The Value of Deflection in Tyres

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

Capacity of the Lowpressure Tyre to Absorb Shock. Why Fixed Volume is of More Importance than Fixed

Pressure

DEFLECTION is the root idea behind the pneumatic tyre. It is to this feature—much more than to springs, shock-absorbers, and buoyant upholstery—that we owe the comfort of modern travel. Designers of both tyres and vehicles are, to-day, more than ever, endeavouring to reduce road shocks at their point of origin—the tyres— rather than by purely mechanical devices.

In tyre design, the capacity for deflection is made greater by increasing the air space of the tyre. It is a fixed volume of air, rather than a fixed pressure, which is necessary to carry the weight of a vehicle.

Volume and Pressure.

If, therefore, this volume be housed in a tyre having a large air space it will be at a lower pressuie than if it be contained in a tyre of small air space, but, nevertheless, because the volume of air is there, it will support the weight of the vehicle.

Suppose, for the sake of illustration, that an air volume of 7 cubic ft. per tyre is necessary to support a certain vehicle when fully laden. if this air be compressed into a tyre of small girth, the pressure may possibly be in the region of 90 lb. per sq. in., but if a tyre of greater air space be used, the volume of air will probably not exceed 55 lb. per sq. in.

This is the essential difference between high-pressure and low-pressure tyres, for it must be remembered that such enormous reductions in running pressures can be effected only by building tyres of special construction which are capable of withstanding considerable deflection.

Let us see what happens when we travel along a bumpy road. When a vehicle is in motion, all road shocks are delivered in the form of an upward blow through the tyris, springs, chassis, etc., and, ultimately, to the driver. The severity of these blows increases with the speed, and that is why we have to " crawl" along a bad road. By travelling slowly we give our tyres a chance to adapt themselves to the surface irregularities and we thus avoid that uncomfortable upward blow.

Shock Absorption.

We all know, however, that impact can be reduced if one or other of the colliding bodies be of a yielding nature, hence the buffers on trains. So, if our tyre be capable of considerable deflection, as a result of its low air pressure, the energy of the upward impact will be absorbed and will travel upwards in a muchmodified form.

A perfect example is provided by

the tennis ball. If a hard, weilinflated ball be dropped on the ground it will bounce high because it has only a small deflection capacity and cannot absorb the shock

of ground impact, but if a soft ball be dropped it will, to some extent, absorb the shock, and will not bounce so far. The features which we seek in tyres are the reverse of those which we require of tennis balls.

Thus, an adequate deflection reduces road shocks, by preVenting the tendency to bounce. It does more than that, however. It enables the tyre to vary its radius between the hub centre and the road surface in such a manner that, when passing over irregularities, the height of the obstruction is partly absorbed by the resilience of the tyre.

When Deflection is Absent.

If a 3-in, brick lay in the road, and a steel-tyred cart wheel passed over it, the unyielding tyre would • be lifted to the full height of the brick. This would lift the axle, and, in turn, the whole body on that side of the vehicle, to a height of 3 ins., not allowing for any spring deflection, but if a low-pressure pneumatic tyre ran over the brick the obstruction would be partly absorbed. The tyre would deflect towards the brick, thus shortening the effective radius of the wheel. If the normal radius of the tyre from hub-centre to ground was 16 ins., it is quite possible that when passing over the obstruction this would be reduced to 14 ins. The tyre would deflect and absorb 2 ins. of the height of the brick. Consequently, the axle would be lifted only 1 in., which is equal to the height of the obstacle less the amount of tyre deflection.

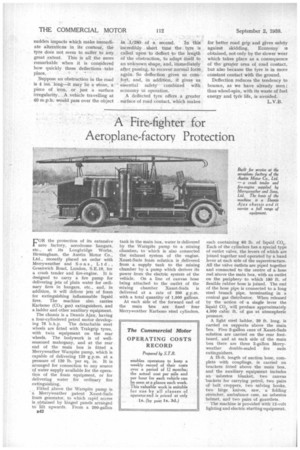

The respective comparisons between a steel tyre and a pneumatic tyre are shown in the accompanying illustrations.

An interesting point about deflection with regard to tyres is the speed with which a tyre yields to an obstacle, and the speed of its recovery to normal. Yet, despite these sudden impacts which make immediate alterations in its contour, the tyre does not seem to suffer to any great extent. This is all the more remarkable when it is considered how quickly these deflections • take place.

Suppose an obstruction in the road is 4 ins, long—it may be a stone, a piece of iron, or just a surface irregularity. A vehicle travelling at 40 m.p.h. would pass over the object

in .1/180 of a second. In this incredibly short time the tyre is called upon to deflect to the length of the obstruction, to adapt itself to an unknown shape, and, immediately after passing, to recover normal form again. So deflection gives us comfort, and, in addition, it gives us essential safety combined with economy in operation.

A deflected tyre offers a greater surface of road contact, which makes for better road grip and gives safety against skidding. Economy is obtained, not only by the slower wear which takes place as a consequence of the greater area of road contact, but also because the tyre is in more constant contact with the ground.

Deflection reduces the tendency to bounce, as we have already seen: thus wheel-spin, with its waste of fuel energy and tyie life, is avoided.

L.V.B.