British Engine Design

Page 115

Page 116

Page 117

Page 118

If you've noticed an error in this article please click here to report it so we can fix it.

A Commentary on the Latest

• Technical Practice, and Notes

• on Tendencies Particularly in connection with Power Units for Overseas

By-G. Mackenzie Junner,

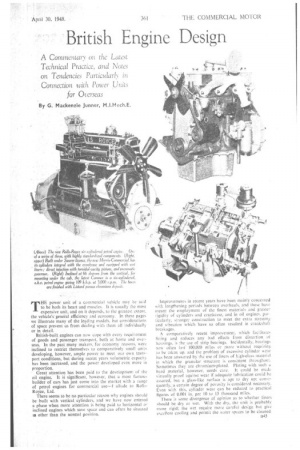

TkIE power unit of a commercial vehicle may be said to be both its heart and muscles. It is usually the most expensive unit, and on it depends, to the greatest extent, the vehicle's' general efficiency and economy, in these pages we illustrate many of the leading models, but considerations of space prevent us from dealing with them all individually

or in detail. , -

British-built engines can now cope with every requirement of goods and .passenger transport, both at home and overseas. In the past many makers, for economy reasons, were inclined to restrict themselves to comparatively small units developing, however, ample power to meet ourown transport conditions, but during recent years volumetric capacity has been increased, and the power developed even more in proportion.

Great attention has been paid to the development of the oil engine. It is significant, however, that a most famous builder of cars has just come into the market with a range of petrol engines for commercial use—l• allude to RollsRoyce, Ltd.

There seems to be no particular reason why engines should be-built with vertical, cylinders, and we have now entered a phase when -more attention is being paid to horizontal or inclined engines which save space and can often be situated in other than the normal position. Improvements in recent years have been mainly concerned with lengthening periods between overhauls, and these have meant the employment of the finest materials and greater rigidity of cylinders and crankcase, and in oil engines, particularly. stronger construction to meet the extra stressing and vibration which have so often resulted in crankshaft breakages.

A comparatively recent improvement, which facilitates fitting and reduces any bad effects from distortion ot housings, is the use of strip bearings. incidentally, hearings now often last* 100,000 miles or more without requiring to be taken up. and the problem of excessive cylinder wear has been answered by the use of liners of high-class material in which the granular structure is consistent throughout. Sometimes they are chromium-plated. Plating with such a hard material, however, needs care. It could be made virtually proof against wear if adequate lubrication could be assured, hut a glass-like surface is apt to dry up; consequently, a certain degree of porosity is considered necessary. Even with this, cylinder wear can be reduced to practical figures of 0.001 in. per 10 to 15 thousand miles.

There is sonic divergence of opinion as to whether liners should be dry or wet. With the dry, the unit is probably more rigid; the wet require more careful design but give excellent cooling and permit the water spaces to be cleaned. At one time liners were invariably pressed into position, then came the freezing process when they were dipped into liquid air or oxygen before insertion. Now sometimes they almost float and can be pushed in by hand, being held firmly by the cylinder head.

There are varying opinions as to the hardening of crankshafts, but the majority of engines, particularly oilers, have high-quality crankshafts either hardened and tempered throughout, or surface-hardened.

There appears to be a preference for chain operation for the timing gear, combined with some efficient device to take up stretch, but pinions are often employed. Here, again, there is a question as to whether it should be situated at the back or front. It is argued that when at the back, timing is not affected by torsional stressing of the crankshaft, but unless special precautions he taken, accessibility is apt to suffer.

Many improvements have been effected in pistons and rings, and it has long been realized that the average piston could not expand equally all around and along its length under the influence of heat. Many are, therefore, now ground both oval and taper. This treatment allows smaller clearances between pistons and cylinders. Ring sticking has also been reduced. in some cases, by tapering the sides of the compression type, whilst slots and grooves in scraper rings often prove better than drilling and grooving, particularly in the reduction of carbon deposit.

In oil engines, direct injection is largely replacing indirect, except for smatter units. In some cases, piston heads are recessed to form part of the combustion chamber, the shape,

often being toroidal. Masked inlet valves are used frequently to give additional swirl. Some consider that engines with indirect injection give a better performance, but their disadvantages have been higher fuel consumption and difficulty in starting Two-stroke-cycle engines have not made much headway in Britain, chiefly because higher fuel consumption is feared. It is, therefore, particularly interesting to note that the new Foclen oil unit is of this type, working on the Kadenacy principle. Full details of this are not yet available, but reports indicate that it is giving an excellent performance.

Again, in oil engines, injection pumps have now reached a high stage, of efficiency, whilst many improvements have been made in injectors, with a view to obviating coking. The sprays are the subject of constant investigation. In the most recently designed nozzles, the form and length of the spray vary according to the engine requirements. At present, pneumatic governors for injection pumps appear to be the most popular. Some designers and users believe, however, that the hydraulic type being more rapid in action possesses good possibilities.

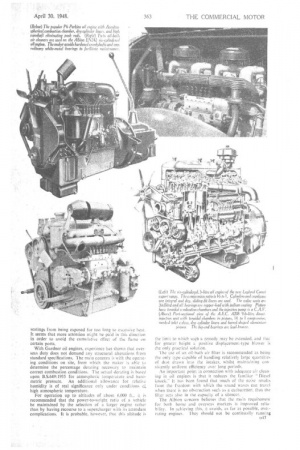

The Thornycroft ER4 four-cylindered petrol engine has a somewhat unusual exhaust manifold. It is designed in such a way that the flame travel is kept as far as possible away from each individual port, thus preventing the valve heads and

seatings from being exposed for too lone to excessive heat. It seems that more attention might be paid in this direction in order to avoid the cumulative effect of the name on certain ports.

With Gardner oil engines, experience has shown that overseas duty does not demand any structural alterations from standard specifications. The main concern is with the operating .conditions on site, from which the maker is able to determine the percentage derating necessary to maintain correct combustion conditions. The actual derating is based upon B.5.649:1935 for atmospheric temperature and baro

metric 'pressure. An additional allowance for relative huniidity is of real significance only under conditions at high atmospheric temperature.

For operation up to altitudes of about 600 ft.. it is recommended that the power-to-weight ratio of a vehicle be maintained by the selection of a larger engine rather than by having recourse to a supercharger with its attendant complications. It is probable, however, that this altitude is the limit to which such a remedy may be extended, and that for greater height a positive displacement-type blower is the only practical solution.

The use of an oil-bath air filter is recommended as being the only type capable of handling relatively large quantities of dust drawn into the intakes, whilst maintaining consistently uniform efficiency over long periods.

An important point in connection with adequate air cleaning in oil engines is that it reduces the familiar " Diesel knock." It has been found that flinch of the noise results front the freedom with which the sound waves can travel when there is no obstruction such as a carburetter; thus the filter acts also in the capacity of a silencer.

The Albion concern believes that the main requiremeni for both home and overseas markets is improved reliability. In achieving this, it avoids, as far as possible, over

engines. They should not he continually running

"up to. the collar" in respect of their power outputs. Also in mind, is the need for easy maintenance. Hence the company avoids such features as hardened crankshafts, which, to overseas users. in particular, present difficulties in re-heat treatment when it becomes necessary to regrind. It prefers, also, to use ordinary white-metal. bearings rather than the copper-lead type, as the latter require more skill and care during refitting and maintenance, and are more susceptible to faults or carelessness in engine lubrication.

Considerable importance is attached to the fitting on oil -engines of fuel filters. in series, as it has been found that, however much care be taken when cleaning the primary filter,. some dirt is dislodged, and this would reach the fuel pump and iniectors were it not trapped by a secondary filter.

In this case also large-capacity oil-bath air cleaners are coasidered essential.

Engine cooling for overseas work requires particular attention, and efficiency can be promoted by such devices as Still-tube radiator blocks, and large-diameter fans, well cowled.

Radiator elements differ widely in their heat-dissipating capacity, and allowances must accordingly be made.

The starting of engines, particularly in places. where there is likelyto be extreme cold, is a matter of considerable importance. As a general rule, heater plugs are objectionable. Batteries lose much of their efficiency, and recourse may be necessary to modern aids such as power cartridges, whilst for petrol engines special means, suchas supplies of ether, may be found advisable.

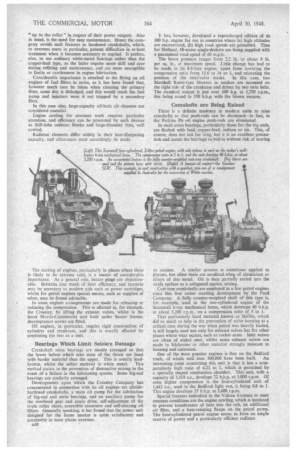

In some engines arrangements are made for releasing or reducing the compression. This is effected in, for example, the Crossley, by Lifting the exhaust valves, whilst in the latest Morris-Commercial unit built under Saurer licence, decompressor screws are fitted.

Oil engines, in particular, require rigid construction of cylinders and crankcase, and this is usually effected by combining the two as a emit.

Bearings Which Limit Seizure Damage Crankshaft main bearings are mostlyarranged so that the lower halves which take most of the thrust are lined with harder material than the upper. This is usually lead

bronze, whilst the softer material is white metal. This method assists in the prevention of destructive seizing In the event of a failure in the lubricating system. Some big-end hearings are similarly arranged.

Developments upon which the Crossley Company has concentrated in connection with its oil engines are nitridehardened crankshafts, a main oil pump for the lubrication of big-end and main bearings, and an auxiliary pump for the overhead gear and chain drive, self-adjustment of the triple roller chain, accessible atomizers and self-clearing oiL Filters. Generally speaking, it has found that the power unit designed for the home market is quite satisfactory and acceptable in most places overseas.

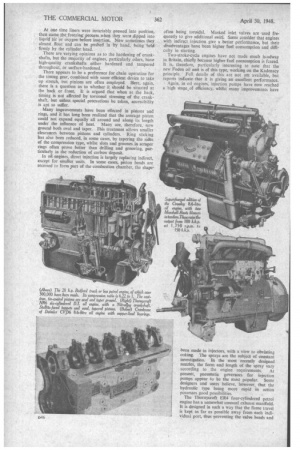

D48 It has, however, developed a supercharged edition of its 100 h.p.. engine for use in countries where (a) high altitudes are encountered, (b) high road speeds are permitted. Thus for Holland, 48-seater sing,le-deckers are being supplied with a guaranteed road speed of 60 m.p.h.

The boost pressure ranges from 2.2 lb. to about 8 lb. per sq. in., at maximum speed. Little change has had to he made in its 8.6-litre engine, apart from lowering the compression ratio from 15.6 to 14 to 1, and relocating the position of the inlet-valve masks. In this case, two Marshall Roots-type blowers in tandem are mounted on the right side of the crankcase and driven by two twin belts. The standard output is just over 100 h.p. at 1,750 r.p.m., this being raised to 150 black with the blown version_

Camshafts are Being Raised There is a definite tendency in modern units. to raise camshafts so that push-rods can be shortened—in fact, in the Perkins P6 oil engine ptish-rods are eliminated..

In most cases bearings, particularly those for the big ends, are flashed with lead,. copper-le-ad, indium or tin. This, of course, does not last for long, hut it is an excellent precaution and assists the bearings to bed-in without risk of scoring or seizure. A similar process is sometimes applied to

pistons, but often these are anodized. wheo of aluminium or alloys of this metal. Oil is then partially sealed into the oxide surface as a safeguard against seizing.

Cast-iron crankshafts are employed in a few petrol engines since this first rather startling development by the Ford Company, A fully counter-weighted shaft of this type is, for • example; used in the two-cylindered engine of the Scammell 6-ton mechanical horse, which develops 40 b.h.p. at about 3,200 roam., on a compression ratio of 5 to I.

That particularly hard material known as Stcllite, which did so much to help in the prevention of valve burning at a critical time during the war when petrol was heavily leaded, is still largely used not only for exhaust valves but for other places where wear occurs, such as rocker arms. Inlet valves are often of nickel steel, whilst some exhaust valves are made in Silchrome or other material strongly resistant to burning and corrosion. One of the most popular engines is that on the Bedford truck, of which well over 300,00G have been built. An interesting point concerning this, unit is that it has a comparatively high ratio of 6.22 to 1, which is permitted by a specially shaped combustion. chamber. This unit,, with a capacity of 3,519 c.c., develops 72 b.h.p. at 3,000 r.p.m. Of even higher compression is the four-cylindered unit of 1,442 c.c., used in the Bedford light van, it being 6.8 to 1 This engine develops 35 b.h.p. at 3,600 r.p.m. Special features embodied in the Vulcan 6-tonner to meet overseas conditions are the engine cowling, which is insulated to prevent transference of heat into the cab, an additional air filter, and a heat-resisting flange on the petrol pump. The four-cylindered petrol engine seems to have an. ample reserve of power and a particularly efficient radiator.