New 1G-tonner and 32-ton unit from ERF

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

AIR SUSPENSION ON TWO SHOW MODELS

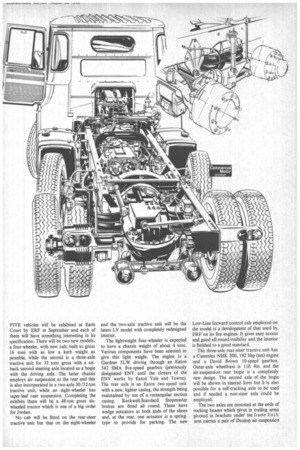

by A. J. P. Wilding, MIMechE, MIRTE FIVE vehicles will be exhibited at Earls Court by ERF in September and each of them will have something interesting in its specification. There will be two new models, a four-wheeler, with new cab, built to gross 16 tons with as low a kerb weight as possible, while the second is a three-axle tractive unit for 32 tons gross with a setback second steering axle located as a bogie with the driving axle. The latter chassis employs air suspension at the rear and this is also incorporated in a two-axle 30/32-ton tractive unit, while an eight-wheeler has taper-leaf rear suspension. Completing the exhibits there will be a 48-ton gross sixwheeled tractor which is one of a big order for Jordan.

No cab will be fitted on the rear-steer tractive unit but that on the eight-wheeler and the two-axle tractive unit will be the latest LV model with completely redesigned interior.

The lightweight four-wheeler is expected to have a chassis weight of about 4 tons. Various components have been selected to give this light weight. The engine is a Gardner 5LW driving through an Eaton 542 SMA five-speed gearbox (previously designated ENV until the closure of the ENV works by Eaton Yale and Towne). The rear axle is an Eaton two-speed unit with a new, lighter casing, the strength being maintained by use of a rectangular section casing. Rockwell-Standard Stopmaster brakes are fitted all round. These have wedge actuators at both ends of the shoes and, at the rear, one actuator is a springtype to provide for parking. The new

Low-Line forward control cab employed on the model is a development of that used by ERF on its fire engines. It gives easy access and good all-round visibility and the interior is finished to a good standard.

The three-axle rear-steer tractive unit has a Cummins NHK 200, 192 bhp (net) engine and a David Brown 10-speed gearbox. Outer-axle wheelbase is lift 4in. and the air-suspension rear bogie is a completely new design. The second axle of the bogie will be shown in steered form but it is also possible for a self-tracking axle to be used and if needed a non-steer axle could be employed.

The two axles are mounted at the ends of rocking beams which pivot in trailing arms pivoted in brackets under the Frame. Each arm carries a pair of Dunlop air-suspension

units. The tops of the air springs are mounted directly under the frame side-members and the pivot points on the rocking beams are located so that the 16-ton designed bogie load is distributed in the proportion of 10 tons on the driving axle and 6 tons on the forward axle.

Spring-brake actuators are fitted at the front and driving axles and the brake effort at the rear brakes is adjusted according to load through a valve connected to the airsuspension system. Telescopic dampers connect the trailing arms to the chassis frame and there is substantial anti-roll bar linking the trailing arms.

The cab used on the 6 X 4 tractive unit for the Jordan order is made by Motor Panels. It is an all-steel sleeper cab and will in future be standard for ERF export vehicles. The model is designed for use overseas at a gross combination weight of 47.8 tons. The engine is a Rolls-Royce Eagle 220 bhp diesel and the transmission is through a Fuller RT0915 15-speed twin-layshaft gearbox. The two-spring, double-drive rear bogie has a lockable third differential; final drive ratio is 6.91 to 1, giving a maximum speed of 46 mph.

Air suspension The air suspension as used on the twoaxle tractive unit to be shown by ERF is reported to have given excellent results during lengthy tests. There are Dunlop air springs at the front and rear of fabricated beams which carry the axle at their centres. Above the axle is a two-leaf semi-elliptic spring at each side, locating the axle to the chassis, and both the suspension beams are linked to the frame side-members by a pair of telescopic dampers, one in front and one behind the axle; there is also an anti-roll bar. The show exhibit will be powered by a Gardner 6LXB engine driving through a David Brown six-speed gearbox; the rear axle an Eaton 19800 two-speed unit.

The eight-wheeler to be shown by ERF will be the concern's standard design for 24 tons gross with a Gardner 6LX engine, David Brown gearbox and Kirkstall double

drive rear axles. The taper-leaf springs fitted at the rear will become standard on sixand eight-wheelers made by ERF where a four-spring balance beam layout is used. The springs, which each have three leaves, are made by Bramber Engineering under licence to Rockwell-Standard of America. In the ERF application the springs are located on top of the axle casing as against the firm's normal practice of an underslung rear-spring layout; this reduces roll and shackle-pin wear which adds to the advantages of weight saving for the springs.

A number of modifications have been made to the interior of the ERF LV cab in producing the latest design to be shown on the two chassis at Earls 'Court. The seat, gear lever and steering wheel positions have been altered to make for improved driver control, the clutch and brake pedal designs have been changed and an organ-type accelerator pedal is used with a new linkage. A new facia panel is used and electrical equipment is mounted on separate panels which are easily detachable for servicing.