IN THE

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

ROI.%

By

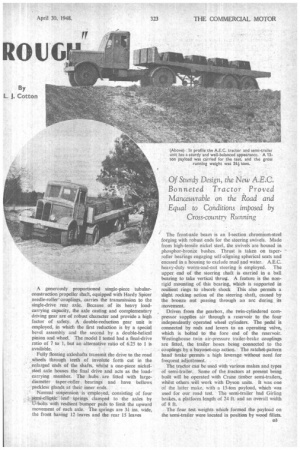

1. J. Cotton II should be made clear at the outset that the heading to this article has been borrowed from golfers' jargon and that the word " tough " does not apply to the construction of the new A.E.C. left-hand-drive tractor. In fact, it.is designed to withstand the heavy service demanded of most overseas vehicles. It was the robust character of the machine that suggested a trial, which constituted part of our test, over the rough territory of the Ministry of Supply Tank-proving ground.

With only one driving axle for the tractor and semitrailer unit and running with a gross weight of 24i tons, I had doubts as to the traciion on the soft surface, which had already been well churned up by Tank tracks. However, the tractor scored full points until an attempt was made to ascend a soft-earth gradient of J in 3.88, when wbeelspin developed and prevented further trials on similar-surfaced steeper gradients. .

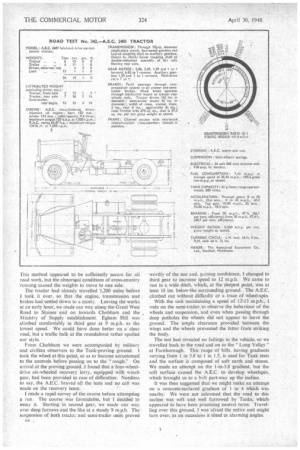

The A.E.C. standard 9.6-litre direct-injection oil engine, which develops 125 b.h.p. at 1,800 r.p.m., is used for the tractor power unit. This engine, which is an example of modern design, has overhead valve gear, two valves per cylinder and helical gear-driven auxiliaries. Thick steel-shell main and big-end bearings are used with a lining of white metal on the main bearing upper halves and lead-bronze for the remainder of the shells. In common with all A.E.C. oil engines, the cylinder block is a one-piece casting, bolted tothe upper face of the crankcase by the main-bearing bolts,

which are extended upwards for this purpose.

A single-plate clutch with a friction area of 320 sq. ins, carries the drive to the four-speed gearbox, which is of constant-meslMesign. Fourth and third, speeds are engaged by means of dog clutches. Of unit construction with the engine and clutch, the main gearbox is supported by a steel banjo pressing at the rear of the engine. A short, robust Layrub coupling shaft forms the connection between the main and auxiliary gearboxes. The auxiliary gearbox provides a reduction of 1.58 to 1 as an alternative to the dog-engaged direct . drive.

It is operated by a separate lever and so arranged that direct drive in the auxiliary box can be engaged only after top gear in the main gearbox has been selected. The main and auxiliary gearboxes will be fitted to the first 100 chusis; vehicles produced subsequently will have five-speed gearboxes, which will also be adopted on all other A.E.C. models which at present are fitted with auxiliary gearboxes,

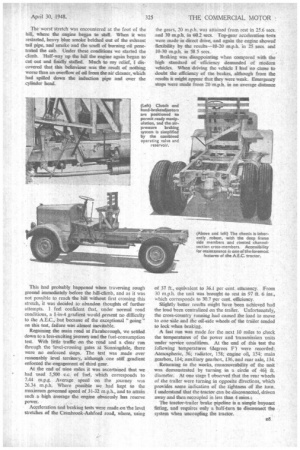

A generously proportioned single-piece tubularconstruction .propeller shaft, equipped with Hardy Spicer needle-roller' couplings, carries the transmission to the single-drive rear axle. Because of its heavy loadcarrying capacity, the axle casting and complementary driving gear are of robust character and provide a high factor of safety. A double-reduction gear unit is employed, in which the first reduction is by a special bevel assembly and the second by a double-helical pinion and wheel. The model I tested had a final-drive ratio of 7 to 1, but an alternative ratio of 6.25 to 1 is available.

Fully floating axleshafts transmit the drive to the road wheels through teeth of involute form cut in the enlarged ends of the shafts, whilst a one-piece nickel steel axle houses the final drive and acts as the loadcarrying member. The hubs are fitted with largediameter taper-roller bearings and have bellows packlesk glands at their inner ends.

Normal suspension is employed, consisting of four leaf spiings clamped to the axles by -10-bolts with resilient bumper pads to limit the upward movement of each axle. The -springs are 31 ins, wide, the front having 12 leaves and the rear• 15 leaves The front-axle beam is an 1-section chromium-steel forging with robust ends for the steering swivels. Made from high-tensile nickel steel, the swivels are housed in phosphor-bronze bushes. Thrust is taken on taperroller bearings engaging self-aligning spherical seats and encased in a housing to exclude mud and water. A.E.C. heavy-duty worm-and-nut steering is employed. The upper end of the steering shaft is carried in a ball bearing to take vertical thrust. A feature is the nonrigid mounting of this bearing, which is supported in resilient rings to absorb shock This also permits a slight rocking action of the steering shaft, caused by the bronze nut passing through an arc during its movement.

Driven from the gearbox, the twin-cylindered compressor supplies air through a reservoir to the four independently operated wheel cylinders. The pedal is connected by rods and levers to an operating valve, which is bolted to the fore end of the reservoir. Westinghouse twin air-pressure trailer-brake couplings are fitted, the trailer hoses being connected to the couplings by a bayonet-cap action. The ratchet-pattern hand brake permits a high leverage without need for frequent adjustment.

The tractor can be used with various makes and types of semi-trailer. Some of the tractors at present being built will be operated with Crane timber semi-trailers, whilst others will work with Dyson units. It was one of the latter make, with a 15-ton payload, which was used for our road test. The semi-trailer had Girling brakes, a platform length of 24 ft. and an overall width of 8 ft,.

The four test weights which formed the payload on the semi-trailer were located in position by wood fillets. This method appeared to be sufficiently secure for all road work, but the abnormal conditions of cross-country running caused the weights to move to one side.

The tractor had already travelled 1,200 miles before 1 took it over, so that the engine, transmission and brakes.had settled down to a nicety. Leaving the works at an early hour, we made our way along the Great West Road to Staines and on towards Chobharn and the Ministry of Supply establishment. Egham Hill was climbed comfortably in third gear at 9 m.p.h. as the lowest speed. We could have done better on a clear road, but a traffic balk at the roundabout rather spoiled our style.

From .Chobham we were accompanied by military and civilian observers to the Tank-proving ground. took the wheel at this point, so as to become accustomed to the controls before passing on to the "rough." On arrival at the proving ground, 1 found that a four-wheeldrive six-wheeled recovery lorry, equipped with winch gear, had been provided in case of difficulties. Needless to say, the A.E.C.braved all the tests and no call was made on the recovery team.

made a rapid survey of the course before attempting a run. The course was formidable, but I decided to essay it. Starting in second gear, we made our way over deep furrows and the-like at a steady 9 m.p.h. The suspension of both tracto: and semi-trailer units proved L)4 ,

worthy of the test and, gaining confidence, t changed to third gear to increase speed to 12 m.p.h. We came to rest in a wide ditch, which, at the deepest point, was at Least 18 ins. below-the surrounding ground. The A.E.C. climbed out without difficulty or a trace of wheel-spin.

With the unit maintaining a speed of 12-13 m.p.h., rode on the semi-trailer to observe the behaviour of the wheels and suspension, and even when passing through deep potholes the wheels did not appear to leave the ground. The ample clearance provided between the wings and the wheels prevented the latter from striking' the body.

The test had revealed no failings in the vehicle, so we travelled back to the road and on to the "Long Valley" at Farnborough. This range of hills, having gradientsvarying from 1 in 3.8 to 1 in 1.5, is used for Tank tests and the surface is composed of soft earth and stones. We made an attempt on the I-in-3.8 gradient, but the soft surface caused the A.E.C. to develop wheelspin, which brought us to a halt part-way up the incline.

It was then suggested that we might make an attempt on a concrete-surfaced gradient of 1 in 4 which was nearby. We were not informed that the road to this incline was soft and well furrowed by Tanks, 'which appeared to have been practising neutral turns. Travelling over this ground, I was afraid the entire unit might turn over, as on occasions it tilted at alarming angles.

Theworst stretch was encountered at the foot of the hill, where the .erigine began to still_ When it as restarted, heavy blue smoke belched out of the exhaust tail pipe, and smoke and the smell :of burning iI pene:trailed the cab. 'Under these .conditions 'we started the elirrib. Half-way w) ?the hill the engine again began to out out :and finaily stand. Miadh to my Fetid, if discovered that this behaviour was the result of :thing worse than an otierflow of OE fri2X811 the air cleaner, w'hieli had npril.kid down the induction pi;pe and otier the cylinder liewni.

This .had probably happened when traversing rough ground immediately before the hili-climb, and as it was not possible to reach the hill without first crossing this stretch, it was decided to abandon thoughts of further attempts. I feel confident that, under normal road conditions, a 1-in-4 _gradient would present no diffictilty to the A.E.C., but because of the exceptional "going" on this test, failure was almost inevitable.

Regaining the main road at Farnborough, we settled down to a less-exciting journey and the fuel-consumption test. With little traffic on the road and a elmir rem through the level-crossing gates at Sunningdale, there were no enforced stops. The test was made over reasonably level territory, :although one stiff gradient enforced the .engagernern of third gear.

At the end of nine miles it was ascertained that we had used 5,500 c.c. of fuel, which corresponds to 7.44 rnp.g. Average speed on the Journey was 26.34 m.p.h. Where pos4ib4e we had kept to the maximum governed speed of 31-32 m.p.h., and to attain such a high average the engine .obviously has reserve r-KYE. .

Acceleration and braking tests 'were made orethe level stretches of the Cranbrook-Ashiarcl road, where, using the gears, 20 m.p.h. was attained from rest in 256 secs.and 30 m.p.h. inteR2 'sem -Top-gear acceleration tests were .made in direct dra, an& again the engine showed by the results-10-241) sitt,ph. in secs. and I0-30 impla. in 55 sees.. Braking was disappointing When Aveattpared \nth the high gtandand of • efficiency (demanded of /*Odom Au:hides. When ,t1rMitig the tehiele .1 had no eartise to dotibt the efficiency icif the brakes, nithough fawn the 4CSIlati3 it Might appear That they were weak. Emergency .stops were made front 20 re,pk in ae. average distance et 57 ft., 'equivalent to 36.1 per cent. efficiency. From 30 m.p.h. the unit was brought to rest in 97 ft. ins., which corresponds to 30.7 per cent. efficiency.

Slightly better resets might have been achieved had the lead been centralized on The trailer. Unfortunately, The ercisscountry running had caused the iload to move to one -6-le and the oil-side wheels of the trailer tended to lock when braking.

A fast ran was made for the next 10 miles to check the temperatures of the power and transmission units under serVice conditions. At The end of this test the following temperatures Viegrees F) were recorded: Atmospheric, 56:, radiator, 15/3,-, engine oil, 154; main _gearbox., 1.14.; auxiliary gearbox, 3136, and rear aide, 134.

Returning to the works, manceuvrability of the unit was demonstrated by turning in a circle of .46i ft. diameter. At one stage I observed that the rear 'wheels of the trailer were turning in opposite directions, -which pros/ides some indication Of the tightness of the turn.

understand that the tractor can he disconnected, driven away and then recoupled in less than 4 oars., The tractor-trailer -brake pip-thine is a simple bayonet lilting, and requires only a haiff-turn to disconnect the system when uncoupling the tractor.