WHAT CAN WE LEARN

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

FR A AMERICAN BUS DESIGN?

PERATORS of 50,000 buses and coaches in the United States, not being content with having secured from tram and train 'interests 'a large percentage of increased passenger traffic, are out for still more, and, incidentally, better net profits. The fight for business, which has been waged with increasing success in recent years, is a stiff one, made so by keen competition from long-established tram and railway systems and by increasing taxes, and regulation by federal and state operators and public utility commissions.

Heretofore, patronage has been won by the coach and bus mainly by reason of the convenience of city buses operated on routes not otherwise served by public conveyance, and by inter-city fares which were lower than those charged by the railways. Superior schedule speeds, the ability to load and discharge passengers at the kerb, and the avoidance of delays caused by breakdowns demonstrated the advantages of the bus so effectually that trams have given place to buses in hundreds of cities in the United States, including New York and Chicago. Similarly, numerous branch railways have suspended operation where it was found that the decreasing passenger s32 and freight traffic, lost to motor coaches and lorries, made -continued operation unprofitable.

Nevertheless, bus and coach-operating companies realize that,' to hold their present patronage and to win new business in the face of a railway fare based on a fiat rate of Id. (2 cents) per mile that prevails in large territories of the Country, but which will be increased to 2 cents in the north-eastern territory in the late summer, they must offer their passengers a degree of comfort and a speed schedule comparable to that afforded by the railways with their streamlined and air-conditioned trains and greatly speeded-up running times. Motor coaches, although capable of a speed in excess of 60 m.p.h., cannot maintain an average above -30 m.p.h. over a long route. This is because of state laws restricting speed, and the stops which have to be made at two-hour to three-hour intervals for passengers to obtain meals and to rest.

The invasion of the coach and bus into the realms of city trams and steam and electric railways has resulted in a wide diversity of coach and bus design. There are models of both large and small buses for city work, de luxe buses a33

for suburban traffic, and large super-coaches fcr longdistance inter-city travel. The last-named type is built and equipped to serve routes of 1,000 miles or more, as all large cities in the great expanse of the United States are connected by motor-coach lines. From the Atlantic to the Pacific coast is 3,000 miles and from the Canadian border to Old Mexico and the Gulf of Mexico 1,200 miles. Some passengers make these transcontinental trips of five days without breaking the journey en route to sleep at a hotel, and many spend two or more days'in the coaches, sleeping in their clothes in the comfortable, high-backed, reclining seats.

Competition has been responsible for the strenuous efforts which have been made to obtain maximum operating efficiency and economy, combined with improved time schedules, vehicle appearance, and passenger comfort, safety and convenience. Most new models, of all types, arc of single-deck design and are known as street cars. The body extends to iihe front bumper ; there is no engine bonnet, so that the body can be arranged farther forward on the axles to give greater seating capacity between the wheels and thus promote increased riding comfort. The design also affords better visibility for the driver.

There is a growing tendency to locate the power unit at the rear of the body, or under the floor in the centre of the vehicle. Some of the new coach and bus models are powered with oil engines. Weight reduction, in most makes,, is accomplished by the use of light all-metal bodies built di steel tubing, light alloys and aluminium sheet.

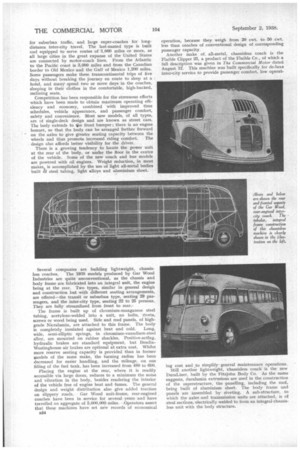

Several companies are building lightweight, chassisless coaches. The 1938 models produced by Gar Wood Industries are quite unconventional, as the chassis and body frame are fabricated into an integral unit, the engine being at the rear. Two types, similar in general design and construction but with different seating arrangements, are offered—the transit or suburban type, seating 29 passengers, and the inter-city type, seating 22 to 25 persons. They are fully streamlined from front to rear.

The frame is built up of chromium-manganese steel tubing, acetylene-welded into a unit, no bolts, rivets, screws or wood being used. Side and roof panels, of highgrade Nicralumin, are attached to this frame. The body is completely insulated against heat and cold. Long, wide, semi-elliptic springs, in chromium-vanadium-steel alloy, are mounted on rubber shackles. Positive-acting, hydraulic brakes arc standard equipment, but BendixWestinghouse air brakes are optional at extra cost. Whilst more reserve seating capacity is provided than in former snodels of the same make, the turning radius has been decreased for easier handling, and the mileage, on one filling of the fuel tank, has been increased from 480 to 600.

Placing the engine at the rear, where it is readily accessible via large doors, reduces to a minimum the noise and vibration in the body, besides rendering the interior of the vehicle free of engine heat and fumes. The general design and weight distribution also give added traction on slippery roads. Gar Wood unit-frame, rear-engined coaches have been in service for several 'years and have travelled an aggregate of 5,000,009 •Operators assert that these machines have set new records of economical 834 operation, because they weigh from 20 cwt. to 50 cwt. less than coaches of conventional design of corresponding passenger capacity.

Another make of. all-metal, chassisless coach the Flxible Clipper 25, a product of the Flxible Co., of which a full description was given in The Commercial Motor dated August 12. This machine was built specifically for de-luxe inter-city service to provide passenger comfort, low operat ing cost and to simplify • general maintenance operations.

Still another lightweight, chassisless coach' is the new DuraLiner, built by the Fitzjohn Body Co. As the name suggests, duralumin extrusions are used in the construction of the superstructure, the panelling, including the roof, being built of aluminium sheet. The body frame and panels are assembled by riveting. A sub-structure, to which the axles and transmission units are attached, is of steel sections, electrically, welded to form an integral chassisless unit with the body structure. Power is supplied by a Chevrolet six-cylindered engine, mounted at the front under, an insulated cover inside the body. It drives through a four-speed gearbox having silent helical gears.

This DuraLiner coach is said to be approximately 10-cwt. lighter than conventional coaches of similar capacity and equipment.

In a number of makes of vehicle the engine is located beneath the floor of the machine. One such is the White, which the White Motor Co. is marketing, in a series of three-new buses powered with 12-cylindered horizontally opposed petrol .engines, the snit being carried by the chassis frame, mid-way along the length of the floor. Access is gained to it from above through a trap-door in the floor, its removal being effected by lowering the complete assembly. This design was pioneered by the White concern and was engineered specifically for speedy, sale and economical transportation of large paSsenger loads in Metropolitan areas. The three models are 32, 36 and .40passenger capacities and are in operation in New York City,'. Chicago, San Francisco, Los Angeles and other big cities.

High Power-weight Ratio.

Rapid acceleration and deceleration were the chief objec. tives Of the designers and these features were attained by increasing the cylinder capacity and horse-power and decreasing body .weight. The bodies are constructed entirely of light steel, aluminium alloys and aluminium sheets, wood being used only as' a floor material. . More than 1,500 separate body parts were eliminated and the body simplified and refined by the employment of new ideas in multi-purpose aluminium extrusions. Interior quietness is obtained by sound-proofing the inside with a sprayed-on composition of cork and asbestos. On test, this type of coack has covered 1,000 ft. from a standing start, passing through all gears, iti 23.5 seconds and has attained a speed of 50 m.p.h. in 27.6 seconds.

To give operators a choice of power unit suitable for either level or hilly routes, three sizes of engine are made available and these are interchangeable in the three bus models offered.

A radical development in city:type buses was announced last spring by the Twin Coach Co. This machine was designed to conquer the last remaining stronghold Of the electric tram—dense rUstf-hour transportation in congested metropolitan areas. It is a double, articulated unit mounted on eight wheels and steered by the interconnected' front and rear wheels. The seating capacity of a single-decker —53 passengers, with peak-load capacity of 120, including standing passengers—compares: favourably : with that 'of the Modern American 'train.

Despite a length of 47 ft., the turning radius of this bus is no greater than that of the conventional 35-ft. bus. Change of ' gradient at. bridge and viaduct approaches is accommodated by hinging' the bus in the centie ot its length and forming a V-shaped opening covered with a flexible rubber hood. The four, dual-tyred middle wheels are mounted on rocking axles as in S. six-wheeled Vehicle, Alternative Sources of Power.

Electric power is 'supplied by a, Hercules 175 h.p. oil .engitte, mounted transversely in a rear compartinent and coupled to an electric generator or, alternatively, from an independent source, 'the current being picked up on the ' trolleybus systern; The current is fed to tvki 90-125 li.p. electric motors, one under the floor of each -bodY nnit and geared to the two middle axles. With a maximum Speed Of 50 m.p.h., the bus is able to maintain a schedule' speed up to 14 m.p.h. in streets where the traffic is reasonably well controlled.

Since the transcontinental railroads began running airconditioned trains some five years ago, a few long-distance motor coach operators have given much attention to the problem of fully air-conditioning their vehicles. The Interstate Transit Lines, which is a co-ordination of the Chicago and North Western Stages and the Union Pacific Stages, operating over a route 2,000 miles in length from Chicago, on the shore of Lake Michigan, to Los Angeles on the Pacific Coast, took up the task more than two years ago. Its routes cross hundreds of miles of hot, dusty land in the mid-west and south-west, where travel in midsummer is most uncomfortable. Therefore, to make its coaches invitingly cool and the air in them clean and healthful, the engineers of the coach company and those of the Baker Ice Machine Co.—a mid-west manufacturer of air-conditioning equipment—collaborated in developing a suitable system for the motor coaches, with the result that the world's first fleet of air-conditioned coaches is now in regular service between Chicago and the Pacific.Coast.

Another operating company—the Santa Fe Trailways— the machines of which run over plains, mountain and desert routes in the south-west, ordered a fleet of 45 airconditioned coaches from the A.C.F. Motors Co., which is affiliated to the .American Car and Foundry Motors Co., and it took delivery of them last spring.

The systems of the Interstate Lines and A.C.F. Motors are similar in that they both employ a refrigerating fluid which is condensed from a gaseous state to a liquid state by a compressor driven by a small, four-cylindered petrol engine and by a condensing unit. The compressing and condensing apparatus is carried in a compartment under the floor of the coach.

Passage of the Air.

Fresh air is drawn into the refrigerating chamber from a point at the forward end of the roof and mixes with air withdrawn from inside the coach. It passes through filters that extract dust and pollen and deodorize the air. Then the cool, clean air is circulated through the coach body by a ventilating system. The temperature is regulated automatically by a thermostat regulation 'being under the con trol of the driver. • • Here the similarity of the system ends, for, whilst the general principles are the same, there are many differences in mechanical construction. : In the Interstate system the lightweight, petrol engine, with its self-Starter and governor, compressor, condenser and accessories, are assembled as a unit on a framework of welded lightweight tubing. This is supported on rubber wheels to abiorb vibration and, for inspection and adjustment, can be rolled out from under the floor on 'removable channels.

Draughtless circulation of the air is effected by delivering cooled air between the steel roof and a 'false roof, which is provided with numerous minute perforations.. These perforations break up the air current on entry into the vehicle. Air within the coach. is changed completely every three minutes, The same ventilating system circulates heated air in cold weather.

Engine Under the Floor.

The A.C.F.-Carrier system is installed in square-fronted 37-passenger coaches built for air-conditioning. These vehicles are powered by Hall-Scott 180 h.p. petrol engines, mounted beneath the floor and short-coupled by a straightline driving shaft to the rear axle. The compressing-condensing equipment is assembled as a unit on a rigid subframe hung on rubber mountings from the underfraine of the coach on the right-hand side, near the passenger entrance. Suitable doors give convenient access to it.

The unit consists of an air-cooled condenser, two condenser fans that force air over the finned tubes of the condenser, a four-cylindered 9} h.p. petrol engine, a threecylindered refrigerant compressor, and various automatic control valves in the piping.

The evaporating, or air-conditioning unit at the front of the roof has, in addition to the evaporator, a thermostatic control valve, two air-circulating fans driven by a h.p. electric motor, and fresh-air filters. The fans have two speeds—high speed for summer cooling and low speed for winter, warm-air circulation. A heating coil, using hot water from the engine cooling system, is incorporated in the evaporator to warm the air in cold weather, a thermostatic valve controlling the rate of flow of hot water through the coil. In addition, there are two recirculating-type, hotair heaters on the coach floor under the seats, one near the front and the other in the rear, which also derive their heat from the engine cooling water. H.W.P.