Demounting by numbers

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

AN AGREEMENT between a British and a Continental demountable body manufacturer has meant the introduction of a new form of demountable body in Britain this week.

Freight Bonallack has a two-way agreement with Renova of Holland that allows the British manufacturer to produce a new guiderail mechanical demounting system.

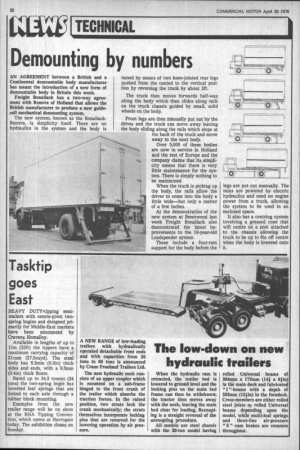

The new system, known as the BonallackRenova, is simplicity itself. There are no hydraulics in the system and the body is raised by means of two knee-jointed rear legs pushed from the canted to the vertical position by reversing the truck by about 2ft.

The truck then moves forwards half-way along the body which then slides along rails on the truck chassis guided by small, solid wheels on the body.

Front legs are then manually put out by the driver and the truck can move away leaving the body sliding along the rails which slope at the back of the truck and move away to the next body.

Over 5,000 of these bodies are now in service in Holland and the rest of Europe and the company claims that its simplicity means that there is very little maintenance for the system. There is simply nothing to be maintained.

When the truck is picking up the body, the rails allow the driver to come into the body a little wide—but only a matter of a few inches.

At the demonstration of the new system at Brentwood last week Freight Bonallack also demonstrated the latest improvements to the 10-year-old Loadspeeder system.

These include a four-ram support for the body before the legs are put out manually. The rams are powered by electric hydraulics and need no engine power from a truck, allowing the system to be used in an enclosed space.

It also has a centring system involving a greased cone that will centre on a post attached to the chassis allowing the truck to be up to 6in off centre when the body is lowered onto it.