Lightweight 16-ton Guy has Leyland 401 diesel

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

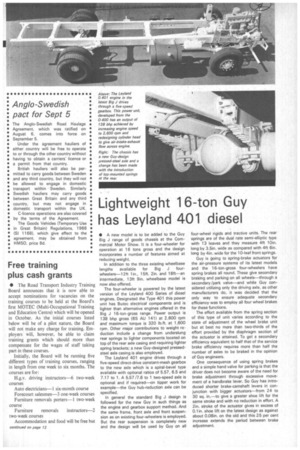

• A new model is to be added to the Guy Big J range of goods chassis at the Commercial Motor Show. It is a four-wheeler for operation at 16 tons gross and the design incorporates a number of features aimed at reducing weight.

In addition to the three existing wheelbase lengths available for Big J fourwheelers-12ft 1in., 15h. 2in. and 18ft—an intermediate, 13ft 9in. wheelbase model is now also offered.

The four-wheeler is powered by the latest version of the Leyland 400 Series of diesel engines. Designated the Type 401 this power unit has Butec electrical components and is lighter than alternative engines offered in the Big J 16-ton-gross range. Power output is 138 bhp gross (BS AU 141) at 2,600 rpm and maximum torque is 320 lb.ft. at 1,600 rpm. Other major contributions to weight reduction include a change from underslung rear springs to lighter components located on top of the rear axle casing and requiring lighter spring brackets; a new Guy-designed pressedsteel axle casing is also employed. The Leyland 401 engine drives through a five-speed direct-drive constant-mesh gearbox to the new axle which is a spiral-bevel type available with optional ratios of 5.57, 6.5 and 7.17 to 1. A 5.57/7.6 to 1 two-speed axle is optional and if required—on tipper work for example—the Guy hub-reduction axle can be specified.

In general the standard Big J design is followed for the new Guy in such things as the engine and gearbox support method. And the same frame, front axle and front suspension as on existing four-wheelers is employed. But the rear suspension is completely new and the design will be used by Guy on all four-wheel rigids and tractive units. The rear springs are of the dual rate semi-elliptic type with 13 leaves and they measure 4ft 10in. long by 3.5in. wide as compared with 4ft 6in. long by 4in. wide for the 10-leaf front springs.

Guy is going to spring-brake actuators for the air-pressure systems of its latest models and the 16-ton-gross four-wheelers have spring brakes all round. These give secondary braking and parking on all wheels—through a secondary /park valve—and while Guy considered utilizing only the driving axle, as other manufacturers do, it was decided that the only way to ensure adequate secondary efficiency was to employ all four wheel brakes for these functions.

The effort available from the spring section of this type of unit varies according to the state of adjustment of the wheel brake unit but at best no more than two-thirds of the effort provided by the diaphragm section of the actuator is attained. To get a secondary efficiency equivalent to half that of the service brake efficiency requires more than half the number of axles to be braked in the opinion of Guy engineers.

One consequence of using spring brakes and a simple hand valve for parking is that the driver does not become aware of the need for brake adjustment through excessive movement of a handbrake lever. So Guy has introduced shorter brake-camshaft levers in conjunction with bigger actuators—from 24 to 30 sq. in. --to give a greater shoe lift for the same stroke and with no reduction in effort. A 2in. stroke of the actuator gives in excess of 0.1 in. shoe lift on the latest design as against about 0.08in. on the old and this 25 per cent increase extends the period between brake adjustment.