How it works: BOGIE LIFT

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

by The Technical Editor

WHEN driving tippers and other trucks in off-road conditions one of the main problems is how to get enough traction and here the use of a bogie lift is claimed to give a 6x2 truck significant advantages over a 6x4 model. In theory the bogie lift principle of operation is simplicity itself.

If the trailing rear axle is raised clear of the ground then an extra load is applied through the drive axle which has two effects. The first is an obvious one in that the traction will benefit by the increase in drive axle loading and the second is that a decrease in the front axle loading is achieved by virtue of the moment of the lifted trailing axle about the axis of the drive axle.

For on-site work this decrease in front axle loading is important as it lessens the tendency of the front wheels to "plough on" when turning on loose surfaces. That is the idea in theory; now let's have a look at the actual mechanics of the system as used on a Scania 85.

The actual method of raising the axle is very simple. Mainly seen in this country on Scanias and Volvos, the mechanism can vary in some of the minor points of detail, but the basic principle is the same.

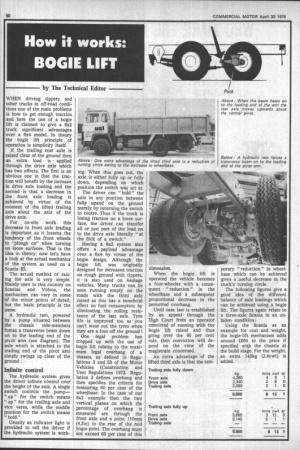

A hydraulic ram, powered by a pump situated between the chassis side-members forces a transverse beam down on to the leading end of the pivot arm (see diagram). The axle which is attached to the trailing end of the pivot arm simply swings up clear of the ground .

Infinite control

The hydraulic system gives the driver infinite control over the height of the axle. A single switch controls the pump" up " for the switch means " up" for the trailing axle and vice versa, while the middle position for the switch means "hold."

Usually an indicator light is provided to tell the driver if the hydraulic system is work ing. When this goes out, the axle is either fully up or fully down, depending on which position the switch was set at.

The driver can " hold " the axle in any position between fully upand on the ground merely by returning the switch to centre. Thus if the truck is losing traction on a loose surface, the driver can transfer all or just part of the load on to the drive axle literally "at the flick of a switch."

Having a 6x2 system also offers a payload advantage over a 6x4 by virtue of the bogie design. Although the bogie lift was originally designed for increased traction on rough ground with tippers, it is also used on haulage vehicles. Many trucks can be seen running empty on the roads with the third axle raised as this has a beneficial effect on fuel consumption by eliminating the rolling resistance of the last axle. Tyre life is improved too as you can't wear out the tyres when they are a foot off the ground !

One legal problem has cropped up with the use of bogie lift relates to the maximum legal overhang of a chassis, as defined in Regulations 3 and 53 of the Motor Vehicles (Construction and Use) Regulations 1973. Regulation 3 defines overhang and then specifies the criteria for measuring 60 per cent of the wheelbase. In the case of our 6x2 example then the two vertical planes on which the percentage of overhang is measured are through the front axle and a point 110mm (4.3in) to the rear of the mid bogie point. The overhang must not exceed 60 per cent of this dimension.

When the bogie lift is operated the vehicle becomes a four-wheeler with a consequent " reduction " in the wheelbase and a subsequent proportional decrease in the permitted overhang.

Until case law is established by an appeal through the High Court from an operator convicted of running with the bogie lift raised and thus going over the 60 per cent rule, then conviction will depend on the view of the magistrate concerned.

An extra advantage of the lifted third axle is that the tern porary " reduction " in wheelbase which can be achieved gives a useful decrease in the truck's turning circle.

The following figures give a good idea of the different balance of axle loadings which can be achieved using a bogie lift. The figures again relate to a three-axle Scania in an unladen condition : Using the Scania as an example for cost and weight, the bogie-lift mechanism adds around £,650 to the price if specified with the chassis at the build stage. For the weight, an extra 143kg (2.8cwt) is added.