35-Seater, to be mounted on Foden chassis. Two slightly different models are projected, one for the home market and the other for service in India.

The Indian model will have luggage accommodation on the roof and slidingdoor lockers arranged at roof level, on both sides of the bus, for the conveyance of mail. Special ventilation is also provided. Power-operated passenger doors, under the control of the driver. are fitted to both models