A Fire-fighter for Aeroplane-factory Protection

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

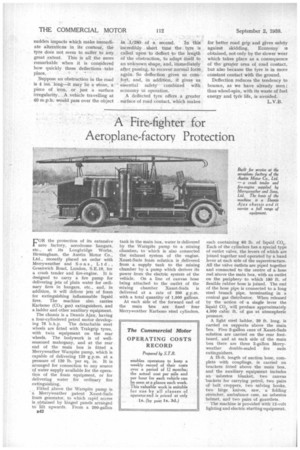

FOR the protection of its extensive aero factory, aerodrome hangars, etc., at its Longbridge Works, Birmingham, the Austin Motor Co., Ltd., recently placed an order with Merryweather and Sons, Ltd., Greenwich Road, London, S.E.10, for a crash tender and fire-engine. It is designed to carry a fire pump for delivering jets of plain water for ordinary fires in hangars, etc., and, in addition, it will deliver jets of foam for extinguishing inflammable liquid fires. The machine also carries Karbono (COy gas) extinguishers, and a ladder and other auxiliary equipment.

The chassis is a Dennis Ajax, having a four-cylindered petrol motor develop ing 75 b.h.p. The detachable steel wheels are fitted with Trakgrip tyres, with twin equipment on the rear wheels. The bodywork is of wellseasoned mahogany, and at the rear end of the main box is fitted a Merryweather Warspite pump, which is capable of delivering 120 g.p.m. at a pressure of 120 lb. per sq. in. It is arranged for connection to any source of water supply available for the operation of the foam equipment, or for delivering water for ordinary fire extinguishing.

Fitted above the Warspite pump is a Merryweather patent Xaust-Suds foam generator, to which rapid access is obtained by hinged panels arranged to lift upwards. From a 200-gallon tank in the main box, water is delivered by the Warspite pump to a mixing chamber, to which is also connected the exhaust system of the engine. Xaust-Suds foam soluticn is delivered from a supply tank to the mixing chamber by a pump which derives its power from the electric system of the vehicle. On a line of canvas hose being attached to the outlet of the mixing chamber Xaust-Suds is delivered at a rate of 200 g.p.m. with a total quantity of 1,000 gallons.

At each side of the forward end of the main box are fixed four Merryweather Karbono steel cylinders,

each containing 60 lb. of liquid CO2. Each of the cylinders has a special type of outlet valve, the levers of which are joined together and operated by a hand lever at each side of the superstructure. All the valve outlets are piped together and connected to the centre of a hose reel above the main box, with an outlet on the periphery to which 180 ft. of flexible rubber hose is joined. The end of the hose pipe is connected to a long steel branch pipe, terminating in a conical gas distributor. When released by the action of a single lever the liquid. CO2 will produce approximately 4,000 cubic ft. of gas at atmospheric pressure.

A light steel ladder, 20 ft. long, is carried on supports above the main box. Five 2-gallon cans of Xaust-Suds solution are carried on the rear footboard, and at each side of the main box there are three 2-gallon Merryweather double-sealed fire suds extinguishers.

A 15-ft. length of suction hose, complete with couplings, is carried on brackets fitted above the main box, and the auxiliary equipment includes an asbestos blanket, two canvas buckets for carrying petrol, two pairs of bolt croppers, two salving hooks, two large knives, saw, a folding stretcher, ambulance case, an asbestos helmet, and two pairs of gauntlets.

The Machine is provided with 12-volt lighting and electric starting equipment.