Demountable Refuse Bodies Save £1,000 a Year

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

By P. A. C. Brockington, A.M.I.Mech.E.

ADEMOUNTABLE body system for the transport of salvaged and waste materials which, it is claimed, will save Stoke-on-Trent Cleansing, Salvage and Transport Department at least £1,000 a year, has been developed by Mr. R. C. Totty, cleansing superintendent and transport manager.

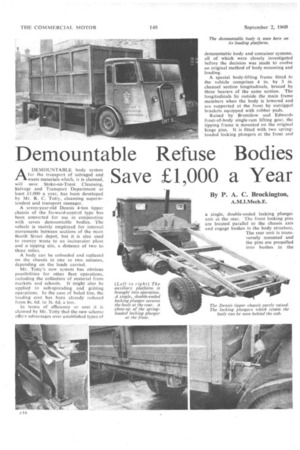

A seven-year-old Dennis 4-ton tipper chassis of the forward-control type has been converted for use in conjunction with seven demountable bodies. The vehicle is mainly employed for internal movements between sections of the main Booth Street depot, but it is also used to convey waste to an incinerator plant and a. tipping site, a distance of two to three miles.

A body can be unloaded and replaced on the chassis in one to two minutes, depending on the loads carried.

Mr. Totty's new system has obvious possibilities for other fleet operations, including the collection of material from markets and schools. It might also be applied to salt-spreading and gritting operations. In the case of baled tins, the loading cost has been already reduced from 8s. 6d. to 3s. 6d. a ton.

In terms of efficiency or cost it is claimed by Mr. Totty that the new scheme offers advantages over established types of demountable body and container systems. all of which were closely investigated before the decision was made to evolve an original method of body mounting and loading.

A special body-lifting frame fitted to the vehicle comprises 4 in. by 3 in. channel section longitudinals, braced by three bearers of the same section. The longitudinals lie outside the main frame members when the body is lowered and are supported at the front by outrigger! brackets equipped with rubber pads.

Raised by Brornilow and Edwards front-of-body single-ram lifting gear, the tipping frame is mounted on the original hinge pins, It is fitted with two springloaded locking plungers at the front and a single, double-ended locking plunge' unit at the rear. The front locking, pins are located parallel to the chassis axis and engage bushes in the body structure, The rear unit is transversely mounted and the pins are propelled into bushes in the side members of the body sub-frame. Any type of bodY may be mounted on the tipping frame.

Because the body is mounted on a tipping frame, the lifting gear can be employed in such a way that transferring the body from the stand to the chassis can be completed with the aid of a single 5-in.-diameter roller on the inside of each body side member.

Of the seven bodies, six are of the wood-framed type based on a steel frame. They have five channel-section crossbearers and a pair of 'guide rails, with radiused lead-in sections. The bodies are interchangeable and provide the same floor height as the standard units. Internal dimensions are: length, 12 ft., width, 6 ft. 8 in. and depth, 5 ft.

Steel for Clinker A special all-steel body of the same size is employed for handling clinker. The wooden bodies are lined with .16-gauge steel sheet, and the sides are braced externally by robust timber members.

Each body stand is based on eight rolled-steel-joist posts, embedded in concrete, which support 3-in, by 3-in. angle-section runners. These are ramped 24. in. In the ease of the stands employed for mounting laden bodies, an auxiliary ramp section is used to eliminate shock loads on the vehicle chassis when a body is being transferred from the stand.

Other features of the stands include a wheel stop, formed by a concrete block and 8-in, wooden guide boards. Average clearance between the wheels and each guide board is in.

The body weighs 19 cwt., which, reduces the overall weight of the complete vehicle by 1 cwt. when compared with the tipper with a conventional all-steel body. Approximate combined cost of a body and stand, including installation, is £200.

When the prime • mover chassis is backed under a stand-mounted .body for loading, the driver is assisted in aligning the vehicle wheels by -a white line on the ground. Loading is performed simply by raising the lifting frame .about 8 in. until it contacts the front cross-members of the frame and by driving the vehicle forward with the body supported at the rear by the two rollers.

These then move down the ramped stand runners until they contact the main members of the lifting frame. When heavy loads are handled, the two auxiliary ramp units, which arc hinged to base plates, are placed in position after the rear wheels of the vehicle have moved past the end of the main stand structure. Locking pins are engaged when the vehicle is clear of the stand.

Of the five body stands at the main Booth Street depot, one is located in the textile-baling shed, another in the paperbaling section and one more near the bottle-sorting platform. The .remaining two, stands are adjacent to the tin-baling press. There are also two stands at the incinerator plant, one of which is normally employed for mounting the allsteel body.

No Added Effort Surplus material from the paper-baling section is conveyed to the incinerator-for separation of the cardboard and .disposal of the waste material. The cardboard is then loaded direct into the body employed for transferring textile-baling

waste to the incinerator. Clinker is loaded into the steel body which is regularly emptied on a local tipping site.

Operators in the baling sheds can load the bodies with no more physical effort than that required by normal handling, and it is notable that the concentration of waste in the waiting bodies saves valuable space.

Chassis and body features were evolved by Mr. Tony and are covered by a provisional patent. He intends to market the system for specialized and general applications.