The Hydrafreighter Lifts Itself by its 0 draulic Bootstraps

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

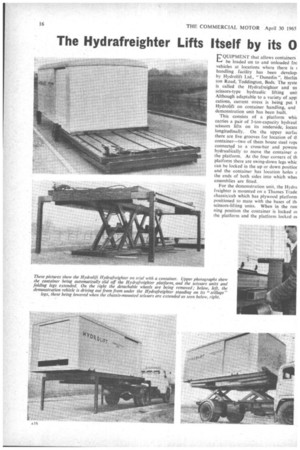

EQUIPMENT that allows containers 1--# be loaded on to and unloaded firc vehicles at locations where there is handling facility has been .develop, by HydroIift Ltd,, " Dunedin", Harlin ton Road, Toddington, Beds. The syste is called the Hydrafreighter and us scissors-type hydraulic lifting unii Although adaptable to a variety of app] cations, current stress is being put 1 Hydrolift on container handling, and demonstration unit has been built.

This consists of a platform whit carries a pair of 3-ton-capacity hydraul scissors lifts on its underside, locate longitudinally. On the upper surfac there are five grooves for location of tt container—two of them house steel ropt connected to a cross-bar and powere hydraulicallyto move the container o

the platform. At the four corners of fill platform there are swing-down legs whic

can be locked in the up or down positiot and the container has location holes E the ends of both sides into which whet assemblies are fitted.

For the demonstration unit, the Hydra freighter is mounted on a Thames Trade chassis/cab which has plywood platform positioned to mate with the bases of th scissors-lifting units. When in the run ning position the container is locked oi the platform and the platform locked oi I the chassis frame at four points with lick-release couplings.

To remove the container, the platform leks are released and the hydraulic lifts tised—a gearbox p.t.-o. pump provides le power—to a height which allows the ipport legs to be lowered. When these re locked down the load is let on to tem and the vehicle driven from under Se platform. The scissors lifts are then owered again to bring their basesto se ground and take the load off the legs, he latter are then folded up and the Ju r wheels fitted to the container.

• Next: the container and platform are iwered—the rams in the lifting, units are owercd both up and down—until the wheels are on the ground. The container can then be pushed off this platform by the means referred to earlier. To load a container the reverse procedure is used.

When the Hydrafreighter system was demonstrated to The Commercial. Motor a number of snags `crcipped up, but the equipment was a prototype and minor difficulties could be expected. This meant that the operation could not be timed, but it was obvious that the system has considerable potential. The snags occurred when putting the container back on to the vehicle; lowering it went smoothly, the time taken being about four minutes. About the same time should be taken to get the container back on to the vehicle chassis.

Although the demonstration model is made up of scissors lifts with a capacity of three tons, when mounted to a vehicle providing hydraulic " pressure of 2,000 psi., these become capable of lifting four tons. In this form the weight of each scissor unit is 375 cwt, and the weight of the push-off unit, complete with its wheels, 4-25 cwt. To these ,must be added the weight of whatever type platform is employed.

Each four-ton unit costs £160 and the number of units needed should be calculated to the next higher multiple of four tons (e.g. two units to lift from over 4 up to 8 tons, three from over 8 tons to 12). The push-off unit costs in the region of £900 depending entirely on the requirements of the customer.